Key Questions Answered in this Section

- What types of materials make up lignocellulosic biomass for CBG production?

- What components in lignocellulosic biomass resist microbial digestion?

- What are the four categories of pretreatment methods described for CBG production?

- What specific techniques are used in physical pretreatment to reduce biomass particle size?

- What temperature range is used in microwave-assisted pretreatment for biomass?

- What does hydrothermal pretreatment target in the lignocellulosic structure?

- What chemical agents are used in acid treatment to hydrolyze hemicellulose?

- What bases are employed in alkali treatment to solubilize lignin?

- What ionic liquid is mentioned for dissolving lignocellulosic components?

- What is the temperature range for steam explosion in physicochemical pretreatment?

- What catalyst is used in ammonium fiber explosion (AFEX) pretreatment?

- What enzymes are involved in enzymatic hydrolysis for CBG production?

- What specific combined pretreatment method involves steam explosion and alkali treatment?

- What steps are included in the ionic liquid pretreatment process?

- What by-products are produced during acid treatment with enzymatic hydrolysis?

- What Indian companies are mentioned for their contributions to CBG production?

Table of Contents

- Introduction

- Pretreatment Methods

- Physical Pretreatment

- Chemical Pretreatment

- Physicochemical Pretreatment

- Biological Pretreatment

- Analysis of Pretreatment Methods: Single and Combined Approaches for CBG Production

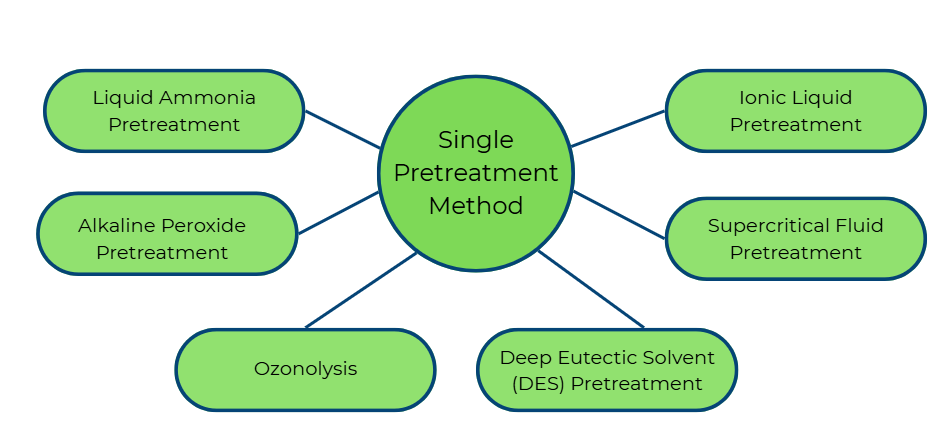

- Single Pretreatment Methods

- Combined Pretreatment Methods

- Summary Table of Combined Pretreatment Methods for CBG Production

- Highlights

- Conclusion

As the world races to combat climate change and secure sustainable energy, lignocellulosic biomass—abundant in agricultural residues, forestry byproducts, energy crops, and municipal solid waste—emerges as a cornerstone for producing bioethanol and compressed biogas (CBG). Unlike traditional feedstocks like corn or sugarcane, this renewable resource doesn’t compete with food production, offering an environmentally and economically viable path to biofuels. However, its complex structure, made up of cellulose, hemicellulose, and lignin, forms a recalcitrant barrier that resists breakdown, making efficient conversion into fermentable sugars or biogas a challenge. Pretreatment is the critical first step, disrupting lignin, reducing cellulose crystallinity, and increasing biomass porosity. This blog dives into the diverse world of pretreatment methods—physical, chemical, physicochemical, and biological—exploring their mechanisms, applications, and the power of combined approaches.

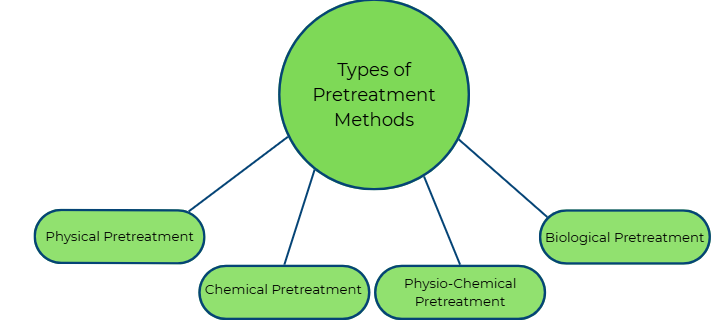

Types of Pretreatment Methods

To unlock the full potential of lignocellulosic biomass for compressed biogas (CBG) production, pretreatment is essential. The complex structure of cellulose, hemicellulose, and lignin in biomass resists microbial digestion, necessitating innovative methods to enhance accessibility and digestibility. These pretreatment techniques—categorized into physical, chemical, physicochemical, and biological approaches—disrupt the biomass matrix, increasing porosity, reducing crystallinity, and exposing fermentable sugars for anaerobic digestion. Below, we explore each method in detail, highlighting their processes, purposes, and contributions to efficient CBG production.

