Key Questions Answered in this Section

- How much cumin seed husk biomass is generated annually in India, and what portion is currently utilized for energy applications?

- What are the key characteristics of cumin seed husks that make them suitable for biomass energy production?

- What forms of cumin seed husks (pellets, briquettes, or loose bulk) are most commonly used in industrial applications, and why?

- How do industries like food processing, textiles, and paper manufacturing integrate cumin husks into their energy generation processes?

- What types of boilers (e.g., fluidized bed or thermal oil heaters) are best suited for burning cumin seed husks, and why?

- What are the primary challenges associated with using cumin seed husks as a biomass feedstock, such as seasonal availability and storage issues?

- How does the calorific value and ash content of cumin husks compare to other biomass sources used in industrial heating?

- What role does the utilization of cumin seed husks play in reducing environmental impacts, such as agricultural waste burning and CO2 emissions?

- How are advancements in pelletization and briquetting technologies helping to overcome the logistical challenges of storing and transporting cumin husks?

- What economic and environmental benefits can industries and farmers gain from scaling up the use of cumin seed husks for renewable energy production?

- How is the price of cumin seed husks determined in both loose and briquette forms, and what factors influence its cost?

- Is it possible to directly use cumin seed husks in boilers?

Introduction

Cumin seed husks, the agricultural residues from cumin (Cuminum cyminum) cultivation, offer a promising biomass feedstock in India, where cumin is extensively grown, particularly in the arid and semi-arid regions of Rajasthan and Gujarat. These husks, traditionally left as agricultural waste after harvesting cumin seeds, are suitable for bioenergy production through combustion, gasification, and biochar generation.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Let us look into the price, availability, and proximate analysis of cumin seed husk briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Total Cumin Generation in India

In India, cumin occupies an area of 8.42 lakh hectares and the total production is 5.47 lakh tonnes (2019-20).Rajasthan and Gujarat have important position in terms of area and production and contribute 99% of the total production of cumin in India.

Assessing the availability of cumin seed husk involves analyzing its proximate analysis to determine suitability for various applications. The proximate analysis of cumin seed husk reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

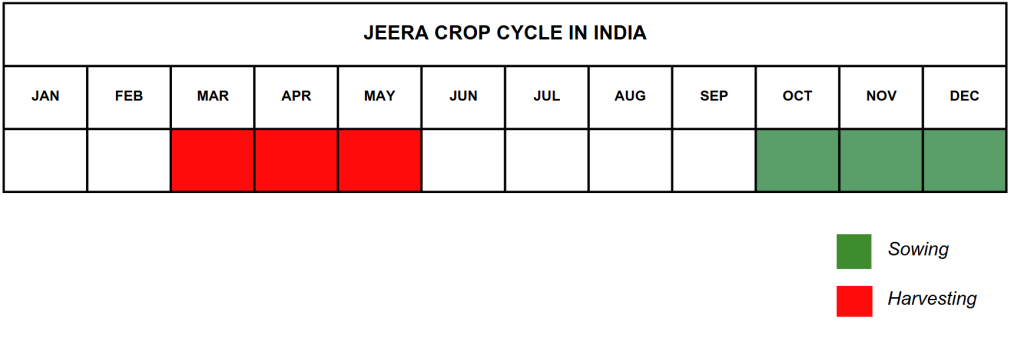

Seasonality

In India, Jeera is grown as a Rabi crop. Sowing is done from October to December while harvesting starts from February onwards. It requires less water and more cold for its better growth with an ideal temperature of 25 to 30 degrees. Jeera crop is highly sensitive to rain/ high humidity and if rain occurs during harvesting time, the quality of the Jeera gets badly affected (it turns black. The major producing states are Gujarat and Rajasthan in India.

