Key Questions Answered in this Section

- What is lignocellulosic feedstock?

- Why is lignocellulosic biomass sustainable for ethanol?

- Why is pretreatment essential?

- Which Indian companies lead in lignocellulosic ethanol?

- What are physical pretreatment methods?

- How does mechanical comminution work?

- What are chemical pretreatment methods?

- How does acid pretreatment function?

- What are physicochemical pretreatments?

- How does steam explosion improve biomass?

- What is biological pretreatment?

- Are single or combined pretreatment methods better?

- What environmental benefits do pretreatments offer?

- What challenges exist in pretreatment?

As the world seeks sustainable energy solutions to combat climate change and reduce reliance on fossil fuels, lignocellulosic biomass—derived from abundant, renewable sources like agricultural residues, forestry byproducts, energy crops, and municipal solid waste—stands out as a game-changer for bioethanol production. Unlike traditional feedstocks such as corn or sugarcane, lignocellulosic biomass avoids competition with food crops, offering an environmentally and economically viable path to large-scale biofuel production. However, its complex structure, composed of cellulose, hemicellulose, and lignin, forms a stubborn barrier that resists breakdown, making efficient conversion to fermentable sugars a challenge. This is where pretreatment steps in as a critical process, breaking down lignin, reducing cellulose crystallinity, and increasing biomass porosity to enhance enzymatic hydrolysis and ethanol yields. Driven by the need for sustainable energy and economic viability, this blog explores the diverse pretreatment methods—physical, chemical, physicochemical, and biological—and their role in optimizing lignocellulosic ethanol production, paving the way for a cleaner, greener future.

Table of Content

- Introduction

- What is Lignocellulosic Feedstock?

- Composition of Lignocellulosic Biomass

- Current Indian Companies in Lignocellulosic Ethanol Production

- Pretreatment Methods: Background and Concepts

- Physical Pretreatment

- Chemical Pretreatment

- Physicochemical Pretreatment

- Biological Pretreatment

- Analysis of Pretreatment Methods

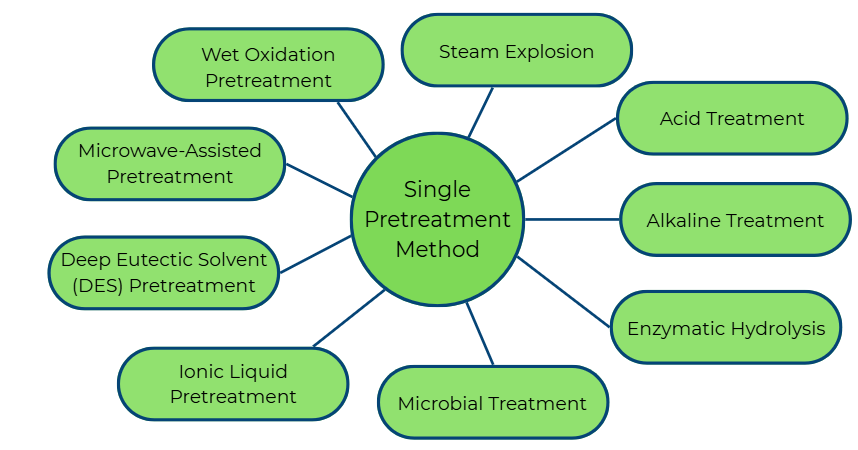

- Analysis of Single Pretreatment Method

- Analysis of Combined Pretreatment Methods

- Highlights

- Conclusion

What is Lignocellulosic Feedstock?

Lignocellulosic feedstock refers to plant biomass that is composed mainly of cellulose, hemicellulose, and lignin. It includes a variety of agricultural residues (such as straw and corn stover), forestry residues (such as wood chips and sawdust), energy crops (like switchgrass and miscanthus), and even municipal solid waste. The high availability and renewability of lignocellulosic biomass make it a promising raw material for the sustainable production of bioethanol, a renewable alternative to fossil fuels.

1.Composition of Lignocellulosic Biomass

- Cellulose: A polysaccharide consisting of linear chains of glucose units. It forms the structural component of plant cell walls.

- Hemicellulose: A heterogeneous polysaccharide made up of various sugar monomers. It is more easily hydrolyzed compared to cellulose.