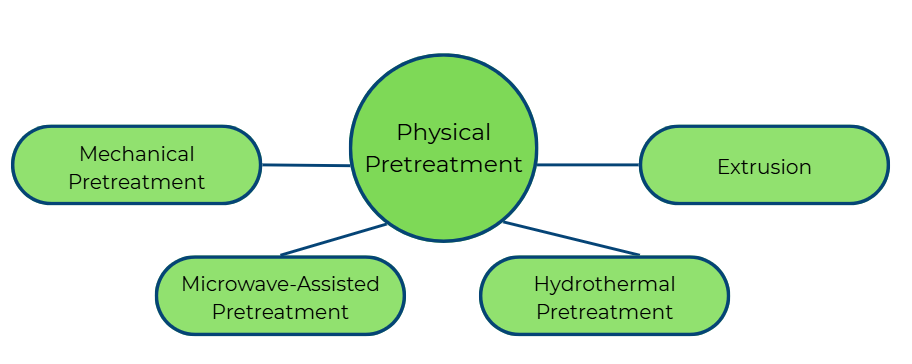

1. Physical Pretreatment

Physical pretreatment methods use mechanical or energetic processes to reduce particle size and increase surface area, making lignocellulosic biomass more accessible for microbial digestion. These techniques are often the first step in enhancing the efficiency of subsequent treatments.

1.1. Mechanical Pretreatment

Mechanical pretreatment employs milling, grinding, or extrusion to break biomass into smaller particles, boosting surface area for microbial action.

- Process: Mechanical size reduction using milling, grinding, or extrusion.

- Purpose: Reduce particle size and increase surface area.

- Temperature: Ambient to slightly elevated.

- Catalyst: None required.

1.2. Microwave-Assisted Pretreatment

Microwave-assisted pretreatment uses rapid heating to disrupt the lignocellulosic structure, improving cellulose accessibility.

- Process: Biomass is heated with microwave radiation.

- Purpose: Disrupt lignocellulosic structure.

- Temperature: 150-200°C.

- Catalyst: Water or chemical additives (e.g., dilute acid or alkali).

1.3. Hydrothermal Pretreatment

Hydrothermal pretreatment uses hot compressed water to solubilize hemicellulose and disrupt lignin, enhancing cellulose digestibility.

- Process: Treatment with hot compressed water.

- Purpose: Solubilize hemicellulose and disrupt lignin.

- Temperature: 180-240°C.

- Catalyst: None required.

1.4. Extrusion

Extrusion applies mechanical shear and compressive forces to disrupt the lignocellulosic structure.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

- Process: Biomass is processed through an extruder under elevated temperature and pressure.

- Purpose: Disrupt lignocellulosic structure.

- Temperature: 80-180°C.

- Catalyst: None required.

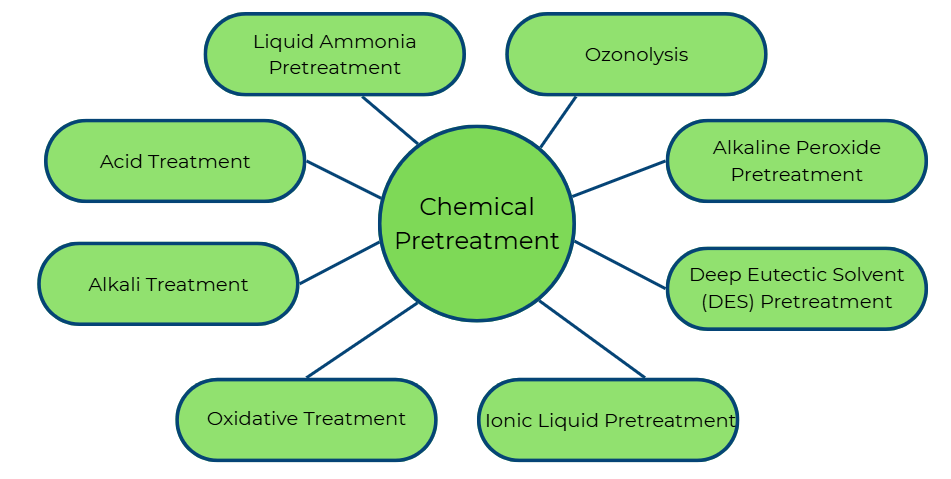

2. Chemical Pretreatment

Chemical pretreatment methods use reagents to break down lignin and hemicellulose, exposing cellulose for microbial digestion. These methods are critical for enhancing biogas yields in CBG production.

2.1. Acid Treatment

Acid treatment hydrolyzes hemicellulose and partially degrades lignin, making cellulose more accessible.

