Key Questions Answered in this Section

- What is the annual production of coriander stalk biomass in India, and which regions contribute most to its availability?

- How does the calorific value of coriander stalks compare to other agricultural residues used for industrial heating and power generation?

- What forms (e.g., pellets, chips, loose biomass) of coriander stalks are most commonly utilized in industries, and why are they preferred?

- What are the challenges associated with using coriander stalks as biomass feedstock, such as moisture content and bulk density, and how can they be addressed?

- Which industries in India are the largest consumers of coriander stalks for heating and energy production?

- What are the potential environmental benefits of replacing fossil fuels with coriander stalks in industrial applications?

- How do seasonality and limited availability impact the consistent supply of coriander stalks as a biomass feedstock?

- What advancements in technology (e.g., pelletization, gasification) are making coriander stalks a more viable option for industrial energy use?

- How are coriander stalks being utilized in emerging applications like biochar production, biogas generation, and bioactive compound extraction?

- What incentives or government initiatives are in place to promote the use of coriander stalks and similar agricultural residues in India’s renewable energy sector?

- How is the price of coriander stalks in loose form and as briquettes determined, and what factors influence the cost?

- Is it possible to directly use coriander stalks in boilers?

Introduction

Coriander stalk, often overlooked as agricultural waste, holds significant potential as a biomass feedstock due to its fibrous structure and nutrient-rich profile. Derived from the coriander plant (Coriandrum sativum), these stalks are typically discarded post-harvest, despite being a renewable source of organic material.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

When used as biomass, coriander stalks can be converted into valuable bioenergy, biofuels, or biochar through processes like pyrolysis, gasification, and anaerobic digestion. Their chemical composition, with notable cellulose and lignin content, makes them suitable for energy production, while also reducing waste and offering a sustainable alternative to fossil fuels.

Let us look into the price, availability, and proximate analysis of coriander stalk briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Total Coriander Generation in India

The country’s annual production of coriander seeds was over 847 thousand metric tons in 2023. The surplus availability is 0.26 million tonnes per annum. Assessing the availability of coriander stalk involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of coriander stalk reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Parameter | Value |

| Moisture Content | 50% |

| Ash Content | 2% |

| Silica Content | 2-5% |

| Volatile Matter | 78% |

| Fixed Carbon | 18% |

| Bulk Density | 250-300 Kg/m3 |

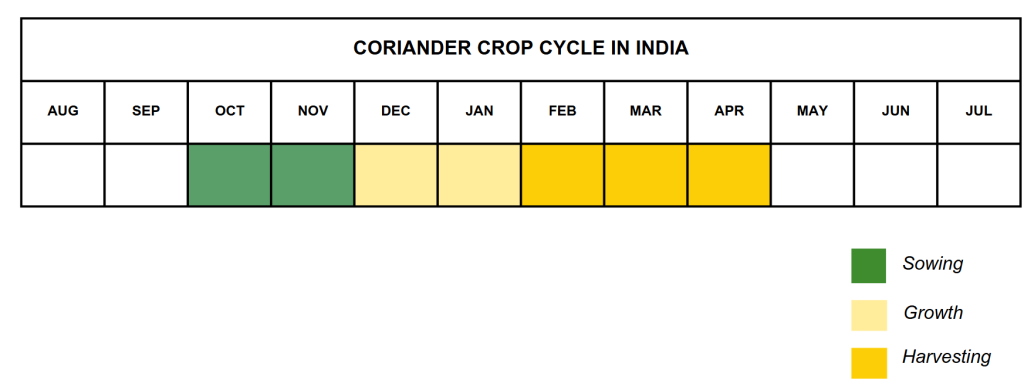

Seasonality

- Climate Requirements: Cool climate during growth; warm, dry climate at maturity.

- Soil Suitability: Can grow in most soils, but well-drained loamy soil is ideal.

- Seed Quality: Superior seed quality and higher essential oil content in colder, high-altitude regions.

- Seed Rate: 15-20 kg per hectare; seeds should be split before sowing, preserving the sprouting part.

- Sowing Season: Rabi season, from October 15 to November 15. Adjust sowing in frost-prone areas.

- Planting: Sown in rows with 30 cm spacing; early sowing affects germination, late sowing may lead to diseases.