- Lignin: A complex aromatic polymer that provides rigidity and resistance to microbial attack. It acts as a barrier to the enzymatic breakdown of cellulose and hemicellulose.

2.Current Indian Companies in Lignocellulosic Ethanol Production

Several companies in India are actively involved in the production of bioethanol from lignocellulosic biomass. Here are a few notable ones:

- Praj Industries

- Description: Praj Industries is a leading Indian company specializing in bio-based technologies and engineering. They offer integrated solutions for the production of bioethanol from lignocellulosic biomass.

- Technologies: They have developed proprietary technologies for pretreatment, enzymatic hydrolysis, and fermentation processes.

- Projects: Praj Industries has set up multiple pilot and commercial-scale lignocellulosic ethanol plants across India.

- Hindustan Petroleum Corporation Limited (HPCL)

- Description: HPCL is another significant public sector oil and gas company involved in bioethanol production.

- Projects: HPCL is setting up lignocellulosic ethanol plants as part of their strategy to integrate biofuels into their energy portfolio.

- BPCL Biofuels

- Description: Bharat Petroleum Corporation Limited (BPCL) has ventured into the biofuels sector with a focus on lignocellulosic ethanol.

- Projects: BPCL has established lignocellulosic ethanol production units utilizing agricultural residues.

Pretreatment Methods: Background and Concepts

1. Physical Pretreatment

Physical pretreatment methods focus on reducing particle size and increasing surface area to prepare lignocellulosic biomass for further processing. These techniques set the stage for chemical or enzymatic treatments.

1.1 Mechanical Comminution

Mechanical comminution uses mechanical force to break biomass into smaller particles, enhancing accessibility by increasing surface area and reducing cellulose crystallinity.

- Process: Milling, grinding, or chipping biomass with equipment like hammer mills, ball mills, or chippers.

- Purpose: Increase surface area and reduce cellulose crystallinity to improve enzymatic access.

- Equipment: Hammer mills, ball mills, chippers.

- Temperature: Ambient to slightly elevated, depending on the method.

- Catalyst: None required.

- Description: This energy-intensive process significantly boosts the efficiency of subsequent treatments by making biomass more amenable to processing, though high energy costs are a challenge.

1.2 Irradiation

Irradiation employs gamma rays, electron beams, or microwaves to disrupt cellulose’s crystalline structure and break down lignin, enhancing biomass digestibility.

- Process: Exposing biomass to gamma rays, electron beams, or microwaves.

- Purpose: Disrupt cellulose structure and degrade lignin for better enzyme access.

- Temperature: Varies based on the irradiation method.

- Catalyst: None required.

- Description: By altering physical and chemical properties, irradiation improves digestibility. It’s a promising method but remains under research due to high costs and complexity.

2. Chemical Pretreatment

Chemical pretreatment methods use reagents to break down lignin and hemicellulose, exposing cellulose for enzymatic hydrolysis. These methods are powerful but require careful chemical management.

2.1 Acid Pretreatment

Acid pretreatment uses dilute or concentrated acids to hydrolyze hemicellulose and disrupt lignin, making cellulose more accessible.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

- Process: Treating biomass with acids like sulfuric or hydrochloric acid.

- Purpose: Hydrolyze hemicellulose into fermentable sugars and disrupt lignin.

- Temperature: 120-200°C.

- Catalyst: Sulfuric acid (1-10% concentration) or hydrochloric acid.

- Description: Highly effective, this method breaks down hemicellulose and lignin but requires neutralization due to acid corrosiveness. Dilute acid uses higher temperatures, while concentrated acid operates at lower temperatures.

2.2 Alkaline Pretreatment

Alkaline pretreatment employs solutions like sodium or calcium hydroxide to solubilize lignin and some hemicellulose, improving cellulose digestibility.

- Process: Treating biomass with alkaline solutions.

- Purpose: Solubilize lignin and hemicellulose to enhance cellulose access.

- Temperature: 60-120°C.

- Catalyst: Sodium hydroxide or calcium hydroxide (1-10% concentration).

- Description: Less harsh than acid pretreatment, this method effectively removes lignin at lower temperatures but may result in some hemicellulose loss.

2.3 Organosolv Pretreatment

Organosolv pretreatment uses organic solvents like ethanol or acetone to dissolve lignin and hemicellulose, yielding a cellulose-rich residue.