- Process: Treatment with dilute or concentrated acids (e.g., sulfuric acid).

- Purpose: Hydrolyze hemicellulose and partially degrade lignin.

- Temperature: 100-200°C.

- Catalyst: Dilute or concentrated acids (e.g., sulfuric acid).

2.2. Alkali Treatment

Alkali treatment solubilizes lignin and partially hydrolyzes hemicellulose, improving cellulose digestibility.

- Process: Treatment with alkaline solutions (e.g., sodium hydroxide, lime).

- Purpose: Solubilize lignin and improve cellulose digestibility.

- Temperature: 50-130°C.

- Catalyst: Bases (e.g., sodium hydroxide, lime)

2.3. Oxidative Treatment

Oxidative treatment degrades lignin and hemicellulose, enhancing cellulose accessibility.

- Process: Treatment with oxidizing agents (e.g., hydrogen peroxide, ozone).

- Purpose: Break down lignin and hemicellulose.

- Temperature: 25-80°C.

- Catalyst: Oxidizing agents (e.g., hydrogen peroxide, ozone)

2.4. Ionic Liquid Pretreatment

Ionic liquid pretreatment dissolves lignin and hemicellulose, leaving a cellulose-rich residue.

- Process: Treatment with ionic liquids (e.g., 1-ethyl-3-methylimidazolium acetate).

- Purpose: Dissolve lignin and hemicellulose.

- Temperature: 60-120°C.

- Catalyst: Ionic liquids.

2.5. Deep Eutectic Solvent (DES) Pretreatment

DES pretreatment solubilizes lignin and hemicellulose, improving cellulose accessibility.

- Process: Treatment with deep eutectic solvents (e.g., choline chloride and urea).

- Purpose: Solubilize lignin and hemicellulose.

- Temperature: 60-120°C.

- Catalyst: DES (e.g., choline chloride and urea).

2.6. Alkaline Peroxide Pretreatment

Alkaline peroxide pretreatment delignifies and breaks down hemicellulose, enhancing cellulose accessibility.

- Process: Treatment with alkaline hydrogen peroxide (e.g., sodium hydroxide and hydrogen peroxide).

- Purpose: Delignify and break down hemicellulose.

- Temperature: 30-80°C.

- Catalyst: Alkaline solution and hydrogen peroxide.

2.7. Ozonolysis

Ozonolysis degrades lignin and hemicellulose, enhancing cellulose accessibility.

- Process: Treatment with ozone gas.

- Purpose: Degrade lignin and hemicellulose.

- Temperature: Ambient.

- Catalyst: Ozone (O3).

2.8. Liquid Ammonia Pretreatment

Liquid ammonia pretreatment disrupts lignin and hemicellulose, improving cellulose digestibility.

- Process: Treatment with liquid ammonia.

- Purpose: Disrupt lignin and hemicellulose structure.

- Temperature: 60-100°C.

- Catalyst: Liquid ammonia.

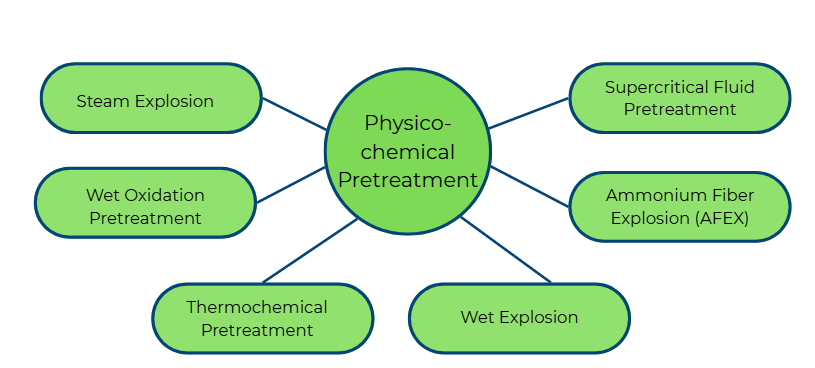

3. Physicochemical Pretreatment

Physicochemical pretreatment methods blend physical and chemical processes to disrupt the lignocellulosic matrix, increasing porosity and reactivity for improved biogas yields.

3.1. Steam Explosion

Steam explosion uses high-pressure steam and rapid decompression to disrupt lignin and enhance cellulose accessibility.

- Process: Rapid heating with high-pressure steam, followed by explosive decompression.

- Purpose: Disrupt lignin structure and increase cellulose accessibility.

- Temperature: 160-240°C.

- Catalyst: Sometimes combined with acid catalysts.

3.2. Wet Oxidation Pretreatment

Wet oxidation uses water and oxygen under high pressure to break down lignin and hemicellulose.

- Process: Treatment with water and oxygen or air under elevated temperature and pressure.

- Purpose: Break down lignin and hemicellulose.

- Temperature: 150-200°C.

