Key Questions Answered in this Section

- What is the annual production of eucalyptus bark biomass in India, and which regions contribute the most to its availability?

- How does eucalyptus bark’s calorific value and combustion efficiency compare to other common biomass sources?

- What forms of eucalyptus bark (pellets, chips, powdered) are most commonly used in industries, and why are they preferred?

- Which industries in India are the largest consumers of eucalyptus bark for industrial heating and power generation?

- What types of boilers (e.g., fluidized bed or grate boilers) are best suited for utilizing eucalyptus bark, and how do they handle its unique characteristics?

- What are the key challenges, such as high moisture content and ash production, associated with using eucalyptus bark as a biomass feedstock?

- What is the role of eucalyptus bark in co-firing applications in thermal power plants, and how does it contribute to emission reductions?

- How is eucalyptus bark processed into pellets or briquettes, and what advantages do these forms offer for storage and transport?

- What are the environmental benefits of using eucalyptus bark as a biomass fuel, particularly in terms of reducing agricultural waste and greenhouse gas emissions?

- How is eucalyptus bark being utilized in emerging applications like biochar production, activated carbon, and eco-friendly building materials?

- How is the price of eucalyptus bark determined in both loose and briquette forms, and what factors influence its cost?

- Is it possible to directly use eucalyptus bark in boilers?

Introduction

Eucalyptus bark biomass is an eco-powerhouse in the world of renewable resources. Harvested from fast-growing eucalyptus trees, this fibrous bark isn’t just an abundant byproduct but a high-energy fuel source that’s easily transformed into biofuels, biochar, and green chemicals.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Let us look into the price, availability, and proximate analysis of eucalyptus bark briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Total Eucalyptus Bark Generation in India

Every year, India sees the establishment of around 150,000 hectares of new eucalyptus plantations. With each hectare yielding an average of 60-75 tonnes over its growth span, these plantations collectively generate an impressive biomass output. Altogether, this results in roughly 10.13 million tonnes of eucalyptus biomass annually.

Given that eucalyptus bark makes up about 15% of the total tree weight, the annual eucalyptus bark generation in India is approximately 1.52 million tonnes.

Assessing the availability of eucalyptus bark involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of eucalyptus bark reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Parameter | Loose Form | Briquette Form |

| Gross Calorific Value (GCV) | —– | 3900 Kcal/kg |

| Moisture Content | 52% | 12% |

| Ash Content | 1% | 1.5% |

| Silica Content | 1-2% | 1-2% |

| Volatile Matter | 83% | 75% |

| Fixed Carbon | 16% | 17% |

| Bulk Density | 445 Kg/m3 | 650-780 Kg/m3 |

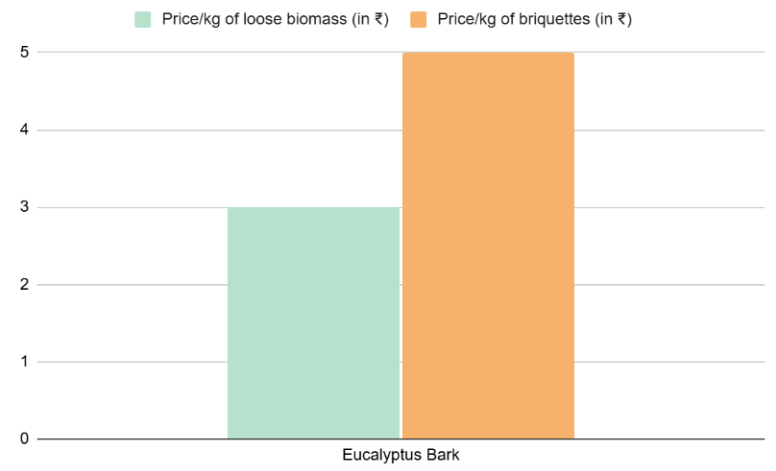

| Price | ₹3/Kg | ₹5/Kg |

Seasonality

Eucalyptus bark in India is harvested seasonally, with key activities aligning with India’s climatic variations. The ideal time for harvesting the bark begins in late winter, as growth slows and the bark peels more easily, continuing until early summer. This period generally spans from February to June, optimizing extraction quality and reducing growth disruption.

key climate requirements for cultivating eucalyptus:

- Temperature Range: Suitable growth occurs from 0 to 40°C.

- Rainfall: Ideal annual rainfall is between 500 to 3000 mm.

