Key Questions Answered in this Section

- What is the projected growth rate of the biomass gasifier market in India from 2023 to 2028?

- Which factors are driving the growth of biomass gasifiers in India?

- What are the primary applications of biomass gasifiers in the Indian context?

- Who are the key players in the Indian biomass gasifier industry?

- What types of feedstocks are commonly used for biomass gasification in India?

- What are the emerging feedstocks being explored for biomass gasification?

- What recent innovations have been introduced in the biomass gasifier sector?

- Which sectors are benefiting from the adoption of biomass gasifiers in India?

- What are the key challenges facing the biomass gasifier industry in India?

- What central and state-level policies support the growth of biomass gasifiers in India?

- What new technologies are being introduced in biomass gasification in India?

- How much does it cost to set up a biomass gasifier plant in India?

- What is the future growth potential for biomass gasifiers in India?

- How is the gas produced from biomass being used in India?

- How does biomass gasification work to produce energy?

- Which states in India are adopting biomass gasifiers the most?

India’s Bio-economy Opportunities Service from Biobiz – Click to See All Opportunities

This detailed section @ BioBiz explores the potential of biomass gasifiers as a sustainable energy solution, and also provides a scan of the Indian biomass gasification & gasifier market.

Biomass gasification involves the incomplete combustion of organic materials, producing a combustible gas known as producer gas. This technology offers an economically viable and renewable energy source, especially in areas with high petroleum fuel prices or unreliable supplies. The Indian Biomass Gasifier market is emerging as a critical segment in the country’s renewable energy landscape, offering sustainable solutions for energy production.Investment in Biomass Gasifier technology in India has seen a surge due to increasing awareness of its environmental benefits and government incentives.

Table of Content

- Introduction

- Market Potential of Biomass Gasifiers

- Key Players in the Biomass Gasifier Industry

- Overview of Technology and Processes

- Feedstocks for Biomass Gasifiers in India

- Emerging Feedstocks for Biomass Gasification

- Recent Innovations in the Biomass Gasifier Sector

- End-Use Applications

- Sectors Benefiting from the Biomass Gasifier Sector

- Key Drivers and Opportunities

- Key Challenges

- Central and State-Level Policies

- Business Models

- Key Stakeholders and Companies

- Conclusion

Introduction

Biomass gasifiers are equipment that transform biomass into gaseous forms. The process, known as biomass gasification, involves the incomplete combustion of biomass, resulting in the production of a combustible gas mixture known as producer gas.

Biomass gasification provides an economically viable system, especially in areas where the price of petroleum fuels is high or where supplies are unreliable. It offers a sustainable solution for energy production, contributing to the reduction of greenhouse gas emissions and promoting the use of renewable resources.

Market Potential of Biomass Gasifiers

Biomass gasifiers hold the potential for converting organic matter into clean and efficient energy, contributing to renewable energy goals and waste management solutions. The Biomass Gasifier market growth in India is expected to achieve a significant CAGR, driven by rising demand for cleaner and more efficient energy sources.

With a steadily expanding market size, the Indian Biomass Gasifier industry is attracting investments from both domestic and international players.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

- Market size: The Indian biomass gasifier market was estimated at USD 40 million in 2023 and is projected to reach USD 120 million by 2028, growing at a CAGR of 21.5%.

- Growth drivers

- Abundant availability of agricultural residues and other organic waste.

- Growing demand for decentralized power generation and clean cooking fuels in rural areas.

- Rising awareness about the environmental benefits of biomass gasification.

- Major applications

- Power generation for rural communities and industries.

- Thermal applications for drying, cooking, and industrial processes.

- Biochar production for soil amendment and carbon sequestration.

Companies in the Biomass Gasifier Industry in India

| Category | Company | Role |

| Producers | Ankur Gasifiers | Designs and manufactures a wide range of biomass gasifiers for various applications |

| Radhe Gasifiers | Specializes in manufacturing biomass gasifiers for industrial and rural energy needs | |

| Infinite Energy | Provides innovative gasifier solutions with a focus on efficiency and sustainability | |

| Thermax Limited | Designs, manufactures, and commissions biomass gasification systems (complete solutions) | |

| Sterling Biofuels Pvt. Ltd | Offers customized gasifier solutions for industrial and commercial sectors | |

| Excel Industries Limited | Manufactures and supplies gasifiers for power generation and industrial applications | |

| Prakash Fabricators Pvt. Ltd | Provides gasifier systems for agricultural and rural communities | |

| M.A.C. Engineering Pvt. Ltd | Offers gasifiers for heat and power generation, catering to diverse needs | |