- Catalyst: Oxygen or air.

3.3. Supercritical Fluid Pretreatment

Supercritical fluid pretreatment uses fluids like CO2 to disrupt the lignocellulosic structure.

- Process: Treatment with supercritical fluids (e.g., CO2).

- Purpose: Enhance cellulose accessibility.

- Temperature: Varies (e.g., 31°C for supercritical CO2).

- Catalyst: None required.

3.4. Thermochemical Pretreatment

Thermochemical pretreatment combines thermal and chemical treatments to break down lignin and hemicellulose.

- Process: Combination of thermal and chemical treatment with acids or alkalis.

- Purpose: Break down lignin and hemicellulose.

- Temperature: 120-220°C.

- Catalyst: Acids or alkalis (e.g., sulfuric acid, sodium hydroxide).

3.5. Wet Explosion

Wet explosion uses water under high pressure and rapid decompression to disrupt the lignocellulosic structure.

- Process: Rapid heating with water under high pressure, followed by explosive decompression.

- Purpose: Disrupt lignocellulosic structure.

- Temperature: 180-230°C.

- Catalyst: Water.

3.6. Ammonium Fiber Explosion (AFEX)

AFEX uses anhydrous ammonia and rapid pressure release to disrupt lignin and hemicellulose.

- Process: Treatment with anhydrous ammonia under high pressure, followed by rapid pressure release.

- Purpose: Disrupt lignin and hemicellulose structure.

- Temperature: 60-100°C.

- Catalyst: Anhydrous ammonia.

4. Biological Pretreatment

Biological pretreatment methods use microorganisms and enzymes to degrade lignocellulosic biomass, offering eco-friendly, low-energy solutions for CBG production.

4.1. Enzymatic Hydrolysis

Enzymatic hydrolysis breaks down cellulose and hemicellulose into fermentable sugars.

- Process: Hydrolysis with specific enzymes like cellulases and hemicellulases.

- Purpose: Break down cellulose and hemicellulose into fermentable sugars.

- Temperature: 45-50°C.

- Catalyst: Enzymes (e.g., cellulases, hemicellulases).

4.2. Microbial Treatment

Microbial treatment uses lignin-degrading microorganisms to improve cellulose and hemicellulose availability.

- Process: Treatment with lignin-degrading microorganisms (e.g., white-rot fungi).

- Purpose: Degrade lignin and improve cellulose and hemicellulose accessibility.

- Temperature: Ambient to slightly elevated.

- Catalyst: Microorganisms (e.g., white-rot fungi).

Analysis of Pretreatment Methods: Single and Combined Approaches for CBG Production

Pretreatment is the cornerstone of transforming lignocellulosic biomass into compressed biogas (CBG), breaking down its tough matrix of cellulose, hemicellulose, and lignin to make cellulose accessible for microbial digestion. There are two main approaches: single pretreatment methods, which use one technique to alter the biomass structure, and combined pretreatment methods, which integrate multiple techniques for enhanced efficiency and sugar yields. In this section, we dive into the mechanisms, steps, and effectiveness of both approaches, exploring how they unlock the potential of lignocellulosic biomass for sustainable CBG production.

1. Single Pretreatment Methods

Single pretreatment methods target specific components of lignocellulosic biomass, offering straightforward yet effective ways to enhance digestibility. Below, we explore key single pretreatment techniques, their processes, and their roles in CBG production.

1.1. Ionic Liquid Pretreatment

Ionic liquid pretreatment uses specialized solvents to dissolve lignocellulosic components, leaving a cellulose-rich residue that’s easier for microbes to digest.

- Description: Ionic liquids dissolve cellulose, hemicellulose, and lignin, enhancing cellulose accessibility.

- Temperature: 60-120°C.

- Catalyst: Ionic liquids (e.g., 1-ethyl-3-methylimidazolium acetate).

- Steps:

- Preparation: Biomass is washed, dried, and ground into small particles.

- Ionic-Liquid Addition: Biomass is treated with ionic liquids in a reactor.

- Heating: The reactor is heated to 60-120°C for 1-24 hours.

- Separation: Solid (pretreated biomass) and liquid fractions are separated.

- Washing: The solid fraction is washed to remove residual ionic liquid.

- Drying: Pretreated biomass is dried to the desired moisture content.

- Why It Matters: This method is highly effective but costly due to the price of ionic liquids, making it a promising yet developing technology.

1.2. Deep Eutectic Solvent (DES) Pretreatment

DES pretreatment employs eco-friendly solvents to break down lignin and hemicellulose, boosting cellulose accessibility.

- Description: DES dissolves lignocellulosic components, improving cellulose digestibility.

- Temperature: 60-120°C.

- Catalyst: DES (e.g., choline chloride and urea).

- Steps:

- Preparation: Biomass is washed, dried, and ground into small particles.

- DES Addition: DES is prepared and added to the reactor with biomass.

