Key Questions Answered in this Section

- What is mustard stalk and how is it used as biomass?

- How much mustard stalk is generated annually in India?

- What are the key characteristics of mustard stalk as a bioenergy feedstock?

- What are the benefits of using mustard stalk for biofuel production?

- What are the challenges associated with using mustard stalk as biomass?

- How are mustard stalks used in industrial heating and power generation?

- What industries in India use mustard stalks as an alternative fuel?

- What is the difference between raw mustard stalks and briquettes in terms of characteristics?

- How is mustard stalk stored to prevent degradation?

- What are the main regions in India where mustard stalks are abundantly available?

- Is it possible to directly use mustard stalks in boilers?

Introduction

Mustard stalk, the residual biomass left after harvesting mustard seeds, is a promising feedstock for bioenergy production. Rich in lignocellulosic material, mustard stalks can be efficiently converted into biofuels, biogas, and other value-added products.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Its high availability in mustard-growing regions makes it a cost-effective and sustainable energy source. Utilizing mustard stalk as biomass not only aids in reducing agricultural waste but also supports the transition to renewable energy, minimizing environmental impact.

Let us look into the price, availability, and proximate analysis of mustard stalk briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Total Mustard Stalk Generation in India

India generates approximately 21 million tonnes of mustard stalk residues annually. This makes it a significant biomass feedstock, especially in central and north Indian regions where mustard is widely cultivated.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of mustard stalk briquettes and pellets reveals their suitability for combustion in boilers.

| Characteristic | Raw Biomass | Briquette Form |

| Gross Calorific Value | __ | 3600 Kcal/kg |

| Moisture Content | 12% | 8% |

| Ash Content | 4.5% | 8% |

| Silica Content | 2-5% | 3-5% |

| Volatile Matter | 77% | 67% |

| Fixed Carbon | 13% | 15% |

| Bulk Density | 210 Kg/m3 | 650 Kg/m3 |

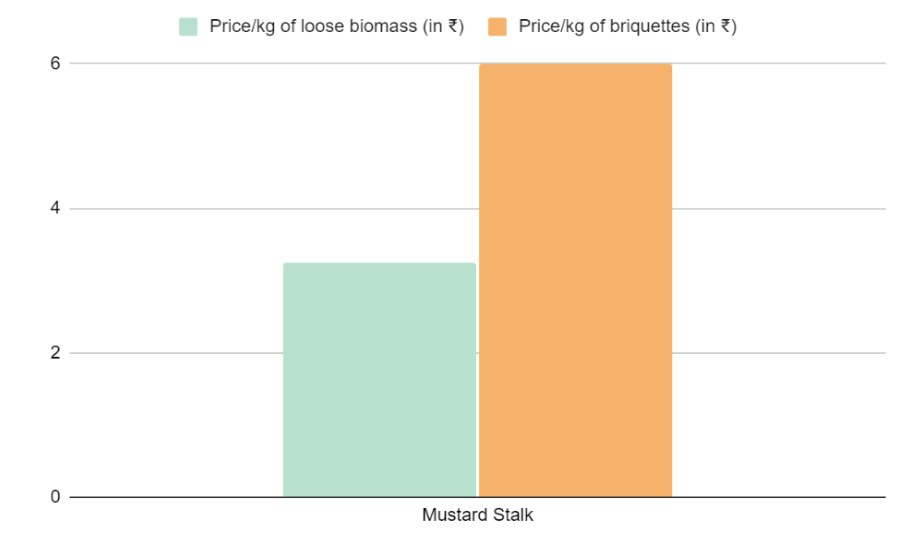

| Price | ₹3-3.5 per kg | ₹6 per kg |

Seasonality

Main Growing Season (Rabi):

- Sowing Period: September-October

- Harvesting Period: February-March

- Ideal Conditions: Thrive in cool, dry weather during growth and dry, clear weather at maturity for the best oil content.

Optimal Sowing Period for Mustard Varieties

1. Toria (Early-Sown Mustard)

- Sowing Time: Mid to late September.

