Key Questions Answered in this Section

- What are the main uses of bamboo as a biomass feedstock in India, and why is it gaining popularity?

- How does bamboo’s high cellulose content contribute to its efficiency in bioethanol and biogas production?

- What is the annual bamboo generation in India, and which states are the leading producers?

- How is bamboo used in bioenergy applications such as briquettes, pellets, and cogeneration systems?

- What challenges are associated with processing and storing bamboo biomass for industrial heating?

- How does bamboo compare with traditional biomass fuels like wood chips and bagasse in terms of calorific value and sustainability?

- How are fluidized bed boilers adapted for bamboo combustion, and why are they preferred in industries?

- What role does bamboo play in India’s renewable energy goals, including its contribution to 2G ethanol refineries and CBG production?

- How is bamboo being used in the cement, paper, and textile industries to reduce reliance on fossil fuels?

- What government initiatives, such as the National Bamboo Mission, are driving the adoption of bamboo as a biomass feedstock?

- How is the price of bamboo as a feedstock determined, and what factors influence its cost in loose and briquette form?

- Is it possible to directly use bamboo in boilers?

Introduction

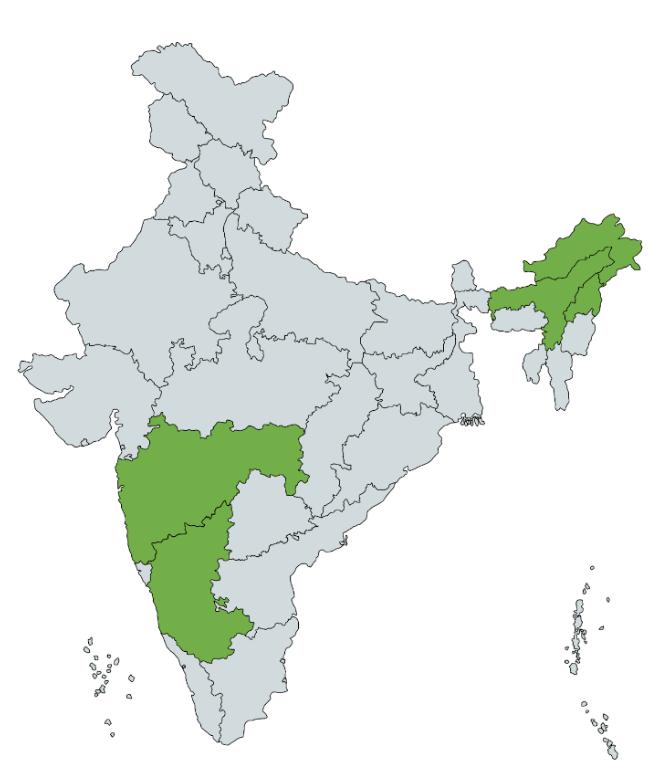

In India, bamboo is emerging as a significant biomass feedstock due to its fast growth, abundant availability, and versatility. As the second-largest bamboo producer globally, India has approximately 14 million hectares dedicated to bamboo cultivation, primarily in the Northeastern states, Madhya Pradesh, Maharashtra, and Odisha. Recognized for its potential to drive rural development and support sustainable industries, bamboo is increasingly utilized for bioenergy, biofuel, and bioproducts.

Bamboo’s high cellulose content (40-50%) makes it ideal for generating bioethanol, biogas, and biomass pellets, which serve as cleaner alternatives to conventional fuels. It is also used in producing biochar, which enhances soil quality and sequesters carbon. With the Indian government’s focus on promoting bamboo-based industries through initiatives like the National Bamboo Mission, bamboo feedstock is playing a pivotal role in supporting local economies, reducing deforestation, and advancing India’s renewable energy goals.