- Sowing Temperature: Optimal sowing conditions range from 25 to 35°C.

- Harvesting Temperature: Favorable harvesting temperatures range between 20 to 40°C.

For eucalyptus planting, the optimal time is between June and October. Transplanting seedlings is the primary sowing method.

Regional Availability

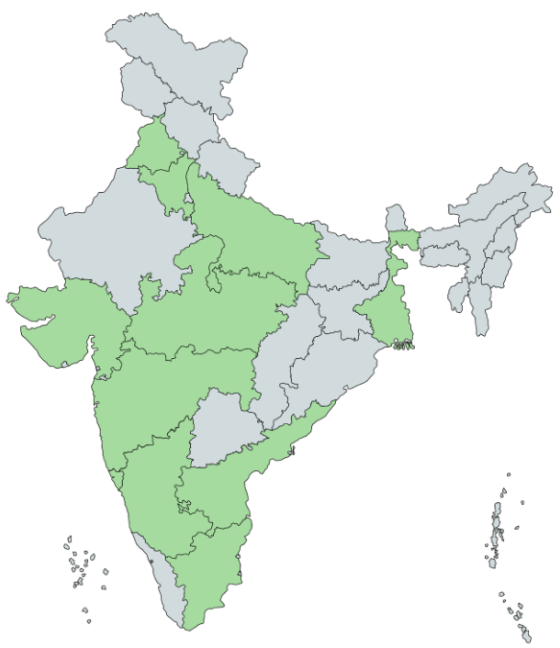

Regions with abundant eucalyptus bark availability can leverage this resource for use in boilers, promoting sustainable energy practices. Major eucalyptus growing states are Andhra Pradesh, Bihar, Goa, Gujarat, Punjab and Haryana, Madhya Pradesh, Maharashtra, Uttar Pradesh, Tamil Nadu, Kerala, West Bengal and Karnataka.

| State | Key Regions of State |

| Andhra Pradesh | Rajahmundry, Eluru, Nellore, Kavali (S), Kavali (N), Naidupet, Satyavedu, Bapatla, Visakhapatnam, Narsipatnam |

| Gujarat | Valsad, Navsari, Anand |

| Karnataka | Kolar, Tumkur, Hoskote |

| Tamilnadu | Nilgiri Hills, Pudukottai, Kodaikanal Hills |

| Haryana | Sonepat, Panipat, Kaithal, Charkhi Dadri, Bhiwani, Yamunanagar, and Rohtak. |

| Punjab | Hoshiarpur and Muktsar |

| Madhya Pradesh | Sehore, Barwaha, Dhar, Khargon, East Mandla, Sidhi, East Chhindwara, Dindori, Jhabua, and West Mandla |

| Maharashtra | Vidarbha |

| Uttar Pradesh | Terai, Prayagraj, Vindhyan |

| West Bengal | Bankura, Purulia |

| Kerala | Thiruvananthapuram, Punalur, Thrissur, Munnar, and Gavi |

Prices

- Loose Form: Eucalyptus bark in loose form is priced around ₹3 per kg, making it a more economical option compared to the briquetted form.

- Briquette Form: Briquetted barks are priced at ₹5 per kg, reflecting the added processing and density benefits for storage and transport.

- Fluctuations in eucalyptus bark price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