- Process: Treating biomass with organic solvents, with or without acid/alkaline catalysts.

- Purpose: Solubilize lignin and hemicellulose, producing high-purity cellulose.

- Temperature: 150-200°C.

- Catalyst: Optional acid or alkaline catalysts.

- Description: This method produces valuable lignin byproducts and high-purity cellulose, but solvent recovery adds cost and complexity.

2.4 Oxidative Pretreatment

Oxidative pretreatment uses oxidizing agents like hydrogen peroxide or ozone to break down lignin and disrupt cellulose structure.

- Process: Treating biomass with oxidizing agents.

- Purpose: Oxidize lignin and disrupt cellulose for better enzyme access.

- Temperature: 20-60°C.

- Catalyst: Hydrogen peroxide or ozone.

- Description: Environmentally friendly and effective at low temperatures, this method enhances hydrolysis but is costly due to expensive oxidizing agents.

3. Physicochemical Pretreatment

Physicochemical pretreatment combines physical and chemical approaches to efficiently break down the lignocellulosic structure, balancing impact and cost.

3.1 Steam Explosion

Steam explosion uses high-pressure steam and rapid decompression to disrupt lignin and increase cellulose accessibility.

- Process: Heating biomass with high-pressure steam, followed by explosive decompression.

- Purpose: Disrupt lignin and increase cellulose accessibility.

- Temperature: 160-240°C.

- Catalyst: Optional sulfuric acid.

- Description: Widely used for its efficiency and moderate cost, this method boosts porosity but may produce inhibitory compounds.

3.2 Ammonia Fiber Expansion (AFEX)

AFEX treats biomass with liquid ammonia under high pressure, followed by rapid pressure release, to disrupt lignin and hemicellulose.

- Process: Treating biomass with liquid ammonia, followed by rapid depressurization.

- Purpose: Disrupt lignin and hemicellulose, increasing digestibility.

- Temperature: 60-100°C.

- Catalyst: Liquid ammonia.

- Description: Economically attractive due to ammonia recovery and no inhibitory byproducts, though the high cost of ammonia is a consideration.

3.3 CO2 Explosion

CO2 explosion uses supercritical CO2 and rapid depressurization to enhance cellulose accessibility without harsh chemicals.

- Process: Treating biomass with supercritical CO2, followed by rapid depressurization.

- Purpose: Disrupt lignocellulosic structure to increase cellulose accessibility.

- Temperature: Around 31°C (supercritical CO2 conditions).

- Catalyst: None required.

- Description: This mild method avoids harsh chemicals but requires specialized equipment for handling supercritical CO2.

4. Biological Pretreatment

Biological pretreatment leverages microorganisms to degrade lignin and hemicellulose, offering a sustainable, low-energy approach.

4.1 Microbial Treatment

Microbial treatment uses fungi or bacteria to selectively degrade lignin while preserving cellulose.

- Process: Inoculating biomass with lignin-degrading microorganisms like white-rot fungi.

- Purpose: Selectively degrade lignin, preserving cellulose for hydrolysis.

- Temperature: Ambient to slightly elevated.

- Catalyst: Microorganisms such as white-rot fungi.

- Description: Environmentally friendly and low-energy, this method is time-consuming, often taking weeks, and is best combined with other pretreatments for efficiency.

Analysis of Pretreatment Methods

Pretreatment is a crucial step in the conversion of lignocellulosic biomass into bioethanol, aimed at breaking down the complex structure of plant biomass to make cellulose more accessible for enzymatic hydrolysis. There are two main types of pretreatment methods:

- Single Pretreatment Method

- Combined Pretreatment Method

Single pretreatment methods, such as acid or steam explosion, focus on one approach to alter the biomass structure, while combined methods integrate multiple techniques to enhance efficiency and sugar yields. This analysis will explore both single and combined pretreatment methods, examining their mechanisms, applications, and effectiveness in bioethanol production.

1. Analysis of Single Pretreatment Method

Converting lignocellulosic biomass—think crop residues, wood chips, or energy crops—into bioethanol is a promising path to sustainable energy, but its complex structure of cellulose, hemicellulose, and lignin makes it tough to process. Pretreatment is the key to unlocking this potential, breaking down the biomass to make cellulose accessible for enzymatic hydrolysis and fermentable sugar production. In this section, we dive into single pretreatment methods, exploring how techniques like steam explosion, acid treatment, and others work to transform stubborn biomass into a biofuel-friendly resource. Each method has unique steps and benefits, paving the way for efficient ethanol production.