- Heating: The reactor is heated to 60-120°C for 1-24 hours.

- Separation: Solid (pretreated biomass) and liquid fractions are separated.

- Washing: The solid fraction is washed to remove residual DES.

- Drying: Pretreated biomass is dried to the desired moisture content.

- Why It Matters: DES is a greener alternative to ionic liquids, but cost and scalability remain challenges.

1.3. Supercritical Fluid Pretreatment

Supercritical fluid pretreatment uses fluids like CO2 under critical conditions to disrupt the lignocellulosic structure.

- Description: Supercritical fluids (e.g., CO2) enhance cellulose accessibility without harsh chemicals.

- Temperature: Varies (e.g., 31°C for supercritical CO2).

- Catalyst: None required.

- Steps:

- Preparation: Biomass is washed, dried, and ground into small particles.

- Supercritical-Fluid Addition: Supercritical CO2 is added to the reactor.

- Heating & Pressurization: The reactor is heated to critical temperature and pressurized.

- Reaction Time: The reactor is maintained for 10-60 minutes.

- Depressurization: Pressure is slowly released.

- Separation: Solid (pretreated biomass) and liquid fractions are separated.

- Washing: The solid fraction is washed to remove residual fluid.

- Why It Matters: This mild, chemical-free method is eco-friendly but requires specialized equipment.

1.4. Ozonolysis

Ozonolysis uses ozone gas to degrade lignin and hemicellulose, making cellulose more accessible.

- Description: Ozone breaks down lignin and hemicellulose, enhancing cellulose digestibility.

- Temperature: Ambient.

- Catalyst: Ozone (O3).

- Steps:

- Preparation: Biomass is washed, dried, and ground into small particles.

- Ozone Generation: Ozone gas is produced using an ozone generator.

- Ozone Addition: Ozone is introduced into the reactor with biomass.

- Reaction Time: The reactor is maintained at ambient temperature for 30 minutes to several hours.

- Ventilation: The reactor is ventilated to remove residual ozone.

- Separation: Solid (pretreated biomass) and liquid fractions are separated.

- Washing: The solid fraction is washed to remove residual chemicals.

- Drying: Pretreated biomass is dried to the desired moisture content.

- Why It Matters: Ozonolysis is effective and operates at ambient conditions, but ozone generation can be costly.

1.5. Alkaline Peroxide Pretreatment

Alkaline peroxide pretreatment combines alkali and hydrogen peroxide to delignify biomass and break down hemicellulose.

- Description: The combination of alkaline solution and hydrogen peroxide enhances cellulose accessibility.

- Temperature: 30-80°C.

- Catalyst: Alkaline solution (e.g., sodium hydroxide) and hydrogen peroxide.

- Steps:

- Preparation: Biomass is washed, dried, and ground into small particles.

- Alkaline Peroxide Addition: Alkaline solution and hydrogen peroxide are added to the reactor with biomass.

- Mixing: Biomass is thoroughly mixed with the solution.

- Heating: The reactor is heated to 30-80°C.

- Reaction Time: The reactor is maintained for 1-24 hours.

- Separation: Solid (pretreated biomass) and liquid fractions are separated.

- Why It Matters: This method is environmentally friendly but involves costs for reagents.

1.6. Liquid Ammonia Pretreatment

Liquid ammonia pretreatment disrupts lignin and hemicellulose, improving cellulose accessibility.

- Description: Liquid ammonia breaks down lignocellulosic structures for better microbial digestion.

- Temperature: 60-100°C.

- Catalyst: Liquid ammonia.

- Steps:

- Preparation: Biomass is washed, dried, and ground into small particles.

- Ammonia Addition: Liquid ammonia is added to the reactor with biomass.

- Heating & Pressurization: The reactor is heated to 60-100°C and pressurized.

- Reaction Time: The reactor is maintained for 1-3 hours.

- Depressurization: Pressure is slowly released to allow ammonia evaporation.

- Ammonia Recovery: Evaporated ammonia is captured and condensed for reuse.

- Separation: Solid (pretreated biomass) and liquid fractions are separated.

- Washing: The solid fraction is washed to remove residual ammonia.

- Drying: Pretreated biomass is dried to the desired moisture content.

- Why It Matters: Ammonia recovery makes this method economically attractive, though initial costs are high.