- Reason: Avoids the risk of frost damage.

2. Sarson & Rai (Traditional Mustard Varieties)

- Sowing Time: First fortnight of October.

- Reason: Ensures optimal yield and quality.

Climate Preferences ?️

- Growth Period: Prefers cool, dry weather.

- Maturity: Needs dry, clear weather for the highest oil yield.

- Precipitation Needs:

- Annual Rainfall: 350-450 mm.

- Drought Sensitivity: Mustard and rapeseed are sensitive to prolonged dry conditions.

Prices

- Mustard stalk is one of the least expensive feedstocks in India, with raw biomass prices ranging between ₹3 to ₹3.5 per kg, making it highly competitive compared to other feedstocks like sawdust or groundnut shell. The price of briquettes is ₹6 per kg.

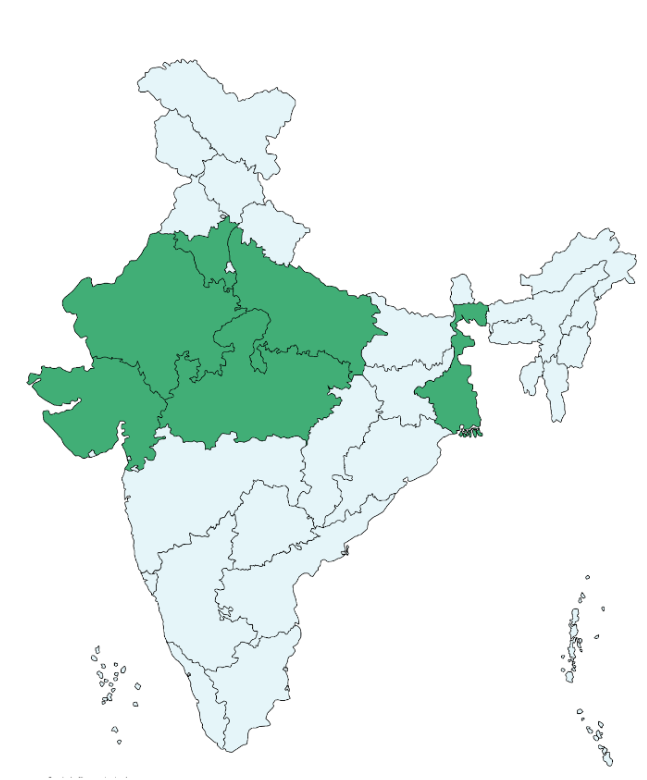

Regional Availability

Understanding the availability of mustard stalks across different regions aids in planning effective transport and logistics for their distribution

The following are the top six states in India where mustard stalks are abundantly available, along with key regions within those states:

| State | Mustard Production (MTPA) | Key Regions |

| Rajasthan | 5.5 | Kota, Bharatpur, Alwar |

| Madhya Pradesh | 1.7 | Morena, Gwalior, Shivpuri |

| Haryana | 1.4 | Mahendragarh, Hisar, Rewari, Bhiwani, Sirsa, Jhajjar, Mewat |

| Uttar Pradesh | 1.0 | Etawah, Mainpuri, Farrukhabad |

| West Bengal | 0.75 | Alipurduar, Cooch Behar, Dakshin Dinajpur, Howrah, Malda |

| Gujarat | 0.5 | Banaskantha, Patan, Mehsana |

Uses of Mustard Stalk

Current Uses

- Animal Fodder: Processed into fodder for livestock, offering a use for agricultural waste.

- Soil Amendment: Used as mulch or compost to improve soil fertility and structure.

