Key Questions Answered in this Section

- What is sawdust, and how is it generated in India?

- How much sawdust is produced annually in India?

- What are the key characteristics of sawdust as an industrial feedstock?

- Why is sawdust considered a reliable year-round biomass resource?

- Which regions in India generate the most sawdust?

- Which industries in India generate the most sawdust?

- What are the current and emerging uses of sawdust in various industries?

- How is sawdust priced, and what factors influence its cost in India?

- What are the challenges associated with storing and handling sawdust?

- How is sawdust utilized in industrial heating and power generation in India?

- What are the key challenges in using sawdust briquettes for biomass boilers?

- Is it possible to use sawdust in loose form in boilers?

Introduction

Sawdust refers to the residue that is generated from places where wood logs are processed. In India (as well as in many other countries worldwide), these are in the form of sawmills, plywood factories, and furniture-making units.

Typically, the logs are brought to the processing unit in the raw or semi-processed form (barks removed), and the processing facility undertakes the finer processing of the material into its final product – this could be cut pieces of wood (for sawmills), well-finished plywood material (for plywood factories) and fully finished or semi-finished furniture & accessories for furniture makers.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Given the extensive presence of these facilities across India, significant quantities of sawdust are generated in India, which can be utilized as a valuable feedstock for numerous applications and end uses.

In this article, we are going to explore the price trends, availability of raw materials, and the proximate analysis of sawdust. Additionally, we will discuss the production of briquettes and pellets and their use in boilers as a sustainable fuel alternative.

Total Sawdust Generation in India

There are no official estimates for the total generation of sawdust in India. The BioBiz team undertook an analysis to arrive at this estimate, using benchmark secondary data and using inputs from primary research.

Our analysis suggests that India could be generating 8-10 million tons of sawdust every year, across the country. There are however some estimates that suggest a higher number, about 18 million tons per annum.

Assessing the availability of sawdust involves analyzing its proximate analysis to determine suitability for various applications.

Sawdust Characteristics

Sawdust is one of the most used feedstock for industrial biomass-based heating, as it has excellent characteristics. The proximate analysis of sawdust reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility.

| Characteristic | Raw Biomass | Briquette Form |

| Calorific Value (GCV) | – | 3600 kcal/kg |

| Moisture Content | 25-35% | 10-12% |

| Ash Content | 2% | 3% |

| Silica Content | 2-5% | 2-5% |

| Volatile Matter | 85% | 76% |

| Fixed Carbon | 13.5% | 20% |

| Bulk Density | 240 Kg/m3 | 615 Kg/m3 |

| Price | ₹4-4.5 per kg | ₹9 per kg |

Seasonality

Year-Round Availability: Sawdust is available throughout the year due to its continuous production in sawmills, irrespective of seasons. This makes it a reliable feedstock for biomass-based energy systems. Year-round availability of sawdust ensures a steady supply for producing briquettes and pellets, which are essential for consistent boiler operations.

Regional Availability

Regions with abundant sawdust availability can leverage this resource for use in boilers, promoting sustainable energy practices. Sawdust is widely available across almost all regions in India due to the extensive woodworking and timber industries. As sawmills and carpentry are common in both urban and rural areas, sawdust is a byproduct available throughout the country.

Given the importance of sawdust, BioBiz Team did detailed research from secondary sources as well as collected inputs from primary interactions. Here are the highlights:

- Wood processing facilities comprise mainly furniture makers, sawmills, and plywood factories.

- There are numerous small and medium wood processing facilities spread across India, present in almost every state.

- Almost every large state has a few clusters of these facilities available. Some clusters are large, with prominent ones being Yamuna Nagar in Haryana (plywood cluster), Nadiad in Gujarat near Ahmedabad (sawmill cluster), and Perumbavoor in Kerala (sawmill cluster) which have hundreds of individual units. Many other clusters spread across different states have 50-100 units in one location.

- Based on the research by BioBiz Team, we estimate that a small factory unit would generate about 1 tonne of sawdust & wood residues while a large mill could generate up to 10 tonnes. Taking an average of 5 tonnes per day per unit, a sawmill cluster with about 500 units could generate 2500 tonnes of sawdust and small wood residues every day – a substantial amount.