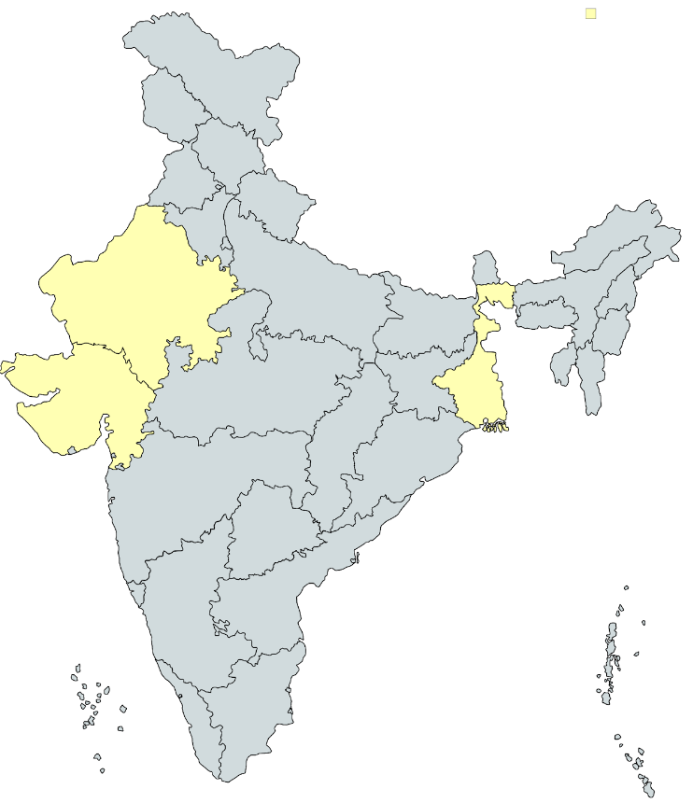

Regional Availability

Regions with abundant cumin seed husk availability can leverage this resource for use in boilers, promoting sustainable energy practices.

| State | Annual Cumin Production (Lakh Tonnes Per Annum) | Key Regions of State |

| Gujarat | 3.16 | Saurashtra, Central Gujarat, Mehsana, Banaskantha, Patan, Junagarh, Jamnagar, Rajkot, Bhavnagar, Amreli, Surendra Nagar |

| Rajasthan | 2.3 | Baran, Chittorgarh, Jhalawar, Alwar, Jaipur, Nagaur, Sri Ganganagar, Hanumangarh, Bikaner, Jalore, Jodhpur, Barmer |