Uses of Eucalyptus Bark

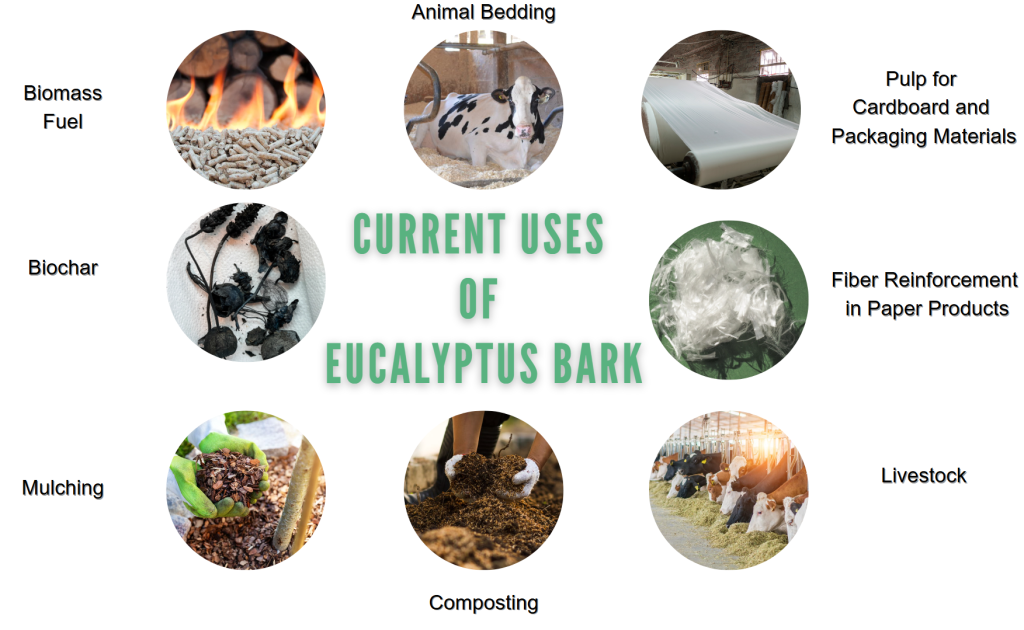

Current Uses

- Biofuel and Energy Production

- Biomass Fuel: Used as a renewable energy source in power plants, eucalyptus bark residue helps reduce reliance on fossil fuels, offering an eco-friendly alternative for heat and electricity generation.

- Biochar Production: Bark is converted into biochar, enhancing soil health and storing carbon. This biochar is widely applied in agriculture for soil enrichment.

- Agricultural and Horticultural Applications

- Mulching: Eucalyptus bark is processed into mulch, which improves soil moisture retention, controls weed growth, and moderates soil temperature in gardens and farms.

- Composting: Composting eucalyptus bark adds organic matter to the soil, though it requires careful processing due to allelopathic compounds that might inhibit certain plant growth.

- Paper and Pulp Industry

- Pulp for Cardboard and Packaging Materials: Eucalyptus bark is used to produce pulp for lower-quality paper, such as cardboard and packaging, which reduces the demand for virgin wood.

- Fiber Reinforcement in Paper Products: Eucalyptus bark’s fiber content enhances paper strength, making it suitable for durable packaging materials and other specialty paper products.

- Animal Bedding

- Livestock and Poultry Bedding Material: Shredded eucalyptus bark is commonly used for animal bedding because of its high absorbency and natural pest-repellent properties, especially in agricultural areas.

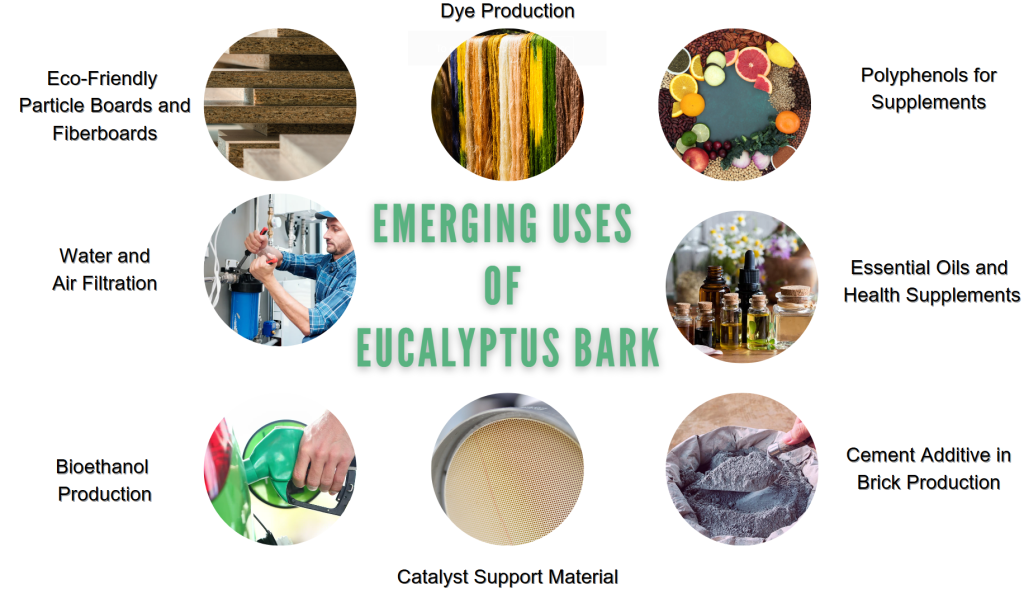

Emerging Uses

- Bioethanol Production

- Renewable Biofuel Alternative: Eucalyptus bark residue is rich in lignocellulosic material, making it a viable feedstock for bioethanol production. This offers a sustainable alternative to fossil fuels, aligning with the rising demand for green energy sources.