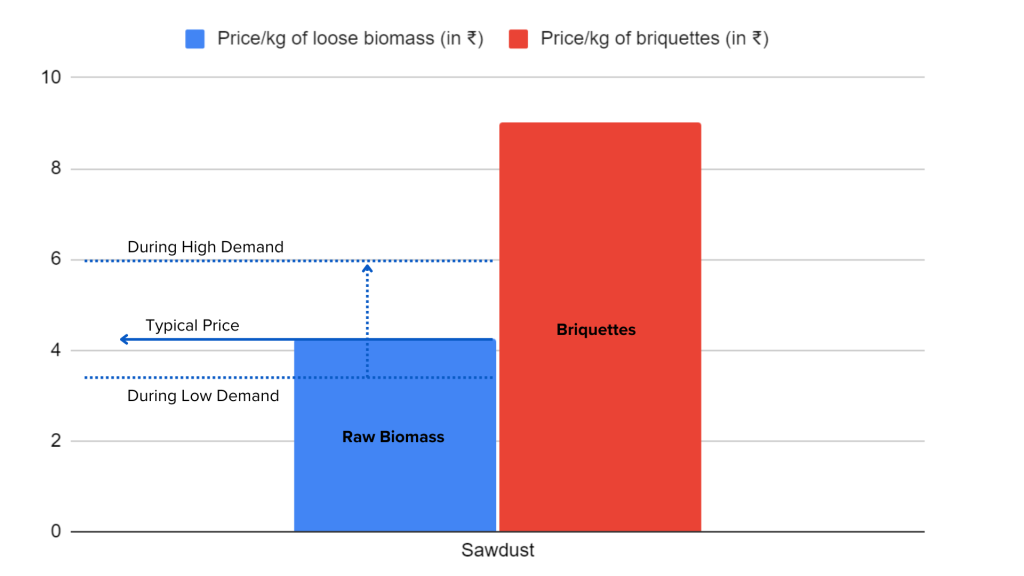

Prices

- Raw Biomass: Saw dust is typically available in the price range of 4-5 Rs/Kg.

- Price Range: Typically ₹4-4.5/kg; varies from ₹3.5 to ₹6/kg depending on factors.

- Briquette Price: When converted into briquettes, the price increases to around ₹9 per kilogram. The relatively high cost reflects its consistent demand and reliable supply chain. Fluctuations in sawdust price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use. The price may vary based on several factors.

- Seasonal Variations: Prices may rise in winter or monsoon due to demand and supply issues.

- Regional Differences: Wood-rich regions (e.g., Northeast, Western Ghats) may have lower prices; urban or remote areas may face higher costs due to transportation.

- Source Differences:

- Sawmills: Cheaper, bulk production.

- Furniture Makers: More expensive, finer quality sawdust.

- Type of Wood: Hardwood (furniture makers) sawdust is pricier than softwood (sawmills).

- Moisture & Quality: Dry, fine sawdust commands higher prices.

Price Volatility: Due to its rising demand in multiple industries, the price of sawdust has increased. In 2018, the average price for sawdust was around ₹2,000-3,000 per tonne, but due to increasing demand for wood pellets and bio-based materials, the price has surged to around ₹4000-4500 per tonne in some regions.

Uses of Sawdust

Current Uses

- Briquettes and Pellets: It is extensively used for making briquettes and pellets, which are used as a fuel source for industrial boilers and household heating.

- Agarbatti (Incense Stick) Manufacturing: Sawdust is commonly used in the production of agarbatti due to its fine particle size and ease of binding with aromatic substances.

- Animal Bedding and Mulch: Utilised as absorbent bedding for animals and as mulch in gardens.

- Spill Absorption: Effective for soaking up spills, such as oil or fuel, making it useful for cleaning up liquids.

- Others: Used for Mushroom cultivation, composting and soil amendment, paper & pulp industry.

Emerging Uses

- Adsorbent for Pollutant Removal: Processed into activated carbon for removing contaminants from industrial wastewater.

Storage of Sawdust

Given its extensive use, especially as a bio-fuel, sawdust will need to be stored at multiple points along its value chain – at the source (sawmill/plywood mill etc), briquetting unit and at the end user location.

Storage Considerations

- Moisture Control: Sawdust needs to be stored in dry conditions to prevent moisture absorption, which can lower its calorific value and combustion efficiency. High moisture content in loose sawdust can lead to mold growth, decomposition, and reduced calorific value during long-term storage, compromising its fuel quality and combustion efficiency. Proper drying and moisture control are essential to maintain its usability.

- Aeration and Protection from Pests: Adequate aeration is required to prevent mold and fungal growth, while the storage area should be protected from pests that could degrade the quality of the feedstock.

- Bulk Storage: Sawdust, due to its fine particle size, can be stored in large silos or in covered warehouses to avoid exposure to rain and other environmental factors.

- Studies show that spontaneous combustion in biomass can occur due to self-heating from microbial activity and chemical oxidation processes, particularly in materials with high moisture content.

- Dust explosions are a documented hazard in biomass storage, particularly in processing facilities where fine particles accumulate.

Precautions to Reduce Fire Risk

- Moisture Control: Keep moisture content low to avoid excessive heating.

- Ventilation: Ensure proper air circulation to dissipate heat buildup and prevent hot spots.

- Temperature Monitoring: Regularly monitor temperature inside biomass piles to detect any abnormal increases early.