| West Bengal | 0.01 | Nadia |

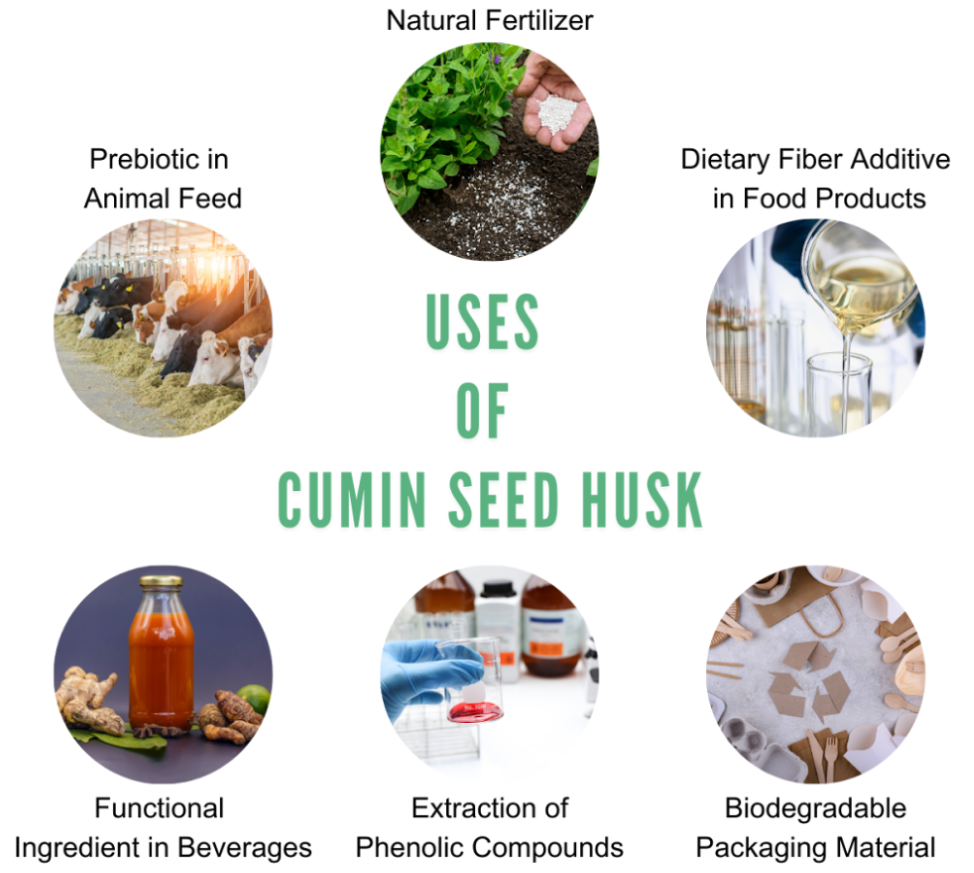

Uses of Cumin Seed Husk

Current Uses

- Dietary Fiber Additive in Food Products: Cumin seed husk is already utilized in the food industry to add fiber to baked goods, enhancing nutritional value without altering taste.

- Prebiotic in Animal Feed: Its use in livestock feed as a prebiotic for gut health is an established practice, particularly in poultry and cattle industries to improve digestion and nutrient absorption.

- Natural Fertilizer: Cumin husk is composted as an organic fertilizer in agriculture, enriching soil quality, especially in organic farming practices.

Emerging Uses

- Functional Ingredient in Beverages: Adding cumin seed husk powder as a fiber supplement in health drinks and smoothies is a developing trend, aligning with increasing consumer demand for functional foods.

- Biodegradable Packaging Material: Research into using cumin husk fibers in biodegradable packaging materials is on the rise as industries look for sustainable alternatives to plastic.

- Source for Extraction of Phenolic Compounds: The extraction of phenolic compounds for use in natural antioxidants and cosmetics is a newer exploration, driven by interest in natural preservatives and eco-friendly cosmetic ingredients.

Storage

Proper storage ensures that cumin seed husk briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Dry Storage in Silos or Bins

- How: Dried and stored in large, ventilated silos or bins.

- Benefits: Prevents mold growth and degradation.

- Conditions: Low humidity, stable temperature, and adequate ventilation.

Compression and Pelletization

- How: Husks are compressed and pelletized to reduce bulk.

- Benefits: Saves storage space, minimizes spoilage, and ensures consistent feedstock size.

- Conditions: Pellets should be stored in a dry, controlled environment to prevent disintegration.

Bulk Storage in Controlled Warehouses

- How: Stored in warehouses with temperature and humidity control.

- Benefits: Prevents spoilage and insect infestations; ideal for large-scale storage.

- Conditions: Requires insulation, ventilation, and pest control for optimal storage.

Wrapped or Covered Bales

- How: Husks are baled and wrapped in protective materials like plastic wrap or tarps for outdoor storage.

- Benefits: Protects from environmental factors (rain, insects); suitable for outdoor storage when indoor space is limited.

- Conditions: Bales should be securely wrapped and stored off the ground to avoid moisture from below.

Vacuum-Sealed Packaging for Long-Term Storage

- How: Husks are vacuum-sealed to prevent oxidation and spoilage.

- Benefits: Extends shelf life and minimizes space by eliminating air.

- Conditions: Best for smaller quantities due to cost considerations; ideal for preserving quality over extended periods.

Cumin Seed Husks as Feedstock – Key Challenges

High Moisture Content

- Challenge: Fresh cumin husks may retain moisture, leading to mold, microbial growth, and reduced energy efficiency during combustion.

- Solution: Additional drying processes are needed, which increase costs and energy consumption.

Low Bulk Density

- Challenge: Cumin seed husks have a low bulk density, making them difficult to store and transport in large quantities without compacting.

- Solution: Compression or pelletization can help but adds an extra processing step, requiring specific machinery.