Emerging Uses

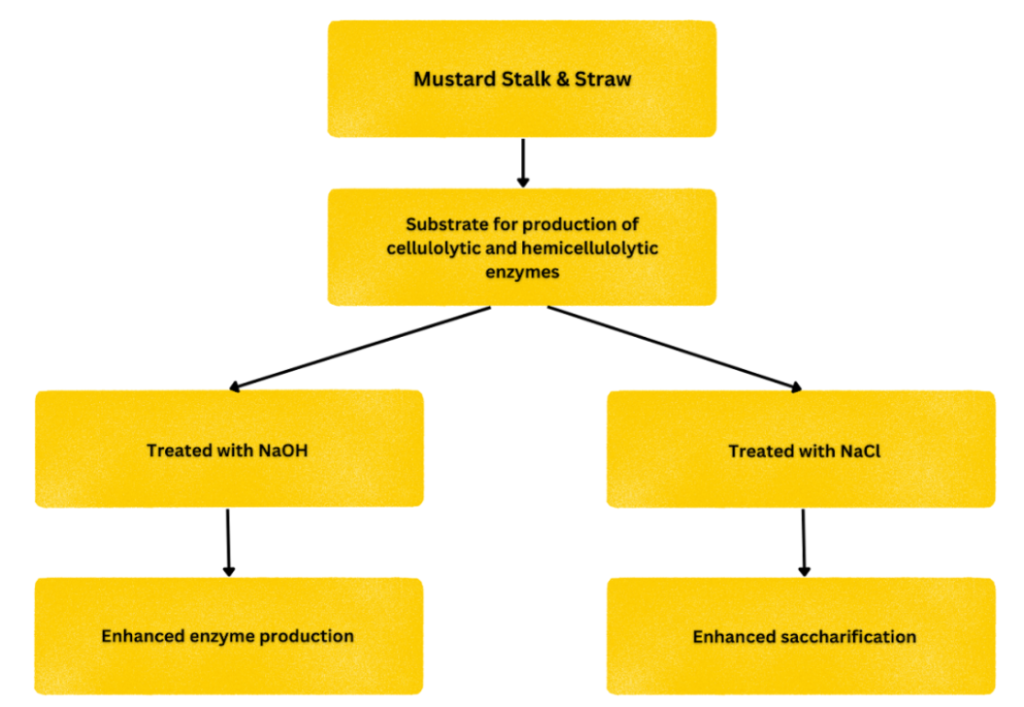

- Enzyme Production: Used as a substrate for producing cellulolytic and xylanolytic enzymes by filamentous fungi.

- Bioethanol Production: Saccharified into sugars for generating bioethanol as a renewable fuel source.

Storage of Mustard Stalk

Proper storage ensures that mustard stalk briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions

- Moisture content: Mustard stalks typically have 10-20% moisture content at harvest, which needs to be reduced to 8-10% for optimal storage to prevent fungal growth and decay.

- Storage duration: Mustard stalks can be stored for up to 6-12 months if properly dried and stored in dry, ventilated conditions, as excessive moisture can lead to degradation.

- Storage methods: Farmers and biomass processors in India commonly use covered barns, open-air stacks with protective covering (tarpaulin), or silos for storage.

- Volume availability: India produces around 10-12 million tonnes of mustard crop annually, and the residue-to-grain ratio for mustard stalks is approximately 1:8, meaning significant quantities of stalks are available for biofuel.

Mustard as Feedstock – Key Challenges

- Logistics and Storage: Mustard stalks are bulky and lightweight, making transportation costly. For example, the transportation cost can account for 20-25% of the total biomass supply chain cost.

- Lack of Infrastructure: Limited availability of proper storage facilities leads to moisture accumulation, reducing the energy efficiency of the biomass. Post-harvest losses due to poor storage can range between 10-15%.

- Competing Uses: In certain regions, mustard stalks are already used as fuel in domestic heating or as animal fodder, reducing their availability for industrial purposes. Estimates suggest 30-35% of stalks are used in non-industrial applications.

- Seasonal Availability: Mustard crops are harvested only once a year, leading to a seasonal supply of stalks. The limited window creates pressure on storage and usage, with the peak harvesting season being February to April.