Let us look into the price, availability, and proximate analysis of bamboo briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Total Bamboo Generation in India

Our secondary and primary research has indicated that about 33 million tonnes of bamboo are harvested every year across India. Assessing the availability of bamboo involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of bamboo reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Parameter | Loose Form | Briquette Form |

| Gross Calorific Value (GCV) | —- | 4200 Kcal/kg |

| Moisture Content | 14-19% | 7-10% |

| Ash Content | 2% | 3-4% |

| Silica Content | 4-5% | 5-7% |

| Volatile Matter | 75% | 73% |

| Fixed Carbon | 10% | 10-12% |

| Bulk Density | 540-600 Kg/m3 | 900-1000 Kg/m3 |

Regional Availability

Regions with abundant bamboo availability can leverage this resource for use in boilers, promoting sustainable energy practices. While there is no official data on the amount harvested pan-India, harvest estimates have been arrived at using metrics BioBiz arrived at using harvested and cultivated amounts for specific states for which data are available. The following table lists the top 5 states where bamboo is abundant.

| State | Total Growing Stock Annually (in million TPA) | Total Harvested Annually (approx.) (in million TPA) |

| Arunachal Pradesh | 27.9 | 3.3 |

| Maharashtra | 26.5 | 3.2 |

| Karnataka | 26.4 | 3.2 |

| Assam | 24.0 | 2.8 |

| Nagaland | 20.5 | 2.4 |

Seasonality of Bamboo

The following table outlines the seasonal aspects of bamboo cultivation, including the best time for planting, growth duration, maturity period, and harvesting schedule. It also highlights the intercropping opportunities during the initial years of cultivation, providing a clear timeline for effective bamboo farming.

| Aspect | Details |

| Optimal Planting Season | Rainy season (June to September in India) |

| Growth Duration | Bamboo plants reach full height in 6-9 months |

| Maturity Period | 3 to 5 years for the bamboo culms to mature and be ready for harvesting |

| Harvesting Season | Throughout the year once maturity is reached; selective harvesting recommended to avoid damaging the plant |

| Intercropping Period | First 3 years after planting (farmers can grow turmeric, chilies, or ginger for additional income) |

Uses of Bamboo

Current Uses

Here’s an overview of the utilization of bamboo for various applications in India in 2020

| Application | Percentage of Utilization of Bamboo |

| Construction & Fencing | 40% |

| Furniture and Handicrafts | 20% |

| Flooring | 30% |

| Paper & Pulp | 10% |

- Construction & Fencing: Bamboo is a rapidly renewable grass, and its cultivation requires minimal resources like water and fertilizer. It is extremely lightweight as compared with hardwoods and has a great capacity for shock absorption, which makes it particularly useful in earthquake-prone areas. Bamboo is also used for fencing along highways.

- Furniture and Handicrafts: Bamboo, with its natural aesthetic appeal, durability, and flexibility, has emerged as a sought-after material for crafting a wide range of furniture, home decor items, and handicrafts. The bamboo handicraft has helped many individuals to secure a job for themselves.

- Flooring: Bamboo flooring is popular in India due to its abundance, especially in the tropical rainforest regions of Asia. It is an inexpensive alternative to hardwood flooring. Its natural beauty, renewability, and sturdiness make it an exotic outdoor wood flooring.

- Paper & Pulp: Bamboo is a natural indigenous fibrous raw material that plays a key role in the paper and pulp industry in India. It is used by several pulp and paper industries in the country. Bamboo is the best raw material for manufacturing high-strength paper due to its high cellulose content, thin, solid fiber, good plasticity, and fiber length. However, the use of bamboo for pulping has declined over the years.

Emerging Uses

In recent years, bamboo has emerged as a versatile resource in India, finding applications across various sectors. Here’s a glimpse into its diverse uses and the growing trend:

Construction Boom: Bamboo’s exceptional strength-to-weight ratio has led to its increased adoption in construction. India’s National Bamboo Mission reports a significant rise in bamboo-based construction projects, accounting for over 5 lakh (500,000) houses constructed between 2018-2022.

Green Alternative to Wood: With deforestation concerns rising, bamboo serves as a sustainable alternative to wood. India’s bamboo cultivation area has expanded to over 3.60 million hectares, marking a 118% increase since 2014.

Thriving Handicraft Industry: The handicraft sector in India has capitalized on bamboo’s versatility. As of 2023, the sector employs over 7 million artisans, with bamboo crafts contributing to a substantial portion of their livelihoods.