- Compaction: Compact biomass to reduce the amount of oxygen available, minimizing the risk of ignition.

- Dust Control: Implement dust suppression systems to prevent dust accumulation in the air and reduce explosion risk.

Sawdust as Feedstock – Key Challenges

1. Fragmented Collection Mechanism

Many small-scale sawmills, often operating informally, contribute to sawdust production. This creates a fragmented collection system, which hampers the consistent supply of feedstock. A 2019 study by the Indian Council of Forestry Research and Education (ICFRE) noted that over 75% of sawdust is produced by small, unregistered units, making organized collection difficult.

2. High Moisture Content

- Storage and Drying Issues: Sawdust typically has a high moisture content which makes it unsuitable for immediate use as biomass without drying. This adds extra processing costs. Furthermore, due to India’s diverse climate, especially during monsoon seasons, storage is a challenge, as sawdust can absorb more moisture from the environment, further complicating its use.

- Cost of Drying: Drying sawdust to a moisture content of around 10-15%, which is optimal for energy production (like in pelletization or briquetting), incurs additional costs. On average, drying costs can range between ₹500-800 per tonne depending on the technology used, though in many cases, sawdust is left out to dry over a few days on its own.

3. Multiple Uses and Market Demand

Sawdust is increasingly being used in a variety of other industries, such as in the production of particle boards, wood pellets, animal bedding, and compost. The market for wood pellets, for instance, is growing due to both domestic consumption and export demand.

4. Environmental and Policy Barriers

- Sustainability Concerns: Despite sawdust being a waste product, there are growing concerns about the sustainability of its sourcing. Large-scale reliance on sawdust as feedstock could indirectly encourage deforestation, as India already faces challenges related to illegal logging. India’s forest cover increased by only 0.28% between 2019 and 2021, according to the Forest Survey of India, raising concerns about the capacity to sustainably supply wood-based byproducts like sawdust.

- Regulatory Challenges: Biomass energy policies in India, though incentivizing, are still in development. The National Policy on Biofuels 2018 promotes biomass as a renewable energy source, but there is limited regulatory oversight and support specifically for sawdust utilization. This lack of clear guidelines and support can slow investments in sawdust-based energy projects.

5. Challenges In Using Sawdust Briquettes as a Feedstock In Boilers

- Inconsistent fuel quality due to high moisture content (25-35%) affecting combustion efficiency and increasing fuel consumption.

- Fuel bridging and plugging in handling systems like hoppers and augers, leading to feed interruptions and downtime.

- Incomplete combustion resulting in higher carbon monoxide (CO) emissions and unburned hydrocarbons.

- Ash fouling on heat transfer surfaces due to volatile compounds and alkali metals in sawdust, reducing efficiency and increasing maintenance.

- Need for specialized grates or burners to manage fine particle size and ensure complete combustion.

- Increased corrosion risks from corrosive compounds formed during combustion, reducing the boiler’s lifespan.

- Frequent maintenance and downtime due to fouling, slagging, and ash production challenges.