2. Combined Pretreatment Methods:

While single pretreatment methods are effective, combining techniques can overcome their individual limitations, boosting efficiency and sugar yields for CBG production. Below, we explore key combined pretreatment methods, their rationales, steps, and impacts

- Steam Explosion + Alkali Treatment

- Acid Treatment + Enzymatic Hydrolysis

- Alkali Treatment + Enzymatic Hydrolysis

- Oxidative Treatment + Steam Explosion

- Ionic Liquid Pretreatment + Enzymatic Hydrolysis

- Liquid Hot Water (LHW) Treatment + Enzymatic Hydrolysis

- Microwave-Assisted Pretreatment + Alkali Treatment

- Wet Oxidation Pretreatment + Enzymatic Hydrolysis

- Deep Eutectic Solvent (DES) Pretreatment + Enzymatic Hydrolysis

- Mechanical Comminution + Enzymatic Hydrolysis

- Mechanical Comminution + Alkaline Pretreatment

- Irradiation + Enzymatic Hydrolysis

2.1. Steam Explosion + Alkali Treatment

This combination leverages steam explosion’s ability to increase porosity with alkali treatment’s lignin removal.

- Reason for Combination: Steam explosion enhances biomass porosity, making alkali treatment more effective at removing lignin.

- Steps:

- Steam Explosion: Treat biomass with high-pressure steam at 160-240°C, followed by rapid decompression.

- Alkali Treatment: Soak exploded biomass in an alkaline solution (e.g., NaOH) at 50-120°C to remove lignin.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Disrupts lignocellulosic structure, removes lignin, and increases cellulose accessibility.

- By-products: Solubilized lignin, hemicellulose sugars, organic acids.

- Fate of Lignin: Partially solubilized and removed, enhancing anaerobic digestion.

2.2. Acid Treatment + Enzymatic Hydrolysis

Acid treatment breaks down hemicellulose, while enzymatic hydrolysis converts cellulose into sugars.

- Reason for Combination: Acid treatment hydrolyzes hemicellulose, and enzymatic hydrolysis targets cellulose for sugar production.

- Steps:

- Acid Treatment: Treat biomass with dilute acid (e.g., sulfuric acid) at 100-200°C to hydrolyze hemicellulose.

- Enzymatic Hydrolysis: Use cellulase enzymes to hydrolyze cellulose into glucose at 45-50°C and pH 4.8-5.0.

- Effect: Increases cellulose accessibility and produces fermentable sugars.

- By-products: Hemicellulose sugars, acetic acid, furfural, HMF.

- Fate of Lignin: Partially fragmented, remains in solid residue.

2.3. Alkali Treatment + Enzymatic Hydrolysis

Alkali treatment removes lignin, paving the way for enzymatic hydrolysis to produce sugars.

- Reason for Combination: Alkali treatment enhances cellulose accessibility by removing lignin, followed by enzymatic hydrolysis for sugar production.

- Steps:

- Alkali Treatment: Soak biomass in an alkaline solution (e.g., NaOH) at 50-120°C to remove lignin.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Removes lignin, enhances cellulose accessibility, and produces fermentable sugars.

- By-products: Solubilized lignin, hemicellulose sugars, organic acids.

- Fate of Lignin: Significantly solubilized and removed, enhancing anaerobic digestion.

2.4. Oxidative Treatment + Steam Explosion

Oxidative treatment weakens lignin, making steam explosion more effective at disrupting the biomass.

- Reason for Combination: Oxidative treatment disrupts lignin, enhancing steam explosion’s ability to remove it.

- Steps:

- Oxidative Treatment: Treat biomass with an oxidizing agent (e.g., hydrogen peroxide) at 25-80°C to oxidize lignin.

- Steam Explosion: Treat oxidized biomass with high-pressure steam at 160-240°C, followed by rapid decompression.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Oxidizes and removes lignin, increases porosity, and enhances enzyme accessibility.

- By-products: Solubilized lignin fragments, carboxylic acids, phenolic compounds.

- Fate of Lignin: Oxidized and partially removed, enhancing anaerobic digestion.

2.5. Ionic Liquid Pretreatment + Enzymatic Hydrolysis

Ionic liquids dissolve lignocellulosic components, followed by enzymatic hydrolysis for sugar production.

- Reason for Combination: Ionic liquids enhance cellulose accessibility, and enzymatic hydrolysis converts cellulose into sugars.

- Steps:

- Ionic Liquid Pretreatment: Treat biomass with ionic liquids at 60-120°C to dissolve lignocellulosic components.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Dissolves lignocellulosic components, improves cellulose accessibility, and produces fermentable sugars.

- By-products: Solubilized lignin, hemicellulose sugars.

- Fate of Lignin: Dissolved in the ionic liquid, can be separated and recovered.

2.6. Liquid Hot Water (LHW) Treatment + Enzymatic Hydrolysis

LHW treatment removes hemicellulose, followed by enzymatic hydrolysis to produce sugars.

- Reason for Combination: LHW treatment hydrolyzes hemicellulose, and enzymatic hydrolysis targets cellulose for sugar production.

- Steps:

- LHW Treatment: Treat biomass with hot water at 180-240°C to hydrolyze hemicellulose.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Hydrolyzes hemicellulose, increases cellulose accessibility, and produces fermentable sugars.

- By-products: Hemicellulose sugars, acetic acid, furfural, HMF.