| Raw Material Supply Stakeholders | KRIBHCO (Krishak Bharati Cooperative Limited) | Supplies agricultural residues (paddy straw, wheat straw) |

| Wood Pellet Manufacturers Association of India (WPMAI) | Represents wood pellet producers, offering a sustainable biomass fuel source | |

| Energy Plantation & Research Limited (EP&RL) | Cultivates and supplies energy crops specifically for gasification | |

| Municipal Corporations (e.g., Chennai Municipal Corporation) | Provides segregated organic waste for waste-to-energy gasification projects | |

| Sawmills and Wood Processing Industries | Offer wood waste (sawdust, shavings) as biomass feedstock | |

| Technology Solution Providers | Godrej Appliances Limited | Provides advanced control systems for efficient gasifier operation and monitoring |

| Gasifiers International Private Limited | Specializes in downdraft gasifier design and implementation | |

| Biomass Research Center (BRC) – IIT Delhi | Conducts R&D on advanced gasification technologies | |

| Thermax Engineering | Offers expertise in process integration for optimal utilization of biomass gas |

Overview of Biomass Gasifier Technology and Processes

Biomass gasifiers convert organic matter like wood, agricultural residues, and other waste materials into producer gas, a mixture of gases mainly composed of hydrogen, carbon monoxide, and methane. This versatile fuel can be used for various applications such as power generation, heat production, and transportation fueling. Here’s a breakdown of the technology and processes involved. Recent advancements in Biomass Gasifier production technology are helping to increase efficiency, reduce costs, and improve the scalability of gasification processes in India.The development of innovative Biomass Gasifier technology in India is enabling the sector to meet the increasing energy demands of rural and urban areas.

Types of Gasifiers

- Downdraft Gasifiers: Air is drawn downwards through the fuel bed, producing producer rich in hydrogen and nitrogen.

- Updraft Gasifiers: Air flows upwards through the fuel bed, resulting in the gas with higher CO and lower hydrogen content.

- Fluidized Bed Gasifiers: Fine biomass particles are suspended in a hot air stream, creating a highly efficient and fast gasification process.

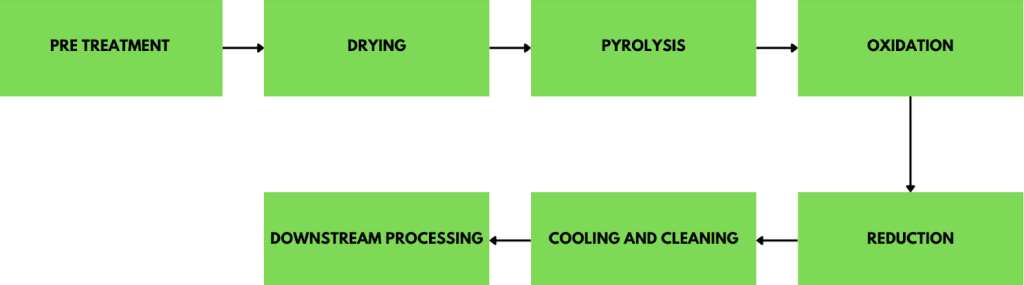

Process Overview

Biomass gasifiers offer a fascinating technology for converting organic waste like agricultural residues, wood chips, or food waste into a combustible gas called syngas. This versatile fuel holds immense potential for generating power, heat, and even transportation fuels. Let’s delve into the intricate steps involved in this process.

1. Feedstock Preparation

- Selection and Sourcing: The first step starts with choosing suitable biomass feedstock. Factors like moisture content, size, and composition influence efficiency and gasifier performance. Wood chips, agricultural residues, or dedicated energy crops are often preferred.

- Pre-treatment: The feedstock may undergo processing like crushing, grinding, and drying to optimize its size and moisture content for efficient gasification. This ensures proper flow within the gasifier and enhances the quality of the produced syngas.

2. Gasification

- The heart of the process lies in the gasifier itself. Several types exist, but two common ones are:

- Downdraft gasifier: Air is drawn downwards through the hotbed of biomass, generating syngas rich in hydrogen and nitrogen.

- Updraft gasifier: Air flows upwards through the biomass, resulting in syngas with higher CO content and lower hydrogen content.

- Inside the gasifier, the prepared feedstock undergoes a series of thermochemical processes at high temperatures (typically above 700°C) in the absence of sufficient oxygen for complete combustion. These processes include

- Drying: Moisture in the feedstock evaporates due to the heat from the lower zones.

- Pyrolysis: As the temperature rises, the biomass decomposes into volatile gases and char (charcoal).

- Oxidation: A limited amount of air is introduced, allowing a portion of the char to burn and provide heat for the process.