Sawdust for Industrial Heating and Power Generation

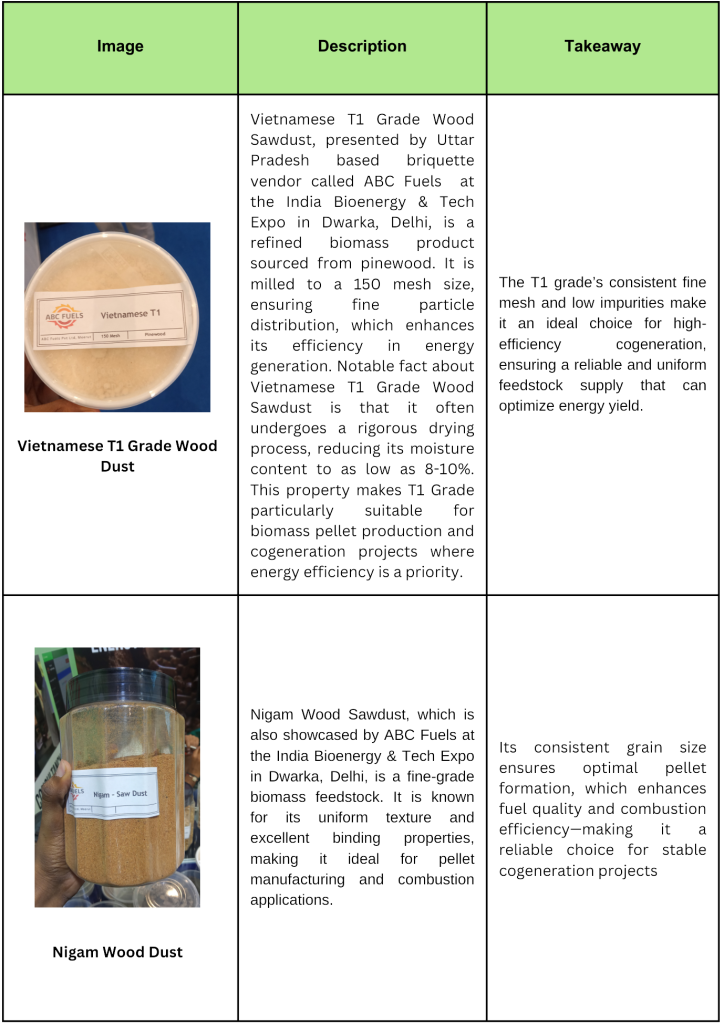

Sawdust has seen an uptick in demand across India’s industrial landscape, primarily for heating and power generation. As industries strive for sustainable and cost-effective alternatives, sawdust emerges as a promising solution. This section explores the various aspects of sawdust usage for industrial heating in India, its benefits, challenges, and adoption by different sectors.

1. Uses of Sawdust for Industrial Heating and Power Generation

In India, sawdust is increasingly used for biomass heating and power generation, particularly in industries seeking eco-friendly alternatives to fossil fuels. The sawdust, when burned, generates substantial heat, making it an effective fuel source for several industrial applications. The major uses of sawdust in India include:

- Boiler Fuel: Sawdust is a primary fuel for boilers in various manufacturing industries, where it is burned to produce steam for heating or power generation.

- Cogeneration Plants: Some industrial units utilize sawdust for cogeneration—a system that produces both electricity and useful heat simultaneously. This not only improves efficiency but also minimizes carbon footprints.

- Pellet Production: Sawdust is compressed into pellets, which serve as a convenient and high-energy fuel for both industrial heating and power plants.

- Heat Energy in Kilns and Dryers: Sawdust is used in industries like brick manufacturing and food processing, where high and consistent temperatures are required for drying and heating purposes.

2. Form in Which Sawdust is Used in Industries

Sawdust can be utilized in several forms depending on the industrial requirement:

- Loose Sawdust: Directly collected and used in some industrial boilers, though it has issues with consistent burning.

- Sawdust Briquettes: Compact, cylindrical blocks of sawdust offering higher energy density and easier handling. These are favored in larger industrial setups.

- Sawdust Pellets: These are small, dense, and uniform in size, making them ideal for automatic feeding systems in industrial boilers. They have a lower moisture content, which increases combustion efficiency.

- Treated Sawdust: Chemically treated to remove impurities, this form is sometimes used to ensure cleaner combustion and to prevent boiler corrosion.

3. Boilers Using Sawdust

In India, sawdust is mainly used in biomass boilers, which have become popular due to their cost efficiency and adaptability to different biomass materials. A few prominent types of boilers that use sawdust include:

- Fluidized Bed Combustion (FBC) Boilers: These are designed to handle a variety of biomass fuels, including sawdust. FBC boilers provide better efficiency as they mix and burn the sawdust uniformly.

- Stoker Boilers: Commonly found in medium to large industries, these boilers use a feeding mechanism to supply sawdust continuously, allowing for consistent heating.

- Pellet Boilers: Used by industries that rely on sawdust pellets. These boilers are designed for automatic operation and higher efficiency due to the uniform size of pellets.

Several manufacturers in India produce biomass boilers, such as Thermax, Forbes Marshall, and Cheema Boilers, offering customized solutions for industrial needs.

4. Amount of Sawdust Being Used by Industries for Industrial Heating

The exact volume of sawdust used for industrial heating in India varies by sector. However, estimates suggest that:

- Indian industries use approximately 10 to 12 million tons of biomass (including sawdust) annually for industrial heating.

- A medium-sized industrial unit may consume 5 to 10 tons of sawdust per day for heating purposes, while larger facilities may use over 50 tons daily.

- The paper and pulp industry, which uses significant biomass for steam generation, can consume up to 1.5 million tons of sawdust annually.

With the rise in biomass-based energy solutions, the use of sawdust in India is anticipated to grow by 8-10% annually over the next decade.

5. Prominent Industries Using Sawdust for Industrial Heating

Several industries across India are at the forefront of utilizing sawdust for industrial heating:

- Pulp and Paper Industry: A major consumer of biomass energy, particularly sawdust, for steam and electricity generation.

- Brick Manufacturing: Uses sawdust as a heat source in kilns for firing bricks, replacing traditional coal and lignite.

- Textile Industry: Some textile manufacturers utilize sawdust boilers to generate steam for fabric dyeing and other processes.

- Food Processing: In industries like sugar refining and tea processing, sawdust is used for drying and heating needs.

- Pharmaceutical Sector: Utilizes biomass-based boilers for steam generation, especially in areas with reliable sawdust availability.

Sawdust – From Field to Findings