1.1. Steam Explosion

Steam explosion is a powerhouse in pretreatment, using high-pressure steam to disrupt the lignocellulosic matrix. By rapidly heating biomass and then releasing the pressure, it creates a porous structure that makes cellulose more accessible for enzymes.

How It Works:

- Heating: Biomass is blasted with high-pressure steam at 160-240°C, softening the tough lignocellulosic structure.

- Explosive Decompression: The pressure is suddenly released, causing the biomass to “explode” and become more porous.

- Cooling: The treated biomass is cooled and collected for further processing.

This method boosts surface area and porosity, making it a go-to for industrial applications, though it can produce some inhibitory byproducts.

1.2. Acid Treatment

Acid treatment uses dilute or concentrated acids to hydrolyze hemicellulose and disrupt lignin, reducing cellulose crystallinity and preparing the biomass for enzymatic hydrolysis.

How It Works:

- Acid Application: Biomass is treated with acids like sulfuric or hydrochloric at 120-200°C.

- Hydrolysis: Hemicellulose breaks down into monomeric sugars, and lignin is partially solubilized.

- Neutralization: The acidic slurry is neutralized to protect sugars from further degradation.

This method is highly effective but requires careful handling due to the corrosive nature of acids.

1.3. Alkaline Treatment

Alkaline treatment employs solutions like sodium or calcium hydroxide to solubilize lignin and some hemicellulose, enhancing cellulose digestibility in a less harsh process compared to acid treatment.

How It Works:

- Alkaline Application: Biomass is soaked in an alkaline solution at 60-120°C.

- Soaking: The process lasts from hours to days, depending on the alkali used.

- Washing: Residual alkali and solubilized lignin are washed away.

This method is effective and milder but may result in some hemicellulose loss.

1.4. Enzymatic Hydrolysis

Enzymatic hydrolysis uses specialized enzymes to break down cellulose and hemicellulose into fermentable sugars, a critical step following pretreatment.

How It Works:

- Enzyme Addition: Cellulases and hemicellulases are added to pretreated biomass.

- Hydrolysis Conditions: The mixture is incubated at 45-50°C and pH 4.8-5.0 for 24-72 hours.

- Monitoring: Sugar release is tracked to gauge hydrolysis progress.

This method is precise but depends on effective pretreatment to maximize sugar yields.

1.5. Microbial Treatment

Microbial treatment harnesses lignin-degrading microorganisms, like white-rot fungi, to selectively break down lignin, increasing cellulose accessibility.

How It Works:

- Inoculation: Biomass is inoculated with microorganisms like white-rot fungi.

- Incubation: The biomass is incubated under controlled conditions for weeks.

- Monitoring: Lignin degradation is regularly checked.

This eco-friendly method is slow but ideal when combined with other pretreatments.

1.6. Ionic Liquid Pretreatment

Ionic liquid pretreatment uses specialized liquids to dissolve lignocellulosic components, leaving a cellulose-rich residue for enzymatic hydrolysis.

How It Works:

- Ionic Liquid Application: Biomass is treated with ionic liquids at 60-120°C.

- Dissolution: Lignin and hemicellulose dissolve, isolating cellulose.

- Washing: The solid fraction is washed to remove residual ionic liquid.

This method is promising but costly due to the price of ionic liquids.

1.7. Deep Eutectic Solvent (DES) Pretreatment

Deep eutectic solvents (DES) dissolve lignin and hemicellulose, producing a cellulose-rich residue in an environmentally friendly process.

How It Works:

- DES Application: Biomass is treated with DES at 60-120°C.

- Dissolution: Lignin and hemicellulose are dissolved, leaving cellulose behind.

- Washing: Residual DES is washed from the solid fraction.

DES is a greener option but shares similar cost challenges as ionic liquids.

1.8. Microwave-Assisted Pretreatment

Microwave-assisted pretreatment uses microwave radiation to rapidly heat biomass, causing physical and chemical changes that disrupt its structure.

How It Works:

- Microwave Heating: Biomass is heated at 150-200°C using microwave radiation.