- Reduction: The remaining char reacts with the hot gases like steam and carbon dioxide, producing hydrogen, carbon monoxide.

3. Cooling and Cleaning

- The hot syngas exiting the gasifier contain impurities like tar, dust, and particulates. These can damage downstream equipment and hinder the usability of the syngas.

- Therefore, the producer gas is passed through a series of cooling and cleaning systems. Water scrubbers, cyclones, and filters are commonly used to remove these impurities and cool down the syngas to a suitable temperature for further processing or utilization.

4. Downstream Processing (Optional)

- Depending on the intended end-use, the syngas may undergo further treatment

- Upgrading: To increase the hydrogen content and heating value, processes like reforming or water-gas shift reaction can be employed.

- Cleaning: Additional cleaning steps may be needed to remove any remaining impurities for specific applications like fueling internal combustion engines.

Feedstocks- States

According to the data presented by the Union Minister of Power and New and Renewable Energy in the Lok Sabha on August 5, 2022, the total installed capacity of gasifiers in India is about 1,74 MWeq (megawatt equivalent).

Based on this information, the top 10 states to start a biomass gasifier business in India are Haryana, Tamil Nadu, Karnataka, Assam, Arunachal Pradesh, Manipur, Tripura, Kerala, Mizoram, and Bihar.

| State | Reasons |

| Haryana | – Seventh-largest producer of biomass in India. High power demand and deficit. – Supportive policy and incentives. – The only state in the region to have installed biomass gasifier plants. |

| Tamil Nadu | – Seventh-largest producer of biomass in India. – High power demand and deficit. – Supportive policy and incentives. – The only state in the region to have installed biomass gasifier plants. |

| Maharashtra | – Third-largest producer of biomass in India. – High industrial and agricultural power demand Supportive policy and incentives. – Leading producer of jatropha, a potential biomass gasification feedstock |

| Karnataka | – Fifth-largest producer of biomass in India. – High industrial and agricultural power demand. – Supportive policy and incentives. – A pioneer in biomass gasification from Pongamia, a native tree species. |

| Gujarat | – Ninth-largest producer of biomass in India – High industrial and agricultural power demand. – Supportive policy and incentives. – Vibrant entrepreneurial culture and high per capita income. |

| West Bengal | – Sixth-largest producer of biomass in India – High rural and urban power demand – Supportive policy and incentives – Promising producer of biodiesel from mustard, a potential biomass gasification feedstock. |

| Madhya Pradesh | – Tenth-largest producer of biomass in India. – Moderate power demand and surplus. – Supportive policy and incentives. – Hub for biomass gasification from non-edible oils such as Karanja, neem, and mahua. |

| Rajasthan | – Tenth-largest producer of biomass in India. – Moderate power demand and surplus. – Supportive policy and incentives. – Hub for biomass gasification from non-edible oils such as Karanja, neem, and mahua. |

| Uttar Pradesh | – The largest producer of biomass in India. – High power demand and deficit. – Supportive policy and incentives. – The largest producer of sugarcane, a potential biomass gasification feedstock. |

| Bihar | – Eighth-largest producer of biomass in India. – High power demand and deficit Supportive policy and incentives. – Potential producer of biomass gasification from rice bran, a by-product of rice milling. |

Feedstocks for Biomass Gasifiers in India

| Category | Examples | Description |

| Agricultural Residues | Rice straw, wheat straw, sugarcane bagasse, corn stover, cotton stalks, Napier grass, sweet sorghum, bamboo | Readily available from farms and plantations, offering a renewable energy source. |

| Forestry Residues | Sawdust, wood chips, bark, wood shavings, fallen leaves, pine needles, logging residues | Contributes to waste management and resource recovery, offering alternative fuel sources. |

| Additional Potential Feedstocks | Algae, invasive aquatic plants (water hyacinth), paper mill sludge, textile waste (subject to suitability) | Emerging options require further research and development for wider adoption. |

Emerging Feedstocks for Biomass Gasification in India

While traditional feedstocks like agricultural and forestry residues play a significant role in India’s biomass gasification sector, several emerging options hold potential for future growth and sustainability.

1. Algae

- Description: Microscopic aquatic organisms with high growth rates and the ability to capture carbon dioxide.

- Potential: Offers a promising source of clean and renewable biomass. Algae can be cultivated in controlled environments, minimizing land use concerns compared to traditional crops. Their high lipid content can be converted into biofuels or upgraded to biogas through gasification.

- Challenges: Requires substantial research and development to optimize cultivation methods, harvesting processes, and cost-effectiveness for large-scale production.

- Examples: Sea6 Energy (Bengaluru, Karnataka): Focuses on cultivating algae for biofuels and biomass gasification. They are researching ways to optimize algae cultivation and processing for energy production.