- Fate of Lignin: Largely remains in solid residue, enhancing anaerobic digestion.

2.7. Microwave-Assisted Pretreatment + Alkali Treatment

Microwave heating disrupts biomass, followed by alkali treatment to remove lignin.

- Reason for Combination: Microwave pretreatment causes physical and chemical changes, enhancing alkali treatment’s lignin removal.

- Steps:

- Microwave-Assisted Pretreatment: Expose biomass to microwave energy at 150-200°C to disrupt the structure.

- Alkali Treatment: Treat disrupted biomass with an alkali solution at 50-120°C to remove lignin.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Disrupts structure, removes lignin, and increases cellulose accessibility.

- By-products: Solubilized lignin, hemicellulose sugars, organic acids.

- Fate of Lignin: Significantly solubilized and removed, enhancing anaerobic digestion.

2.8. Wet Oxidation Pretreatment + Enzymatic Hydrolysis

Wet oxidation reduces lignin content, followed by enzymatic hydrolysis for sugar production.

- Reason for Combination: Wet oxidation disrupts lignin and biomass structure, enhancing enzymatic hydrolysis efficiency.

- Steps:

- Wet Oxidation: Treat biomass with water and oxygen at 150-200°C under high pressure to oxidize lignin.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Oxidizes lignin, increases porosity, and enhances enzyme accessibility.

- By-products: Solubilized lignin fragments, carboxylic acids, phenolic compounds.

- Fate of Lignin: Partially oxidized and solubilized, enhancing anaerobic digestion.

2.9. Deep Eutectic Solvent (DES) Pretreatment + Enzymatic Hydrolysis

DES pretreatment dissolves lignocellulosic components, followed by enzymatic hydrolysis for sugar production.

- Reason for Combination: DES enhances cellulose accessibility, and enzymatic hydrolysis produces fermentable sugars.

- Steps:

- DES Pretreatment: Treat biomass with DES at 60-120°C to dissolve lignocellulosic components.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Dissolves lignocellulosic components, improves cellulose accessibility, and produces fermentable sugars.

- By-products: Solubilized lignin, hemicellulose sugars.

- Fate of Lignin: Dissolved in the DES, can be separated and recovered.

2.10. Mechanical Comminution + Enzymatic Hydrolysis

Mechanical comminution reduces particle size, followed by enzymatic hydrolysis to produce sugars.

- Reason for Combination: Mechanical comminution increases surface area, enhancing enzymatic hydrolysis efficiency.

- Steps:

- Mechanical Comminution: Reduce biomass particle size through grinding or milling.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Reduces particle size, increases surface area, and enhances enzyme accessibility.

- By-products: Minimal, mostly mechanical degradation products.

- Fate of Lignin: Remains largely unchanged, enhancing anaerobic digestion.

2.11. Mechanical Comminution + Alkaline Pretreatment

Mechanical comminution reduces particle size, followed by alkaline pretreatment to remove lignin.

- Reason for Combination: Mechanical comminution increases surface area, making alkaline pretreatment more effective at lignin removal.

- Steps:

- Mechanical Comminution: Reduce biomass particle size through grinding or milling.

- Alkaline Pretreatment: Treat comminuted biomass with an alkali solution at 50-120°C to remove lignin.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Reduces particle size, removes lignin, and increases cellulose accessibility.

- By-products: Solubilized lignin, hemicellulose sugars, organic acids.

- Fate of Lignin: Significantly solubilized and removed, enhancing anaerobic digestion.

2.12. Irradiation + Enzymatic Hydrolysis

Irradiation disrupts the lignocellulosic structure, followed by enzymatic hydrolysis for sugar production.

- Reason for Combination: Irradiation makes biomass more susceptible to enzymatic hydrolysis by disrupting its structure.

- Steps:

- Irradiation: Expose biomass to gamma or UV radiation to disrupt the structure.

- Enzymatic Hydrolysis: Subject pretreated biomass to cellulase enzymes at 45-50°C and pH 4.8-5.0.

- Effect: Disrupts structure, increases cellulose accessibility, and enhances hydrolysis efficiency.

- By-products: Hemicellulose sugars, acetic acid, furfural, HMF.

- Fate of Lignin: Partially fragmented, remains in solid residue.