- Cooling: The treated biomass is cooled to room temperature.

- Separation: Solid and liquid fractions are separated.

This method is fast but requires specialized equipment.

1.9. Wet Oxidation Pretreatment

Wet oxidation uses water and oxygen under high temperature and pressure to break down lignin and hemicellulose, enhancing enzyme accessibility.

How It Works:

- Oxidation: Biomass is treated with water and oxygen at 150-200°C and 10-20 bar.

- Cooling: The reactor is cooled to room temperature.

- Separation: Solid and liquid fractions are separated.

This method is effective but involves high-pressure equipment costs.

2. Analysis of Combined Pretreatment Methods

2.1. Steam Explosion + Acid Treatment

Combining steam explosion and acid treatment enhances hemicellulose hydrolysis and cellulose accessibility.

- Reason for Combination: Leverages steam explosion to increase biomass porosity and acid treatment to hydrolyze hemicellulose.

- Steps Involved:

- Steam Explosion: Treat biomass with high-pressure steam followed by rapid decompression.

- Acid Treatment: Treat exploded biomass with dilute acid (e.g., sulfuric acid).

- Effect: Enhances hemicellulose hydrolysis and cellulose accessibility.

- By-products: Sugars from hemicellulose, acetic acid, furfural, HMF.

- Fate of Lignin: Partially fragmented, remains in solid residue.

2.1. Steam Explosion + Alkali Treatment

Steam explosion and alkali treatment improve cellulose accessibility by increasing biomass porosity and removing lignin.

- Reason for Combination: Steam explosion increases porosity, enhancing alkali treatment’s lignin removal efficiency.

- Steps Involved:

- Steam Explosion: Treat biomass with high-pressure steam followed by rapid decompression.

- Alkali Treatment: Treat exploded biomass with alkali solution (e.g., NaOH).

- Effect: Increases cellulose accessibility.

- By-products: Solubilized lignin, hemicellulose sugars, organic acids.

- Fate of Lignin: Significantly solubilized and removed.

2.2. Alkali Treatment + Enzymatic Hydrolysis

This combination removes lignin and enhances cellulose for efficient sugar production.

- Reason for Combination: Alkali treatment removes lignin, while enzymatic hydrolysis converts cellulose to sugars.

- Steps Involved:

- Alkali Treatment: Treat biomass with alkali solution (e.g., NaOH).

- Enzymatic Hydrolysis: Use cellulase enzymes to hydrolyze cellulose into glucose.

- Effect: Removes lignin, enhances cellulose accessibility, produces fermentable sugars.

- By-products: Solubilized lignin, hemicellulose sugars, organic acids.

- Fate of Lignin: Significantly solubilized, enhancing anaerobic digestion.

2.3. Oxidative Treatment + Steam Explosion

Oxidative treatment and steam explosion disrupt lignin and increase porosity.

- Reason for Combination: Oxidative treatment disrupts lignin, aiding removal during steam explosion.

- Steps Involved:

- Oxidative Treatment: Treat biomass with an oxidizing agent (e.g., hydrogen peroxide).

- Steam Explosion: Treat oxidized biomass with high-pressure steam and rapid decompression.

- Effect: Oxidizes and removes lignin, increases porosity, enhances enzyme accessibility.

- By-products: Solubilized lignin fragments, carboxylic acids, phenolic compounds.

- Fate of Lignin: Oxidized, partially removed, enhancing anaerobic digestion.

2.4. Ionic Liquid Pretreatment + Enzymatic Hydrolysis

Ionic liquids dissolve lignocellulosic components for better enzymatic hydrolysis.

- Reason for Combination: Ionic liquids dissolve biomass components, enhancing cellulose accessibility.

- Steps Involved:

- Ionic Liquid Pretreatment: Treat biomass with ionic liquids to dissolve cellulose, hemicellulose, and lignin.

- Enzymatic Hydrolysis: Use cellulase enzymes to hydrolyze cellulose into glucose.

- Effect: Improves cellulose accessibility, produces fermentable sugars.

- By-products: Solubilized lignin, hemicellulose sugars.

- Fate of Lignin: Dissolved in ionic liquid, can be separated and recovered.

2.5. Liquid Hot Water (LHW) Treatment + Enzymatic Hydrolysis

LHW treatment removes hemicellulose, aiding enzymatic hydrolysis.