- Activated Carbon for Environmental Applications

- Water and Air Filtration: The bark residue can be transformed into activated carbon, which is highly effective in purifying water and air, removing heavy metals, and supporting catalytic processes in chemical industries.

- Catalyst Support Material: Activated carbon derived from eucalyptus bark offers a sustainable, low-cost option for various chemical processes requiring catalyst support.

- Construction and Composite Materials

- Eco-Friendly Particle Boards and Fiberboards: Bark residue can be processed into particle boards and fiberboards, providing sustainable, lightweight materials for construction and furniture, and reducing reliance on traditional wood sources.

- Cement Additive in Brick Production: Finely ground eucalyptus bark is used in eco-friendly bricks and cement mixtures, enhancing the structural integrity of construction materials while lowering environmental impact.

- Pharmaceutical and Medicinal Applications

- Essential Oils and Health Supplements: Eucalyptus bark contains bioactive compounds with antibacterial, antifungal, and antioxidant properties, which is why it is used in essential oils and health supplements.

- Polyphenols for Supplements: Polyphenols derived from eucalyptus bark, like tannins and flavonoids, have antioxidant properties, making them valuable as natural health supplements and for medicinal formulations.

- Natural Dye for Textiles

- Eco-Friendly Dye Production: The bark is rich in natural dye compounds, used in eco-conscious textile dyeing processes, providing soft brown, red, and yellow tones without the need for synthetic chemicals

Storage of Eucalyptus Bark

Proper storage ensures that eucalyptus bark briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions

1. Moisture Control and Ventilation

- Drying Before Storage: Ideally, eucalyptus bark biomass should be air-dried to reduce moisture content below 15-20% before storage, as high moisture can lead to fungal growth and microbial decomposition, which reduces biomass quality.

- Ventilated Storage: Ensure the storage area has good airflow to prevent moisture buildup and condensation. In enclosed storage facilities, install ventilation systems to maintain air circulation.

- Avoiding Ground Contact: Stack the biomass on pallets or a raised surface to prevent moisture absorption from the ground, which can lead to rot and degrade the material.

2. Temperature and Fire Risk Management

- Cool Storage Conditions: Store eucalyptus bark biomass in a shaded or cool area, as high temperatures combined with organic material can lead to spontaneous combustion, especially in large, dense piles.

- Temperature Monitoring: Regularly monitor the temperature within large piles of biomass, particularly if they are stored indoors. High internal temperatures are an indicator of microbial activity, which can increase fire risk.

- Fire Safety Precautions: Store biomass away from flammable materials and install fire extinguishers or sprinkler systems nearby. Large storage facilities should consider firebreaks between piles and access for emergency response if needed.

3. Pest and Fungal Prevention

- Pest-Proof Containers or Enclosures: Use pest-proof containers or enclose storage areas to prevent infestations by insects, rodents, and other pests that may be attracted to organic material.

- Fungicidal Treatment: In humid environments, treat eucalyptus bark biomass with eco-friendly fungicides to prevent mold or fungal growth, especially if it is to be stored for extended periods.

4. Stacking and Compacting

- Avoid Over-Compaction: While stacking biomass efficiently is essential to save space, avoid over-compacting the material, as this limits airflow and increases the risk of decomposition and combustion. Stack in layers, with airflow channels if possible.

- Using Mesh Bags or Crates: If possible, store in breathable bags (such as mesh bags) or crates that allow air circulation. This method is especially useful for smaller quantities or for biomass designated for immediate processing.

5. Protection from Weather and Environmental Exposure

- Covered Storage: Store eucalyptus bark biomass under a roof or tarp to protect it from rain, snow, and direct sunlight, which can leach nutrients and degrade the material’s quality.

- UV Protection: Prolonged exposure to sunlight can break down the organic matter in eucalyptus bark, so shaded or covered storage areas are ideal for preserving biomass integrity.

6. Labeling and Segregation

- Batch Labeling: If biomass is harvested at different times or from different areas, label each batch clearly to ensure quality control and monitor the age of the material.

- Segregating by Moisture Content: Store batches with similar moisture content together to prevent uneven drying and decomposition rates, especially if using biomass for high-quality applications like biofuel production.

Eucalyptus Bark as Feedstock – Key Challenges.