Eco-Friendly Packaging Solutions: Bamboo-based packaging has gained traction amidst global efforts to reduce plastic usage. Indian companies have increasingly turned to bamboo-based packaging, with over 200 metric tonnes of bamboo packaging material produced annually since 2020.

Innovative Textile Industry: Bamboo fibers, renowned for their softness and breathability, are revolutionizing the textile industry. India’s bamboo fiber production has surged by 25% annually since 2019, reaching 20,000 metric tonnes in 2023.

Bioenergy Production: Bamboo’s rapid growth and high calorific value make it an ideal feedstock for bioenergy production. India’s bioenergy sector has witnessed a 30% increase in bamboo-derived biofuel production, contributing to the nation’s renewable energy goals.

Climate Resilience: Bamboo’s extensive root system aids in soil stabilization and erosion control, making it invaluable for climate resilience efforts. The Indian government’s initiatives include planting over 500 million bamboo saplings in degraded lands by 2025 to mitigate the impact of climate change.

Rural Livelihood Enhancement: Bamboo cultivation provides a sustainable source of income for rural communities. The average annual income of bamboo farmers has doubled in the last decade, with over 2 million farmers engaged in bamboo cultivation as of 2023.

2G Ethanol Refineries: The 2G ethanol refineries being set up in India that are known to use bamboo for ethanol production:

- Nagarjuna Group, Hyderabad and Lodga Bamboo Industries, Latur: The world’s first ethanol production refinery project from bamboo with a daily capacity of 30,000 litres is being built in India1. The agreement for the ethanol refinery project was signed between Nagarjuna Group, Hyderabad, and Lodga Bamboo Industries in Latur district1. This refinery project will be the first in the world to produce 30,000 litres of ethanol per day from bamboo.

- ABRPL Facility, Assam: The implementation of India’s first 2G Ethanol production plant from bamboo-based feedstock is in full swing at the ABRPL facility in Assam.

- Assam Biorefinery: The Assam biorefinery, which cost NRL and its Finnish partners Chempolis and Fortum 40 billion rupees, is India’s first to use bamboo as feedstock and is expected to annually produce 50,000 tonnes of ethanol.

Compressed biogas (CBG) production:

- Biogas Potential: Bamboo has a high cellulose content, making it a suitable feedstock for biogas production. The anaerobic digestion of bamboo biomass can yield biogas, primarily composed of methane and carbon dioxide.

- Renewable Energy: Utilizing bamboo for CBG production aligns with India’s renewable energy goals. The Indian government aims to increase the share of renewable energy in the total energy mix to 40% by 2030.

Storage of Bamboo Feedstock

Air Drying:

- Method: Bamboo culms (stems) are cut and stored under shaded, well-ventilated areas to allow natural drying.

- Advantages: Cost-effective and reduces moisture content gradually, preventing cracking.

- Duration: Generally takes 1-3 months, depending on weather conditions and bamboo thickness.

Water Soaking:

- Method: Freshly cut bamboo is submerged in ponds, rivers, or tanks for about 2-6 weeks.

- Purpose: Removes starches and sugars, which are prone to insect and fungal attacks.

- Advantages: Enhances bamboo’s durability and reduces susceptibility to pest infestation.

Chemical Treatments:

- Borax-Boric Acid Solution: Bamboo is soaked or pressure-treated with a solution of borax and boric acid to deter insects.

- CCA (Chromated Copper Arsenate): Effective but often avoided due to environmental concerns.

- Duration: Soaking can range from a few hours to several days, depending on the treatment method.

Heat Treatment (Kiln Drying):

- Method: Bamboo is placed in a kiln for controlled heating, reducing moisture content to about 12-15%.

- Advantages: Rapid drying and effective sterilization against insects and fungi.

- Duration: Typically 1-2 weeks.

- Considerations: This can cause cracking if not properly managed.

Smoking or Traditional Preservation:

- Method: Involves storing bamboo over a slow-burning fire or in smokehouses.

- Advantages: Reduces moisture and adds some resistance to pests.

- Usage: Common in rural or traditional bamboo-processing areas.