- Reason for Combination: LHW removes hemicellulose, increasing cellulose accessibility.

- Steps Involved:

- LHW Treatment: Treat biomass with hot water to hydrolyze hemicellulose.

- Enzymatic Hydrolysis: Use cellulase enzymes to hydrolyze cellulose into glucose.

- Effect: Hydrolyzes hemicellulose, increases cellulose accessibility, produces fermentable sugars.

- By-products: Hemicellulose sugars, acetic acid, furfural, HMF.

- Fate of Lignin: Remains in solid residue, enhancing anaerobic digestion.

2.6. Microwave-Assisted Pretreatment + Alkali Treatment

Microwave heating disrupts biomass, aiding alkali lignin removal.

- Reason for Combination: Microwave pretreatment disrupts biomass structure, enhancing alkali lignin removal.

- Steps Involved:

- Microwave-Assisted Pretreatment: Expose biomass to microwave energy.

- Alkali Treatment: Treat disrupted biomass with alkali solution.

- Effect: Disrupts structure, removes lignin, increases cellulose accessibility.

- By-products: Solubilized lignin, hemicellulose sugars, organic acids.

- Fate of Lignin: Significantly solubilized, enhancing anaerobic digestion.

2.7. Wet Oxidation Pretreatment + Enzymatic Hydrolysis

Wet oxidation reduces lignin, aiding enzymatic hydrolysis.

- Reason for Combination: Wet oxidation reduces lignin content, enhancing enzyme accessibility.

- Steps Involved:

- Wet Oxidation: Treat biomass with water and oxygen under high temperature/pressure.

- Enzymatic Hydrolysis: Use cellulase enzymes to hydrolyze cellulose into glucose.

- Effect: Oxidizes lignin, increases porosity, enhances enzyme accessibility.

- By-products: Solubilized lignin fragments, carboxylic acids, phenolic compounds.

- Fate of Lignin: Partially oxidized and solubilized, enhancing anaerobic digestion.

2.8. Deep Eutectic Solvent (DES) Pretreatment + Enzymatic Hydrolysis

DES dissolves lignocellulosic components, aiding enzymatic hydrolysis.

- Reason for Combination: DES dissolves biomass components, enhancing cellulose accessibility.

- Steps Involved:

- DES Pretreatment: Treat biomass with DES to dissolve cellulose, hemicellulose, and lignin.

- Enzymatic Hydrolysis: Use cellulase enzymes to hydrolyze cellulose into glucose.

- Effect: Improves cellulose accessibility, produces fermentable sugars.

- By-products: Solubilized lignin, hemicellulose sugars.

- Fate of Lignin: Dissolved in DES, can be separated and recovered.

2.9. Steam Explosion + Enzymatic Hydrolysis

Steam explosion increases porosity, aiding enzymatic hydrolysis.

- Reason for Combination: Steam explosion disrupts lignocellulosic structure, enhancing cellulose accessibility.

- Steps Involved:

- Steam Explosion: Treat biomass with high-pressure steam (160-260°C) followed by rapid decompression.

- Enzymatic Hydrolysis: Use cellulase enzymes at 45-50°C, pH 4.8-5.0.

- Effect: Increases cellulose accessibility, produces fermentable sugars.

- By-products: Hemicellulose sugars, acetic acid, minor furfural, HMF.

- Fate of Lignin: Partially fragmented, remains in solid residue.

2.10. Ammonia Fiber Explosion (AFEX) + Enzymatic Hydrolysis

AFEX disrupts lignin, aiding enzymatic hydrolysis.

- Reason for Combination: AFEX disrupts lignin and hemicellulose, enhancing cellulose accessibility.

- Steps Involved:

- AFEX Pretreatment: Treat biomass with liquid ammonia (10-20 bar, 60-100°C), rapid pressure release.

- Enzymatic Hydrolysis: Use cellulase enzymes at 45-50°C, pH 4.8-5.0.

- Effect: Increases cellulose accessibility, produces fermentable sugars.

- By-products: Solubilized hemicellulose sugars, acetic acid, minor organic acids.

- Fate of Lignin: Partially disrupted, remains in solid residue.

2.11. Organosolv Pretreatment + Enzymatic Hydrolysis

Organosolv solubilizes lignin, aiding enzymatic hydrolysis.