2. Invasive Aquatic Plants

- Description: Fast-growing aquatic plants like water hyacinths can pose ecological challenges.

- Potential: Offers a potential solution for weed management while generating biomass for gasification. These plants can be harvested and processed into biogas, contributing to waste management and energy production.

- Challenges: Requires efficient and sustainable harvesting methods to prevent further ecological harm. Research is needed to determine the most suitable gasification technologies for processing these specific feedstocks.

- Example: EnviGreen (Bengaluru, Karnataka): Utilizes invasive plants like water hyacinths for biomass gasification, turning ecological challenges into energy solutions.

3. Paper Mill Sludge

- Description: A by-product of the paper manufacturing process, often landfilled or incinerated.

- Potential: Offers an opportunity to divert waste from landfills and recover energy through gasification. Paper mill sludge has a cellulose content suitable for conversion into biogas.

- Challenges: It may require pre-treatment to remove contaminants and ensure efficient gasification. Stringent regulations and quality control measures are crucial to managing potential emissions from processing this waste stream.

- Example: ITC Paperboards and Specialty Papers Division (Bhadrachalam, Telangana) uses paper mill sludge for energy recovery through gasification, diverting waste from landfills and generating biogas.

4. Textile Waste

- Description: Discarded fabrics and textile scraps generated by the textile industry.

- Potential: Offers a sustainable solution for managing textile waste, preventing landfilling, and contributing to a circular economy. Depending on the composition (synthetic vs. natural fibers), appropriate gasification technologies may be required to ensure efficient conversion.

- Challenges: The sorting and segregation of different types of textile waste is crucial. Synthetic fibers may require co-gasification with other feedstocks or advanced gasification technologies to optimize energy recovery.

- Example: Arvind Limited (Ahmedabad, Gujarat): Exploring gasification of textile waste to manage waste and generate energy, supporting circular economy practices.

Recent Innovations in the Biomass Gasifier Sector

The biomass gasification sector is continuously evolving, with several exciting innovations emerging to address existing challenges and improve efficiency, sustainability, and scalability. Here are some noteworthy developments.

1. Advanced Gasifier Designs

- Fluidized Bed Gasifiers: Fine biomass particles are suspended in a hot air stream, creating a highly efficient and fast gasification process with improved control over syngas composition.

- Example: Ankur Scientific Energy Technologies (Vadodara, Gujarat): Develops fluidized bed gasifiers for efficient biomass conversion.

- Microwaves and Radio Frequency Heating: These technologies are being explored for their potential to selectively heat and convert biomass, potentially enhancing efficiency and reducing emissions.

- Example: Research at IIT Delhi (Delhi): Investigates microwave and RF heating for selective biomass conversion, aiming to enhance efficiency.

2. Improved Feedstock Processing

- Pretreatment Techniques: Advanced techniques like torrefaction and hydrothermal carbonization are being explored to improve the energy density, hydrophobicity (water resistance), and flow characteristics of biomass, leading to better gasification efficiency and reduced emissions.

- Example: TERI (The Energy and Resources Institute, New Delhi): Explores torrefaction and hydrothermal carbonization to improve biomass characteristics for gasification.

- Co-gasification: Blending various biomass feedstocks, including waste materials and dedicated energy crops, can optimize gasifier performance and address feedstock availability challenges.

3. Integration with Other Technologies

- Combined Heat and Power (CHP) integrating biomass gasifiers with CHP systems allows for simultaneous electricity and heat production, maximizing energy utilization and efficiency.

- Example: Husk Power Systems (Patna, Bihar): Integrates biomass gasifiers with CHP systems for simultaneous electricity and heat production.

- Carbon Capture and Storage (CCS) capturing and sequestering carbon dioxide emissions from the gasification process can further enhance the sustainability of the technology by mitigating its environmental impact.

- Example: Research at IISc Bangalore (Bengaluru, Karnataka) develops CCS technologies for gasification processes to mitigate environmental impact.

- Biochar Production: Integrating the production of biochar, a charcoal-like material with potential benefits for soil health and carbon sequestration, with gasification can create a more circular and sustainable process.

- Example: BioEnergy India (Chennai, Tamil Nadu) combines biochar production with biomass gasification for soil health and carbon sequestration benefits.

4. Digitalization and Data Analytics

- Sensors and monitoring systems: Integrating sensors and real-time data monitoring allows for improved process control, optimization, and predictive maintenance of gasifier systems.

- Example: Agni Energy (Bengaluru, Karnataka): Utilizes real-time sensors and data monitoring for optimized gasifier operation and predictive maintenance.