Storage Conditions:

- Ventilation: Essential for reducing humidity and avoiding mold growth.

- Elevation: Bamboo should be stored off the ground to prevent moisture absorption from the soil.

- Covering: The use of tarps or natural covers (like palm leaves) helps to shield bamboo from direct sunlight and rain.

Moisture Content Monitoring:

- Target: Ideal moisture content for bamboo biomass storage is around 15-20%.

- Tools: Moisture meters are often used to check the readiness of bamboo for storage or use.

Proper storage ensures that bamboo briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Bamboo as Feedstock – Key Challenges

1. Moisture Content and Drying Requirements

- Challenge: Fresh bamboo has a high moisture content (up to 50-70%), which can significantly reduce combustion efficiency.

- Impact: High moisture levels result in lower calorific value and increased emissions during burning.

- Solution: Requires effective drying processes (air drying, kiln drying), which can be time-consuming and add to the cost.

2. Storage and Pest Infestation

- Challenge: Bamboo is prone to attack by pests (e.g., beetles, termites) and fungi due to its high starch and sugar content.

- Impact: Improper storage can lead to degradation, reducing the quality and calorific value of the feedstock.

- Solution: Implementing chemical treatments (e.g., boric acid), proper storage conditions (e.g., ventilation, elevation), and periodic inspections are necessary, which increases operational complexity.

3. Ash and Silicon Content

- Challenge: Bamboo has relatively high ash and silicon content compared to other biomass feedstocks like wood.

- Impact: This can cause slagging, fouling, and corrosion in combustion systems, leading to higher maintenance costs and equipment wear.

- Solution: Advanced combustion technologies and ash management systems are needed, adding to the setup and operational costs.

4. Uniformity and Quality Control

- Challenge: Bamboo feedstock can vary significantly in quality, density, moisture content, and chemical composition due to differences in species, age, and growing conditions.

- Impact: Inconsistent feedstock quality can lead to inefficient combustion or processing, impacting energy yield and biomass product quality.

- Solution: Requires stringent quality control measures and standardized harvesting and processing practices, which may be resource-intensive.

5. Logistics and Handling

- Challenge: Bamboo is bulky and lightweight, making transportation and handling difficult and costly.

- Impact: Higher logistics costs reduce the economic feasibility of bamboo as a large-scale biomass feedstock, especially if sourced from remote areas.

- Solution: Developing efficient transportation systems or on-site processing facilities can help, but they increase infrastructure costs.

6. High Processing Costs

- Challenge: Converting raw bamboo into usable biomass forms (like pellets, chips, or bioethanol) involves complex processing (e.g., chipping, drying, pelletizing).

- Impact: Increases operational costs and requires specialized equipment, which may not be readily available in all regions.

- Solution: Technological advancements are necessary to reduce processing costs, requiring significant research and development investment.

Bamboo for Industrial Heating and Power Generation

Uses of Bamboo for Industrial Heating and Power Generation

- Biofuel for Industrial Heating: Bamboo is a highly effective biomass due to its energy yield and sustainability. Industries in India, particularly in regions like the Northeast, Chhattisgarh, and Madhya Pradesh, utilize bamboo as a primary fuel source for heating processes. Its high carbon content and rapid growth (harvest cycle of 3-5 years) make it a preferred choice over traditional wood and coal.

- Power Generation: Bamboo is also leveraged for electricity generation, primarily in cogeneration plants that use biomass as a fuel. Cogeneration facilities extract energy more efficiently than traditional methods by generating electricity and utilizing waste heat for other industrial processes. The Government of India has promoted bamboo biomass for decentralized power generation, particularly in rural and semi-urban areas.

- Industrial Furnaces: Bamboo is used in furnaces for applications requiring consistent and reliable heating. Its high calorific value, ranging from 4,000 to 4,800 kcal/kg, allows it to serve as a substitute for coal and wood chips in several heat-intensive processes.

Forms in Which Bamboo is Used in Industries

- Bamboo Briquettes: Densified bamboo, pressed into briquettes, is the most common form for industrial heating. These briquettes have a high energy density, uniform shape, and consistent burn characteristics, making them ideal for industrial boilers and kilns. They are easier to store, transport, and feed into automated systems, contributing to operational efficiency.