- Reason for Combination: Organosolv solubilizes lignin and hemicellulose, enhancing cellulose accessibility.

- Steps Involved:

- Organosolv Pretreatment: Treat biomass with organic solvents (e.g., ethanol, acetone) at 120-200°C.

- Enzymatic Hydrolysis: Use cellulase enzymes at 45-50°C, pH 4.8-5.0.

- Effect: Increases cellulose accessibility, produces fermentable sugars.

- By-products: Hemicellulose sugars, acetic acid, minor furfural, HMF.

- Fate of Lignin: Largely solubilized, partially fragmented in solid residue.

2.12. Acid Treatment + Enzymatic Hydrolysis

Acid treatment hydrolyzes hemicellulose, aiding enzymatic hydrolysis.

- Reason for Combination: Acid treatment hydrolyzes hemicellulose, enhancing cellulose accessibility.

- Steps Involved:

- Acid Treatment: Treat biomass with dilute acid (e.g., sulfuric acid).

- Enzymatic Hydrolysis: Use cellulase enzymes to hydrolyze cellulose into glucose.

- Effect: Increases cellulose accessibility, produces fermentable sugars.

- By-products: Hemicellulose sugars, acetic acid, furfural, HMF.

- Fate of Lignin: Partially fragmented, remains in solid residue.

2.13. Steam Explosion + Alkali Treatment

Steam explosion increases porosity, while alkali treatment removes lignin.

- Reason for Combination: Steam explosion increases biomass porosity and surface area, enhancing the effectiveness of alkali treatment in removing lignin.

- Steps Involved:

- Steam Explosion: Treat biomass with high-pressure steam followed by rapid decompression.

- Alkali Treatment: Treat exploded biomass with an alkali solution (e.g., NaOH) to remove lignin.

- Effect: Increases cellulose accessibility.

- By-products: Solubilized lignin, hemicellulose sugars, organic acids.

- Fate of Lignin: The combined treatment disrupts the lignocellulosic structure, removes lignin, which is initially solubilized and removed, enhancing anaerobic digestion.

Summary Table of Combined Pretreatment Methods for Ethanol Production

| Combined Pretreatment | Reason for Combination | Temperature Range | Feedstock Type | Effect | By-products | Fate of Lignin |

|---|---|---|---|---|---|---|

| Steam Explosion + Acid Treatment | Increases porosity; acid hydrolyzes hemicellulose | 160–260°C / 120–180°C | Agricultural residues, hardwoods | Disrupts structure, improves cellulose access | Hemicellulose sugars, acetic acid, furfural, HMF | Partially solubilized, remains in residue |

| Alkali Treatment + Enzymatic Hydrolysis | Removes lignin, increases enzyme efficiency | 50–120°C / 40–50°C | Agricultural residues, softwoods | Removes lignin, enhances sugar yield | Lignin, sugars, organic acids | Significantly removed, low inhibition |

| Oxidative Treatment + Steam Explosion | Oxidizes lignin, increases surface area | 80–150°C / 160–260°C | Hardwoods, agri residues | Improves porosity, enzyme access | Lignin fragments, acids, phenolics | Oxidized, partially removed |

| Ionic Liquid + Enzymatic Hydrolysis | Dissolves components, exposes cellulose | 70–150°C / 40–50°C | Hardwoods, agri residues | Dissolves lignin/hemicellulose, improves hydrolysis | Lignin, hemicellulose sugars | Dissolved, recoverable |

| LHW + Enzymatic Hydrolysis | Removes hemicellulose, opens cellulose | 160–240°C / 40–50°C | Various lignocellulosic biomass | Increases cellulose accessibility | Hemicellulose sugars, acetic acid, HMF | Mostly retained in solids |

| Microwave + Alkali | Microwaves disrupt structure; alkali removes lignin | 100–200°C / 50–120°C | Agri residues, softwoods | Enhances delignification and hydrolysis | Lignin, hemicellulose sugars | Highly solubilized, enzyme-friendly |

| Wet Oxidation + Enzymatic Hydrolysis | Reduces lignin and improves enzyme access | 150–200°C / 40–50°C | High-lignin biomass | Increased porosity and sugar release | Lignin fragments, phenolics | Partially solubilized, less inhibitory |