Mustard Stalks in Industrial Heating and Power Generation

Uses of Mustard Stalks for Industrial Heating and Power Generation

In India, mustard stalks serve as a biomass fuel that has multiple advantages:

- Industrial Heating: Mustard stalks are burned in biomass boilers to generate heat for industrial processes. This heat can be used for drying, processing, or steam generation, making them a suitable and eco-friendly alternative to fossil fuels like coal.

- Power Generation: Mustard stalks are also utilized in biomass-based power plants, particularly in states with large mustard cultivation. They are burned to produce steam, which drives turbines to generate electricity. This method contributes to decentralized energy production and helps meet the energy needs of rural and semi-urban areas.

Form in Which Mustard Stalks Are Used in Industries

Industries utilize mustard stalks primarily in the following forms:

- Loose Biomass: In regions where collection and transport are feasible, mustard stalks are used in their raw, loose form. However, transporting bulky, loose stalks can be costly and inefficient.

- Briquettes: To overcome logistical challenges, mustard stalks are often processed into briquettes—a compact form of biomass. Briquetting increases energy density, reduces moisture content, and makes storage easier.

- Pellets: Though less common in India compared to briquettes, some industries also utilize mustard stalk pellets. These cylindrical pellets are known for their high combustion efficiency and low ash residue, making them a preferred choice for modern biomass boilers.

Boilers Using Mustard Stalks

In India, biomass boilers designed for agricultural residues are capable of burning mustard stalks. Key features of these boilers include:

- Efficiency: Advanced biomass boilers have an efficiency range of 70-80%, making them a sustainable choice compared to traditional coal-fired boilers.

- Types: Fixed-bed combustion, fluidized-bed combustion, and moving-grate combustion boilers are the most common types that can handle mustard stalks. Fluidized-bed boilers are particularly popular for their ability to burn a variety of biomass fuels with high efficiency.

- Emission Control: These boilers often include pollution control equipment like electrostatic precipitators (ESPs) and bag filters to ensure compliance with emission standards, making them environmentally friendly.

Amount of Mustard Stalks Being Used by Industries for Industrial Heating

- Estimated Usage: According to a report by the Biomass Energy Development Association of India, around 20 million tonnes of mustard stalks are produced annually in India. Out of this, approximately 1.5 million tonnes are used for biomass-based industrial heating and power generation.

- Energy Output: One tonne of mustard stalks can generate around 4,200-4,500 kWh of energy. This makes it a viable fuel for small to medium-scale industries in mustard-growing regions like Rajasthan, Haryana, and Uttar Pradesh.

- Cost Efficiency: Industries using mustard stalks save about 20-25% in fuel costs compared to coal. The average price of processed mustard stalk briquettes is INR 6000 per tonne, which is significantly cheaper than coal or furnace oil.

Prominent Industries Using Mustard Stalks for Industrial Heating

Several industries in India have adopted mustard stalks as an alternative fuel source. Some notable ones include:

- Textile Industry:

- Textile mills in Gujarat and Rajasthan are increasingly using biomass boilers fueled by mustard stalks to generate steam for dyeing and processing fabrics.

- The industry’s shift to mustard stalks has reduced reliance on conventional fossil fuels, cutting energy costs and enhancing sustainability.

- Food Processing:

- Mustard stalks are widely used in food processing plants, especially for drying spices, pulses, and grains.

- The mustard-growing regions have a natural advantage, allowing local food processing units to source biomass cheaply and easily.

- Brick Kilns:

- Biomass-fueled brick kilns are gaining popularity in India, where mustard stalks replace traditional fuels like wood and coal.

- This transition has reduced the environmental impact of brick-making while providing a consistent and cost-effective heat source.

- Paper and Pulp:

- The paper industry has also begun integrating mustard stalks into their energy mix. Biomass boilers using agricultural residues, including mustard stalks, generate the heat needed for pulping processes.

- Agro-Based Industries:

- Many agro-based industries, such as oil mills and agro-processing units, have installed biomass boilers that use mustard stalks, leading to reduced operational costs and carbon footprints.