Summary Table of Combined Pretreatment Methods for CBG Production

Table: Combined Pretreatment Methods Overview

| Combination | Purpose | Temp (°C) | Feedstock | By-products | Lignin Fate |

| Steam Explosion + Alkali | Increases porosity & removes lignin | Steam: 160–260 Alkali: 50–120 | Agri-residues, crops, softwoods | Solubilized lignin, hemicellulose sugars, organic acids | Partially removed |

| Acid + Enzymatic Hydrolysis | Breaks down hemicellulose & cellulose | Acid: 120–180 Enzyme: 40–50 | Hardwoods, agri-residues | Sugars, acetic acid, furfural, HMF | Remains in residue |

| Alkali + Enzymatic Hydrolysis | Removes lignin, hydrolyzes cellulose | Alkali: 50–120 Enzyme: 40–50 | Agri-residues, crops, softwoods | Solubilized lignin, hemicellulose sugars, organic acids | Significantly removed |

| Oxidative + Steam Explosion | Disrupts lignin, increases porosity | Oxidative: 80–150 Steam: 160–260 | Hardwoods, residues | Lignin fragments, carboxylic acids, phenolics | Oxidized & reduced |

| Ionic Liquid + Enzymatic | Dissolves components, sugar production | IL: 70–150 Enzyme: 40–50 | Hardwoods, residues | Solubilized lignin, hemicellulose sugars | Dissolved & recoverable |

| LHW + Enzymatic Hydrolysis | Removes hemicellulose, releases sugars | LHW: 160–240 Enzyme: 40–50 | Hardwoods, residues | Hemicellulose sugars, acetic acid, furfural, HMF | Mostly remains |

| Microwave + Alkali | Disrupts structure & removes lignin | Microwave: 100–200 Alkali: 50–120 | Crops, residues | Solubilized lignin, hemicellulose sugars, organic acids | Significantly removed |

| Wet Oxidation + Enzymatic | Oxidizes lignin, releases sugars | Wet Oxidation: 150–200 Enzyme: 40–50 | High-lignin biomass | Lignin fragments, carboxylic acids, phenolics | Oxidized & reduced |

| DES + Enzymatic Hydrolysis | Dissolves biomass, enhances hydrolysis | DES: 70–150 Enzyme: 40–50 | Hardwoods, residues | Solubilized lignin, hemicellulose sugars | Dissolved & recoverable |

| Mechanical + Enzymatic | Reduces particle size, hydrolyzes | Mechanical: Ambient Enzyme: 40–50 | Various biomass | Minimal degradation products | Largely unchanged |

| Mechanical + Alkali | Reduces size & removes lignin | Mechanical: Ambient Alkali: 50–120 | Various biomass | Solubilized lignin, hemicellulose sugars, organic acids | Significantly removed |

| Irradiation + Enzymatic | Disrupts structure, boosts hydrolysis | Irradiation: Varies Enzyme: 40–50 | Various biomass | Sugars, acetic acid, furfural, HMF | Partially fragmented |

Highlights

- Challenges in Biomass Structure: The complex structure of lignocellulosic biomass, composed of cellulose, hemicellulose, and lignin, poses significant challenges for efficient biogas conversion.

- Physical Pre-treatment Efficiency: Mechanical comminution, microwave-assisted pretreatment, hydrothermal pretreatment, and extrusion effectively reduce particle size and increase surface area, enhancing biomass digestibility.

- Chemical Pre-treatment Techniques: Acid, alkali, and oxidative treatments, along with ionic liquids and deep eutectic solvents (DES), hydrolyze hemicellulose, solubilize lignin, and improve cellulose accessibility.

- Physicochemical Methods: Steam explosion, wet oxidation, supercritical fluid treatment, and thermochemical pretreatment combine physical and chemical.

- Biological Approaches: Enzymatic hydrolysis and microbial treatments leverage natural enzymes and microorganisms to break down cellulose and hemicellulose into fermentable sugars.

- Combined Pre-treatment Strategies: Methods like steam explosion with alkali treatment and acid treatment with enzymatic hydrolysis are highlighted for their synergistic effects, maximizing biomass digestibility.

- Cost-Effectiveness: Certain pre-treatment methods, such as mechanical comminution and alkali treatments, offer cost-effective solutions due to their relatively low operational costs and minimal energy requirements.

- Process Optimization: The report emphasizes the importance of optimizing pre-treatment conditions, including temperature, pressure, and chemical concentrations, to maximize the efficiency and yield of biogas production.

- Scalability and Industrial Application: The analysis provides insights into the scalability of various pre-treatment methods, highlighting those that are feasible for large-scale industrial applications, and ensuring a practical transition from laboratory to industry.

Conclusion

Effective pretreatment is the backbone of successful compressed biogas (CBG) production from lignocellulosic biomass. Because these materials are tough and complex—packed with cellulose, hemicellulose, and lignin—breaking them down efficiently is key to unlocking their energy potential. While individual methods like mechanical size reduction, chemical solubilization, or enzymatic hydrolysis offer value, it’s the combined pretreatment strategies that stand out.

By merging approaches—like steam explosion with alkali treatment or acid treatment followed by enzymatic hydrolysis—we can overcome the limitations of single methods and significantly boost biogas yield. These synergistic treatments not only enhance microbial digestion but also streamline the conversion process.

As the demand for sustainable energy grows, investing in smart pretreatment combinations will be crucial for making bio-based energy both viable and scalable. This understanding lays a strong foundation for future innovations in biofuel technologies and greener industrial practices.