- Machine learning and artificial intelligence: AI and machine learning can help optimize gasifier operation, predict potential issues, and improve syngas quality and yield.

- Example: Research at IIT Bombay (Mumbai, Maharashtra): Applies AI and machine learning to optimize gasifier performance, improving syngas quality and yield.

End-Use Applications of Biomass Gasifiers in India

Biomass gasifiers offer a versatile solution by converting biomass into a combustible gas that can be utilized for various applications. Here’s an overview of some key end-use applications in India.

1. Power Generation

- Grid-connected power plants: Large-scale biomass gasifier plants (MW capacity) generate electricity that can be fed into the national grid, contributing to renewable energy sources.

- Example: Husk Power Systems (Bihar): Operates biomass gasifier plants providing electricity to the national grid, enhancing renewable energy sources.

- Captive power plants: Industries like textiles, food processing, or sugar mills can install biomass gasifier systems to generate electricity for their operations, reducing reliance on the grid and achieving cost savings.

- Example: Mysore Paper Mills (Karnataka): Uses biomass gasifier systems to generate electricity for its operations, reducing grid dependence and achieving cost savings.

- Mini-grids: In remote, off-grid communities, smaller biomass gasifier plants can be used to establish mini-grids, providing a reliable and sustainable source of electricity for households and essential services.

- Example: Desi Power (Bihar): Implements biomass gasifier mini-grids in remote communities to provide reliable and sustainable electricity.

2. Thermal Applications

- Industrial process heat: Various industries, such as brick kilns, ceramic production, and food processing, can utilize the heat generated from biomass gasification for their industrial processes, replacing conventional fossil fuels.

- Example: Ankur Scientific (Vadodara, Gujarat) supplies biomass gasifiers to brick kilns and ceramic industries to replace conventional fossil fuels with sustainable heat sources.

- Drying applications: Agricultural products like grains, spices, and tea can be efficiently dried using biomass gasifier-powered dryers, improving product quality and shelf life.

- Example: Kohinoor Foods (Haryana) uses biomass gasifier-powered dryers for processing grains and spices, enhancing product quality and shelf life.

- Space heating: In colder regions, institutions like schools, hospitals, or community centers can utilize biomass gasifiers for space heating, providing a sustainable and cost-effective solution.

- Example: Ladakh Renewable Energy Development Agency (LREDA, Ladakh) implements biomass gasifiers for space heating in schools and hospitals, providing sustainable heating solutions in cold regions.

3. Cooking and Heating

- Institutional kitchens: Large kitchens in institutions like hotels, hospitals, or canteens can adopt biomass gasifiers to cook meals, reducing reliance on LPG and contributing to environmental sustainability.

- Example: Auroville (Tamil Nadu): Adopts biomass gasifiers in community kitchens to cook meals, reducing reliance on LPG and promoting environmental sustainability.

4. Other Applications

- Syngas production: An advanced form of biomass gasification can generate syngas, a mixture of gases, which can be utilized for various purposes, including producing synthetic fuels or chemicals.

- Example: Chanderpur Works (Haryana): Develops biomass gasifiers for syngas production, used for synthetic fuel and chemical manufacturing.

Sectors Benefiting from the Biomass Gasifier Sector in India

| Sector | Benefits | Description |

| Agriculture | Farmers: Increased income, improved soil health | Selling residues or using digestate as fertilizer |

| Agro-processing industries: Waste management, energy generation | Utilizing processing residues in gasifiers, achieving energy independence | |

| Power Sector | Power generation, decentralized power | Supplementing grid power, providing electricity to off-grid communities |

| Waste Management Sector | Municipal Corporations: Waste diversion, energy generation | Diverting organic waste from landfills, generating electricity from waste |

| Industries: Industrial waste reduction | Converting organic waste into energy for waste management | |

| Environment and Climate Change | Reduced greenhouse gas emissions, improved air quality | Cleaner alternative to fossil fuels, minimizing harmful air pollutants |

| Rural Development | Employment generation, improved livelihood | Creating jobs in various sectors, enhancing economic activities |

Key Drivers and Opportunities in the Biomass Gasifier Sector

The biomass gasification sector presents exciting opportunities for clean energy generation, waste management, and economic development, driven by several key factors.

Drivers

- Growing demand for renewable energy: Increasing concerns about climate change and depleting fossil fuel resources are fueling the global demand for clean and sustainable energy sources. Biomass gasification offers a versatile renewable option for power generation, heat production, and potentially transportation fuels.

- Abundant and diverse feedstock availability: Organic waste like agricultural residues and industrial waste provide readily available and renewable feedstock for gasification, promoting resource recovery and circular economy principles.