| DES + Enzymatic Hydrolysis | Dissolves lignocellulose, exposes cellulose | 70–150°C / 40–50°C | Various lignocellulosic biomass | Improves hydrolysis efficiency | Lignin, hemicellulose sugars | Dissolved, recoverable |

| Steam Explosion + Enzymatic Hydrolysis | Steam opens up structure for enzymes | 160–260°C / 40–50°C | Hardwoods, agri residues | Boosts sugar yields | Sugars, acetic acid, HMF | Fragmented, retained in solids |

| AFEX + Enzymatic Hydrolysis | Disrupts lignin and hemicellulose | 70–120°C / 40–50°C | Agri residues, softwoods | Improves accessibility, yield | Sugars, organic acids | Removed significantly |

| Organosolv + Enzymatic Hydrolysis | Dissolves lignin and hemicellulose | 120–200°C / 40–50°C | Agri residues, hardwoods | Better cellulose access, sugar production | Sugars, acetic acid | Solubilized, recoverable |

| Acid + Enzymatic Hydrolysis | Acid hydrolyzes hemicellulose, enzymes convert cellulose | 120–180°C / 40–50°C | Hardwoods, agri residues | Sequential hydrolysis of biomass | Sugars, acetic acid, furfural | Partially fragmented, in residue |

| Steam Explosion + Alkali Treatment | Steam opens structure, alkali removes lignin | 160–260°C / 50–120°C | Agri residues, softwoods | Enhanced accessibility and delignification | Lignin, sugars, acids | Partially removed, improves digestion |

Highlights

- Background and Motivation: Driven by global demand for sustainable energy solutions.

- Lignocellulosic Feedstock: Plant biomass composed of cellulose, hemicellulose, and lignin from various sources.Utilizes a wide range of agricultural residues, forestry residues, and dedicated energy crops, maximizing the use of renewable resources.

- Role of Pretreatment: Vital for breaking down biomass structure for better enzymatic hydrolysis. Critical for enhancing the digestibility of lignocellulosic feedstocks by breaking down complex structures and making cellulose more accessible for microbial digestion.

- Types of Methods: Covers physical, chemical, physicochemical, and biological methods, each with distinct mechanisms to disrupt lignin, hemicellulose, and cellulose structures.

- Single Method: Highlights specific single pretreatment methods such as Mechanical Comminution, Hydrothermal Pretreatment, and Enzymatic Hydrolysis, detailing their advantages and applications.

- Combined Methods: Enhances efficiency by leveraging strengths of different pretreatments.

- Industry Applications: Insight into current applications and advancements by Indian companies, demonstrating real-world implementation and success stories in ethanol production.

- Technological Innovations: Highlights emerging pretreatment technologies like Ionic Liquid Pretreatment and Deep Eutectic Solvent (DES) Pretreatment, showcasing their potential to revolutionize ethanol production. Ongoing innovation is needed to improve pretreatment technologies. Identifies ongoing challenges and underscores the necessity for continued research to overcome these barriers and enhance pretreatment technologies.

- Optimization Strategies: Discusses the critical parameters for optimizing pretreatment processes, including temperature, pressure, and catalyst selection, to achieve maximum efficiency and biogas yield.

Conclusion

The comprehensive analysis of pretreatment methods for lignocellulosic biomass reaffirms the pivotal role this step plays in advancing the efficiency of bioethanol production. The complexity of lignocellulosic structure necessitates robust and carefully selected pretreatment strategies to improve cellulose accessibility and maximize fermentable sugar yields.

The study of individual and combined pretreatment approaches—ranging from steam explosion and acid hydrolysis to advanced methods like ionic liquids and deep eutectic solvents—demonstrates that there is no universally optimal method. Instead, the effectiveness of a pretreatment strategy is highly dependent on the specific characteristics of the feedstock and the intended processing goals.

Particularly promising are combined pretreatment techniques, which leverage the synergistic effects of physical, chemical, or enzymatic steps to overcome biomass recalcitrance more efficiently. These hybrid approaches offer a path toward more cost-effective, scalable, and environmentally sustainable solutions. Ultimately, an in-depth understanding and strategic application of pretreatment technologies will be instrumental in unlocking the full potential of lignocellulosic bioethanol as a viable alternative to fossil fuels.