- Bamboo Pellets: Bamboo is also processed into small, cylindrical pellets, which are used in modern biomass boilers. Pellets offer an excellent combustion rate and have low moisture content (around 10-15%), resulting in high efficiency. Bamboo pellets are a growing market in states like Odisha and Assam, where local industries are switching from coal to pelletized biomass.

- Raw Bamboo and Bamboo Chips: In areas where processing facilities are limited, industries often use raw bamboo or bamboo chips. These are shredded into smaller pieces to ensure an even burn in industrial furnaces or power plants. It remains an economical choice, especially in proximity to bamboo-growing regions.

Team BioBiz also found that bamboo dust is also being used for pelletizing.

Displayed by Superb Biofuels at the India Bioenergy & Tech Expo 2024 event held at Dwarka, Delhi in September 2024, these bamboo dust pellets represent a novel use of bamboo dust as a feedstock for biomass fuel. Before this expo, bamboo dust had not been widely recognized by us during our research. This was perhaps the only instance where we physically came across bamboo dust being used in pellets, even though we had heard that some briquette and pellet vendors were using it in northeast India.

Boilers Using Bamboo for Heating and Power Generation

- Fluidized Bed Boilers: These are the most common type of boilers utilizing bamboo. Fluidized bed combustion allows for the efficient burning of bamboo biomass, handling its variability in size and moisture content. These boilers also enable lower emissions and better control over combustion temperatures.

- Industrial Biomass Boilers: Several biomass boilers in India are designed to use bamboo pellets or briquettes. These boilers are equipped with automatic feeders, ash removal systems, and temperature controls, specifically adapted for the high ash content found in bamboo.

- Cogeneration Boilers: Cogeneration or CHP (Combined Heat and Power) plants are increasingly using bamboo biomass. These boilers utilize steam to generate electricity and capture the waste heat for secondary industrial processes, maximizing efficiency and reducing greenhouse gas emissions.

Amount of Bamboo Being Used by Industries for Industrial Heating

- Annual Consumption Data: As of 2023, India’s estimated industrial consumption of bamboo for biomass energy stands at 3.5 million metric tons annually. This number is projected to grow by 15% yearly, driven by increasing energy demands and government incentives for sustainable practices.

- Energy Yield Comparison: One metric ton of bamboo biomass can generate approximately 2.5 to 3 MWh of electricity, making it a competitive alternative to traditional biomass fuels like bagasse and wood chips.

- Biomass Share: Bamboo makes up around 8-10% of the total biomass fuel used in India’s industrial heating sector, with expectations of growth as infrastructure for bamboo processing and distribution improves.

Prominent Industries Using Bamboo for Industrial Heating

Brick Kilns and Ceramics: Bamboo briquettes are gaining traction as a preferred fuel for brick kilns and ceramic industries, replacing traditional firewood. These briquettes burn longer and at higher temperatures, contributing to better product quality and fewer pollutants.

Cement Industry: The Indian cement industry, particularly in regions like Meghalaya and Gujarat, has been one of the major adopters of bamboo biomass. Many cement kilns are now co-firing bamboo briquettes with coal to reduce carbon emissions and lower fuel costs.

Paper & Pulp Mills: Traditionally heavy users of wood chips, paper, and pulp mills are increasingly turning to bamboo, given its fibrous nature and availability. Companies in Kerala and West Bengal are setting up dedicated bamboo plantations to ensure a steady supply.

Textile Industry: Textile factories in Tamil Nadu are experimenting with bamboo biomass in boilers to generate steam required for various processes. Bamboo’s renewable nature aligns with the industry’s efforts to brand itself as eco-friendly and sustainable.

Power Plants: Small-scale power plants in rural and semi-urban areas, especially in Assam, Madhya Pradesh, and Odisha, are utilizing bamboo pellets in cogeneration systems. These initiatives are supported by the Indian government’s “National Bamboo Mission” which promotes bamboo cultivation and usage.