1. High Moisture and Resin Content

- Challenge: Eucalyptus bark has a high initial moisture content and contains resins and oils, which can make it difficult to handle and process. High moisture reduces combustion efficiency in bioenergy applications, and resins can cause issues like equipment fouling and increased emissions during processing.

- Impact: This high moisture and resin content requires additional drying and sometimes chemical treatment before the bark can be efficiently used as feedstock, increasing operational costs and time.

2. Allelopathic Compounds

- Challenge: Eucalyptus bark contains allelopathic chemicals like phenolics and terpenes, which inhibit the growth of some plants. This can be problematic if the biomass is intended for applications like composting or as mulch, as these compounds can disrupt soil and plant health.

- Impact: To use eucalyptus bark safely in agriculture or horticulture, it may need to undergo special treatments (e.g., composting to degrade the allelopathic chemicals), adding complexity and cost.

3. Ash and Mineral Content

- Challenge: Eucalyptus bark tends to produce a higher ash content upon combustion, and it contains specific minerals (e.g., potassium, calcium) that can cause slagging and fouling in combustion equipment. These minerals can also lead to equipment corrosion over time.

- Impact: The high ash and mineral content complicates combustion processes, requiring advanced or customized equipment to handle the residues and prevent damage, adding to maintenance and operational costs.

Eucalyptus Bark for Industrial Heating and Power Generation in India

Uses of Eucalyptus Bark for Industrial Heating and Power Generation

Eucalyptus bark is increasingly recognized for its potential in industrial heating and power generation in India. With its high calorific value, it serves as an efficient biomass fuel alternative, particularly in the textile, paper, and energy sectors.

- Biomass Fuel: Eucalyptus bark is primarily used as a biomass fuel for combustion in power plants and industrial boilers, contributing to sustainable energy production.

- Co-Firing: Many thermal power plants are co-firing eucalyptus bark with coal, enhancing energy output while reducing greenhouse gas emissions.

- Heat Generation: Industries utilize eucalyptus bark for direct heating applications, such as drying processes in textile manufacturing and other heat-intensive operations.

Form in Which Eucalyptus Barks Are Used in Industries

Eucalyptus bark is processed into various forms to maximize its utility in industrial applications:

- Pellets: Eucalyptus bark is compressed into pellets, which offer high density and low moisture content, making them ideal for efficient transportation and combustion.

- Chips and Shredded Bark: These forms are commonly used in industrial boilers, providing an effective and uniform feedstock for combustion.

- Powdered Bark: Finely ground eucalyptus bark is used in specific applications where rapid combustion and high surface area are advantageous.

Boilers Using Eucalyptus Bark

Several industries in India have adopted eucalyptus bark as a fuel source in their boilers. The advantages of using eucalyptus bark in boilers include:

- Efficiency: Eucalyptus bark boilers are designed to maximize thermal efficiency, often exceeding 80% efficiency in heat recovery.

- Environmental Compliance: Many modern boilers using eucalyptus bark meet stringent emission standards, making them suitable for eco-conscious industries.

- Popular Boiler Types:

- Fluidized Bed Boilers: These are widely used for burning biomass, including eucalyptus bark, due to their ability to handle a variety of feedstocks.

- Grate Boilers: Common in industrial settings, these boilers effectively combust larger pieces of biomass.

Amount of Eucalyptus Bark Being Used by the Industries for Industrial Heating

The demand for eucalyptus bark as a biomass fuel in India is on the rise. Some key data points include:

- Annual Consumption: Estimates suggest that approximately 1.5 million tons of eucalyptus bark are consumed annually by various industries in India.

- Power Generation Contribution: In the renewable energy sector, eucalyptus bark contributes to about 10% of the biomass used in power generation, indicating its growing importance in the energy mix.

Prominent Industries Using Eucalyptus Bark for Industrial Heating

Several key industries in India have integrated eucalyptus bark into their operations for heating and power generation:

- Textile Industry: With a significant focus on sustainable practices, many textile manufacturers have adopted eucalyptus bark for heat generation in dyeing and finishing processes.

- Paper Industry: The paper and pulp sector extensively utilizes eucalyptus bark not only as a raw material for pulp but also as a fuel for energy generation in their mills.

- Sugar Mills: Many sugar factories use eucalyptus bark for cogeneration, where the energy generated from burning biomass is used to power the mill and sell excess energy to the grid.

- Bioenergy Sector: Several bioenergy plants are increasingly relying on eucalyptus bark as a feedstock for biogas production and direct combustion for electricity generation.