- Government support and incentives: Many governments are implementing policies and programs to promote biomass gasification, offering financial assistance, tax breaks, and feedstock availability schemes. Government policies on Biomass Gasifier are designed to encourage private sector participation and improve production capacity across the country. Regulatory measures ensure that Biomass Gasifier production aligns with India’s broader renewable energy and climate action goals.

- Technological advancements: Continuous improvements in gasifier design, efficiency, and emissions control are making the technology more cost-effective and environmentally friendly.

- Decentralized power generation: Biomass gasifiers can provide off-grid power solutions in remote areas, enabling energy access and promoting rural development.

Opportunities

- Market expansion: The global biomass gasifier market is expected to grow significantly in the coming years, presenting ample opportunities for new businesses and investments.

- Waste-to-energy solutions: Collaborations with industries and municipalities to utilize waste as feedstock can create mutually beneficial partnerships and address waste management challenges.

- Carbon credit generation: Integrating carbon capture and utilization technologies with gasification can generate additional revenue streams and contribute to climate change mitigation.

- Biochar production: Combining gasification with biochar production offers multiple benefits, including soil improvement, carbon sequestration, and diversified revenue streams.

- Mobile gasification units: Deploying portable gasifiers can cater to off-grid needs, remote applications, and specific feedstock processing requirements.

- Data-driven optimization: Utilizing data and analytics to optimize gasifier performance and resource utilization can improve efficiency and profitability.

- Blockchain integration: Implementing blockchain technology can ensure transparency and traceability in feedstock sourcing, carbon credits, and energy production, enhancing trust and sustainability.

Key Challenges of Starting a Business in the Biomass Gasifier Sector

While the biomass gasifier sector offers exciting opportunities, launching a business in this field comes with its own set of challenges. Here are some key obstacles to consider.

1. High Upfront Investment Costs

- Setting up a biomass gasification system requires significant capital investment for equipment, infrastructure, and feedstock procurement. This can be a major hurdle for new businesses, especially those without access to substantial funding or established financial backing.

2. Feedstock Availability and Logistics

- Ensuring a reliable and consistent source of suitable biomass feedstock is crucial for operational success. This involves building relationships with suppliers, managing the logistics and transportation of often bulky materials, and potentially facing seasonal fluctuations in availability.

3. Technical Expertise and Skilled Workforce

- Operating and maintaining a gasifier system effectively requires specialized knowledge and expertise in areas like gasification technology, feedstock characteristics, and emissions control. Finding and retaining qualified personnel with the necessary technical skills can be challenging.

4. Regulatory Compliance and Permitting

- Navigating the complex regulatory landscape related to environmental permits, emissions standards, and waste management can be time-consuming and costly. Obtaining the necessary approvals and meeting compliance requirements can add significant complexity to starting and operating a biomass gasification business.

5. Market Competition and Price Volatility

- The market for biomass gasification is still developing, and competition from established players or alternative clean energy solutions can be present. Additionally, the price of biomass feedstock as well as the price for heating or power generated from producer gas and other products derived from the process can be volatile, impacting revenue streams and profitability.

6. Technology Maturity and Risk Perception

- While advancements are continuous, biomass gasification technology is still evolving compared to more established energy sources. Though the risks are not high in the producer gas generating biomass gasifiers that are currently used in India, there are uncertainties for investors and potential customers who may be unfamiliar with the technology.

7. Public Perception and Social Acceptance

- Concerns about potential environmental impacts like air emissions, noise pollution, or land-use issues surrounding biomass feedstock production can create public resistance or hinder wider adoption of the technology. Addressing these concerns and ensuring transparent communication are crucial for gaining public and community support.

8. Long-Term Sustainability and Circular Economy Practices

- Ensuring the sustainable sourcing and management of biomass feedstock is essential for the long-term viability of the business. This involves implementing responsible practices throughout the entire value chain, considering factors like biodiversity, soil conservation, and potential indirect land-use change.

Key challenges of Biomass Gasifier adoption include ensuring a steady supply of feedstock and addressing the high initial investment costs for technology implementation. Despite competitive pressures in the Biomass Gasifier market, the potential for high profits and returns makes it a lucrative investment option.