- Maturity Period: 110-140 days; seeds turn yellowish-green and are medium-hard when mature.

- Harvest and Post-Harvest: Dry under partial shade, then separate seeds by thrashing; clean and grade seeds.

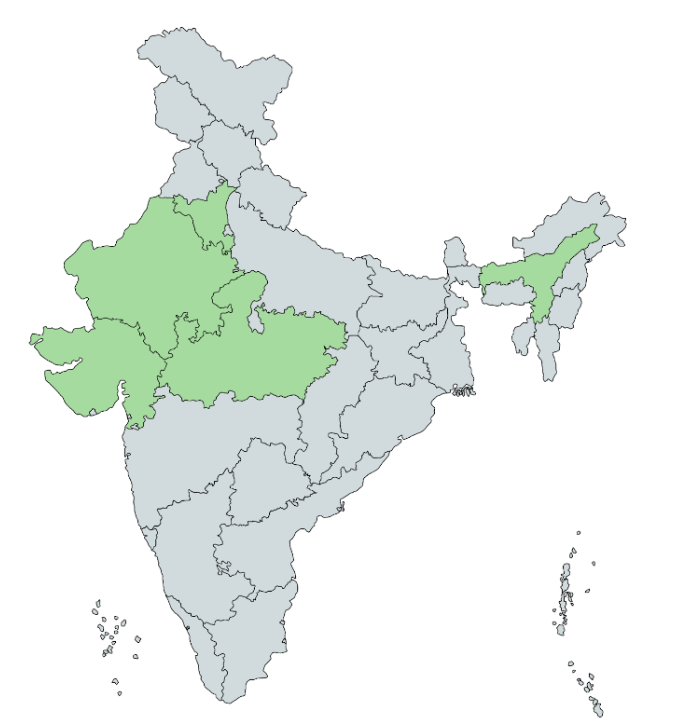

Regional Availability

Regions with abundant coriander stalk availability can leverage this resource for use in boilers, promoting sustainable energy practices. The following table lists the top 5 states and key regions of the states in India where croainder is highly available.

| State | Total Coriander Production (in MTPA) | Total Surplus Generation(in MTPA) | Key Regions of State |

| Madhya Pradesh | 3.3 | 1 | Guna, Rajgarh, Mandsaur, Agar-Malwa, and Neemuch |

| Rajasthan | 1.8 | 0.5 | Hadoti region, which includes the districts of Baran, Bundi, Jhalawar, and Kota |

| Gujarat | 1.1 | 0.3 | Rajkot, Surendranagar, Gondal, Junagarh, and Jamnagar |

| Assam | 0.03 | 0.009 | Kamrup, Karbi Anglong, N.C. Hill, Nagaon, Goalpara, and Cachar |

| Haryana | 0.004 | 0.001 | Hisar, Kaithal, Karnal, Panipat, Ambala and Jind |

Uses of Coriander Stalks

Current Uses of Coriander Stalk

- Animal Feed: Coriander stalks are commonly used as a natural, fibrous component in livestock feed, providing roughage and mild nutrient content for animals.

- Mulching and Composting: Used as organic mulch or compost material, coriander stalks help retain soil moisture, prevent weed growth, and enrich the soil as they decompose.

- Biochar Production: Coriander stalks can be pyrolyzed to produce biochar, a soil amendment that enhances nutrient retention and improves soil health.

Emerging Uses of Coriander Stalk

- Biofuel and Biogas: Research is exploring the conversion of coriander stalks into biofuel or biogas through anaerobic digestion and pyrolysis, offering a renewable alternative to fossil fuels.

- Bioactive Compounds for Pharmaceuticals: Coriander stalks contain phytochemicals that are being studied for potential antimicrobial, antioxidant, and anti-inflammatory applications in the pharmaceutical industry.

- Packaging Material: With advances in biodegradable and eco-friendly packaging, coriander stalk fiber is being tested as a raw material for creating sustainable packaging products, reducing plastic use.

Storage of Coriander Stalks

- Drying Before Storage: Coriander stalks should be thoroughly dried to reduce moisture content, which prevents mold and decay during storage. Partial shade drying is preferred to retain essential oils and quality.