Central and State-Level Policies Supporting Biomass Gasification in India

| Policy | Description | Impact |

| National Bio Energy Programme (NBEP): – Subsidy Scheme for Installation of Biogas Plants | Provides CFA (30-50%) for setting up grid-connected or off-grid biomass gasifier power plants. | Reduces project cost, fostering adoption. |

| Scheme on Biomass Gasifier-based Power Generation for Captive Power and Thermal Applications | Offers financial assistance (up to 20%) for captive power and thermal applications using biomass gasifiers. | Encourages industries to adopt biomass gasification for self-reliance and cost savings. |

| Waste to Energy Programme | Offers financial support for establishing waste-to-energy plants, potentially including those using biomass gasification. | Promotes waste management and clean energy generation. |

| State-Level Renewable Energy Policies | Many states offer incentives like feed-in tariffs for electricity generated from biomass gasifiers, ensuring a guaranteed price for producers. | Enhances project viability and attracts investment. |

| State-Level Industrial Policies | Some states provide various concessions and incentives like land subsidies or tax benefits to encourage industries to adopt biomass gasification for captive power generation. | Lowers operational costs and makes gasification more attractive for industries. |

Business Models for the Biomass Gasifier Sector in India

| Model | Description | Focus | Application | Example |

| Independent Power Producers (IPPs) | Design, build, own, and operate power plants, selling electricity to the grid. | Profitability through reliable operation, feedstock procurement, and favorable tariffs. | The company sets up a 5 MW plant with farmers, selling electricity to a state distribution company. | Husk Power Systems (Bihar): Designs, builds, owns, and operates power plants, selling electricity to the grid. They have set up several 5 MW plants in collaboration with local farmers, selling electricity to state distribution companies. |

| Captive Power Plants | Industries install gasifiers for self-use (electricity/heat). | Reduce reliance on grid power and achieve potential cost savings. | A textile mill or food processing unit invests in a gasifier for on-site waste conversion to energy. | Mysore Paper Mills (Karnataka): Uses biomass gasifiers to generate electricity for their operations, reducing reliance on the grid and achieving cost savings. |

| Rural Electrification/DESCOs | Companies/organizations establish mini-grids using gasifiers to provide electricity to off-grid communities. | Meet basic energy needs, offer affordable power, and create income opportunities. | Social enterprise sets up a community-managed mini-grid using a pay-per-use or subscription model. | DESI Power (Bihar): Establishes mini-grids using gasifiers to provide electricity to off-grid communities. They use a pay-per-use or subscription model to meet basic energy needs and create income opportunities. |

| Waste-to-Energy Developers | Companies specialize in setting up waste-to-energy plants, often including biomass gasification. | Solve waste management challenges, generate energy, and potentially recover valuable materials. | A private company contracted by a city for a waste-to-energy plant using gasification and other technologies to process organic waste. | Thermax Limited (Pune, Maharashtra): Specializes in setting up waste-to-energy plants, including biomass gasification, to solve waste management challenges, generate energy, and recover valuable materials. They have been contracted by several cities to process organic waste using these technologies. |

Key Stakeholders and Companies in the Biomass Gasifier Ecosystem

The biomass gasifier ecosystem comprises a diverse set of players who contribute to the development, deployment, and operation of this technology. Understanding these stakeholders is crucial for navigating the sector and identifying potential collaboration opportunities.

1. Technology Providers

- Gasifier manufacturers:

- Example: Ankur Scientific Energy Technologies (Vadodara, Gujarat) designs, manufactures, and supplies various types of biomass gasifier systems.

- Engineering and consulting firms: These firms offer expertise in feasibility studies, system design, and project development, supporting the planning and implementation of biomass gasification projects.

- Example: Praj Industries (Pune, Maharashtra): Offers expertise in feasibility studies, system design, and project development for biomass gasification projects.

2. Feedstock Suppliers

- Forestry companies: Forest management organizations can be potential suppliers of wood chips or other woody biomass suitable for gasification.

- Example: Greenply Industries (Tinsukia, Assam) supplies wood chips and other woody biomass suitable for gasification.

- Agricultural businesses: Farms and agricultural cooperatives can provide agricultural residues like straw, corn stover, or bagasse as feedstock.

- Example: Balrampur Chini Mills (Balrampur, Uttar Pradesh) provides agricultural residues like bagasse as feedstock for gasification.

- Waste management companies: Partnerships with waste management companies can enable the utilization of organic waste streams like yard trimmings for gasification.

- Example: Eco Wise Waste Management (Noida, Uttar Pradesh) partners with biomass gasification projects to utilize organic waste streams.

3. Project Developers and Operators

- Independent power producers (IPPs): These companies develop, own, and operate biomass gasification plants, often generating electricity and selling it to the grid.

- Example: Husk Power Systems (Bihar): Develops, owns, and operates biomass gasification plants, generating electricity for the grid.

- Industrial companies: Industries with high energy demands may invest in and operate on-site gasification units to meet their own energy needs.

- Example: ITC Limited (Hyderabad, Telangana): Invests in on-site gasification units to meet its own energy needs.