- Cool, Dry Environment: Store coriander stalks in a cool, dry area to avoid moisture accumulation and pest infestation, maintaining optimal storage conditions for prolonged shelf life.

- Ventilated Containers: Use breathable or ventilated storage containers, such as mesh bags or jute sacks, to promote airflow and prevent moisture buildup, preserving the stalks’ quality.

- Avoid Direct Sunlight: Keep coriander stalks away from direct sunlight in storage, as excessive heat and light can degrade their nutrient content and essential oils over time.

- Proper storage ensures that coriander stalk briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Coriander Stalk as Feedstock – Key Challenges

- High Moisture Content: Coriander stalks, like many leafy greens, have a high moisture content, which makes them less suitable for direct combustion or gasification. This necessitates drying processes, which can be energy-intensive and costly, reducing the overall efficiency and viability as a biomass feedstock.

- Low Bulk Density: Coriander stalks are light and voluminous, which translates to low bulk density. This characteristic complicates transportation and storage, as it requires more space compared to denser biomass sources like wood or agricultural residues, raising logistical costs.

- Variability in Chemical Composition: The chemical composition of coriander stalks can vary based on factors like growing conditions, harvest time, and post-harvest handling. This variability can affect the consistency of the biofuel or bioproduct output, making it harder to standardize processing and quality control.

- Rapid Decomposition Rate: Coriander stalks decompose quickly after harvest due to their high moisture and nutrient content, making long-term storage challenging. Without immediate processing, the quality deteriorates, leading to potential losses and additional handling requirements.

- Limited Availability and Seasonality: Coriander is not cultivated in the same bulk quantities as major biomass crops (e.g., corn, sugarcane, or wood). Its seasonal and geographically limited availability restricts the feedstock supply chain, potentially causing interruptions in biofuel production cycles or requiring supplementation with other biomass sources.

Coriander Stalk for Industrial Heating and Power Generation

Uses of Coriander Stalk for Industrial Heating and Power Generation

Coriander stalks are primarily used as a biomass fuel for various industrial applications. Their high calorific value, which ranges between 3,800 to 4,500 kcal/kg, makes them an efficient energy source for heating and power generation. Industries utilize coriander stalks in:

- Boilers: As a fuel source for steam generation in various sectors, including textiles, food processing, and paper manufacturing.

- Power Generation: In biomass power plants, where organic waste is converted into electricity through combustion or gasification processes.

- Heat Treatment Processes: Used in industries such as metalworking, where controlled heating is required.

Form in which Coriander Stalks are Used in Industries

Coriander stalks can be utilized in different forms, depending on the specific industrial requirements:

- Chips and Pellets: The stalks are often processed into chips or pellets, making them easier to handle and burn in industrial equipment. This form is particularly useful for boilers and industrial furnaces, ensuring a consistent feedstock.

- Loose Biomass: Some industries may use loose coriander stalks, especially in smaller setups where pelletization may not be economically viable.

- Powdered Form: In certain applications, coriander stalks can be ground into a powder to enhance combustion efficiency and heat transfer..

Amount of Coriander Stalk Being Used by Industries for Industrial Heating

While specific data on the total amount of coriander stalks used in Indian industries is scarce, estimates suggest that approximately 15% of the coriander plant is composed of stalks. Considering India’s annual coriander production, which averages around 7 lakh tons, this translates to around 1.05 lakh tons of coriander stalks available annually for industrial use.

Furthermore, as industries are increasingly focusing on sustainable practices, the usage of coriander stalks is expected to rise. Initiatives promoting biomass energy have led to a surge in demand, with industries gradually shifting from traditional fossil fuels to biomass-based energy solutions.

Prominent Industries Using Coriander Stalk for Industrial Heating

Several key industries in India have recognized the benefits of utilizing coriander stalks:

- Textiles: Major textile hubs in states like Gujarat and Maharashtra are adopting biomass heating solutions.

- Food and Beverage: Companies involved in processing and packaging food products are implementing coriander stalk-based heating systems to enhance energy efficiency.

- Pharmaceuticals: The pharmaceutical industry, with its high energy demands, is exploring sustainable biomass options, including coriander stalks, to meet its heating needs.

- Agriculture: Farmers and agricultural cooperatives are also leveraging this biomass resource to fuel local heating systems for drying crops and processing produce.