- Municipalities and utilities: Local authorities can explore utilizing biomass gasification for waste management or generating renewable energy for their communities.

- Example: Brihanmumbai Municipal Corporation (BMC, Mumbai, Maharashtra): Explores biomass gasification for waste management and renewable energy generation.

4. Investors and Financiers

- Venture capitalists and private equity firms: These entities may invest in promising new technologies and companies within the biomass gasifier sector.

- Example: Infuse Ventures (Ahmedabad, Gujarat): Invests in new technologies and companies within the biomass gasifier sector.

- Government agencies and development banks: Public institutions can offer financial incentives, loans, and grants to support the development and deployment of biomass gasification projects.

- Example: Indian Renewable Energy Development Agency (IREDA, New Delhi): Offers financial incentives, loans, and grants for biomass gasification projects

5. Research Institutions and Universities

- Universities and research institutes: These institutions play a crucial role in advancing technology through research and development activities, exploring new feedstocks, and improving gasifier efficiency and sustainability.

- Example: Indian Institute of Science (IISc, Bengaluru, Karnataka): Conducts research and development in biomass gasification, exploring new feedstocks and improving gasifier efficiency.

- Industry associations and non-governmental organizations (NGOs): These organizations promote the development and responsible use of biomass gasification by advocating for policies, conducting research, and raising awareness of the technology’s potential.

- Example: Biomass Energy and Sugarcane Industry Promotion Association (BESIPA, New Delhi): Promotes the development and responsible use of biomass gasification through advocacy, research, and raising awareness.

Strategic Initiatives Adopted by Indian Industries in the Biomass Gasifier Sector

1. Captive Power Generation

- Industries with high energy needs: Industries like rice mills, textiles, ceramics, and brick manufacturers are increasingly opting for biomass gasifiers for captive power generation.

- Motivation: Reduces reliance on grid power, lowers energy costs, and provides a sustainable solution for utilizing agricultural or processing residues internally.

- Example: A sugar mill in Maharashtra installing a biomass gasifier system to utilize bagasse (sugarcane residue) for electricity and process heat generation.

2. Waste-to-Energy (WtE) Focus

- Municipal Solid Waste Management: Companies specializing in waste management are developing Waste-to-Energy plants, with some incorporating biomass gasification technology alongside other options.

- Objective: Tackles the challenge of increasing urban solid waste and contributes to energy generation with a focus on environmental management.

- Example: A waste management company partnering with a city corporation to set up a WtE plant using gasification along with segregation and composting facilities.

3. Collaboration and Partnerships

- Biomass suppliers and technology providers: Industries seeking biomass gasification establish supply chain partnerships with farmers, aggregators, and technology/equipment providers for reliable feedstock and robust technical solutions.

- Joint ventures and partnerships: Companies sometimes form joint ventures or collaborations to leverage expertise and share project risks for developing larger-scale biomass gasifier projects.

4. Technology Exploration and Innovation

- Optimizing existing systems: Industries constantly explore ways to improve the efficiency and reliability of their biomass gasifier systems through process optimization and feedstock management.

- New gasification technologies: Some companies are investing in the research and development of new gasification technologies, including advanced gas cleaning systems and integration with renewable energy sources like solar.

5. Policy Engagement and Advocacy

- Shaping supportive policies: Industry associations like the BioEnergy Society of India (BESI) and individual companies actively participate in consultations with government bodies, advocating for favorable policies and incentives that promote the growth of the biomass gasifier sector.

Challenges and Future Directions

- Economic viability: Industries carefully analyze upfront investment costs and the long-term economic feasibility of biomass gasifier projects.

- Government support: Further policy support from state and central government in terms of feed-in tariffs, financial incentives, and clarity on WtE regulations can encourage greater adoption.

Technological advancements: Research into advanced gasifier designs, improved efficiencies, and new applications can enhance the sector’s attractiveness.

Conclusion

Biomass gasifiers represent a promising technology for transforming organic waste into clean and efficient energy, aligning with renewable energy goals and addressing waste management challenges. The Indian biomass gasifier market, projected to grow at a CAGR of 21.5% from 2023 to 2028, exemplifies the sector’s robust potential. Key growth drivers include government initiatives, the abundant availability of biomass feedstocks, and rising awareness of the environmental benefits of biomass gasification. This technology’s versatility in generating power, providing thermal applications, and producing biochar underscores its vital role in advancing sustainable energy solutions and promoting rural development.

The environmental benefits of Biomass Gasifier technology, combined with its potential to contribute to India’s energy self-sufficiency, highlight its importance in the renewable energy sector. With ongoing advancements and growing competition in the Biomass Gasifier market, industry players are well-positioned to capitalize on this expanding opportunity.