Ash Content and Fouling

- Challenge: Biomass with high ash content can cause fouling and slagging in combustion systems, leading to maintenance issues and equipment wear.

- Solution: Adjustments in combustion equipment or blending with other biomass types may reduce these effects but require technical adaptation.

Inconsistent Composition and Quality

- Challenge: Variability in husk composition affects energy output, efficiency, and compatibility with biomass processing systems.

- Solution: Quality control measures are needed to maintain consistency, but this adds to operational complexity and cost.

Seasonal Availability

- Challenge: Cumin seed husks are produced seasonally, which can lead to an irregular supply and necessitate large-scale storage solutions to maintain a steady feedstock supply year-round.

- Solution: Investing in storage facilities to keep husks for extended periods or finding alternative feedstock sources during off-seasons.

Dust Generation and Handling Risks

- Challenge: Cumin husks produce fine dust when processed, posing health risks and increasing the risk of combustion or explosion in storage areas.

- Solution: Dust control measures, such as proper ventilation, dust collection systems, and protective equipment, are necessary but can be costly to implement.

Cumin Seed Husks for Industrial Heating and Power Generation

Uses of Cumin Seed Husks for Industrial Heating and Power Generation

Cumin seed husks serve multiple purposes in industrial settings:

- Biomass Fuel: Cumin seed husks are used as a biomass fuel, contributing to the generation of heat and energy. Biomass has gained traction as a renewable energy source in India, particularly in industries looking to reduce carbon footprints.

- Steam Generation: In industries, husks are combusted in boilers to generate steam, which is then used for heating processes or to drive turbines for electricity generation.

- Carbon Neutral Energy: Utilizing cumin husks as a fuel source is considered carbon-neutral, as the CO2 emitted during combustion is offset by the CO2 absorbed during the growth of the cumin plants.

Form in which Cumin Seed Husks are Used in Industries

Cumin seed husks are primarily utilized in the following forms:

- Pellets: The husks are often processed into pellets, which are easier to handle and have a higher energy density. Pellets ensure consistent combustion and are ideal for use in biomass boilers.

- Loose Bulk: In some cases, industries utilize loose husks for direct combustion in traditional furnace systems. This method is less efficient but can be cost-effective for smaller operations.

- Briquettes: Similar to pellets, briquettes are compacted forms of husks, offering an efficient burning rate and ease of storage.

Boilers Using Cumin Seed Husks

Cumin seed husks are increasingly being used in various types of boilers across industries:

- Thermal Oil Heaters: Industries requiring high-temperature heat transfer are adopting thermal oil heaters that can efficiently burn cumin husks.

- Fluidized Bed Boilers: These boilers provide better combustion efficiency and are suitable for burning low-density fuels like cumin husks. They are capable of handling varying sizes of husk particles, making them versatile for industrial applications.

- Industrial Steam Boilers: Many food processing and agro-based industries are integrating husks into their existing steam boiler systems, contributing to operational cost savings and enhanced energy efficiency.

Amount of Cumin Seed Husks Being Used by Industries for Industrial Heating

While specific statistics on the exact volume of cumin seed husks utilized for industrial heating are limited, estimates indicate that India produces approximately 550,000 tons of cumin annually. A significant portion of this production results in husks, with industry stakeholders utilizing about 15-20% of this waste for energy generation. This translates to roughly 75,000 to 100,000 tons of husks being converted into biomass fuel each year.

Prominent Industries Using Cumin Seed Husks for Industrial Heating

Several industries in India have begun harnessing the potential of cumin seed husks:

- Food Processing Industry: Companies involved in spice processing and packaging are utilizing cumin husks in their boilers for steam generation. This not only cuts down on energy costs but also reduces waste.

- Textile Industry: Some textile manufacturers are adopting cumin husks in their production processes, where they require substantial amounts of heat for dyeing and finishing fabrics.

- Paper and Pulp Industry: The paper industry is increasingly focusing on sustainable practices, with cumin husks being used as an alternative fuel source for steam generation in paper mills.

- Bioenergy Plants: Dedicated bioenergy facilities in states like Gujarat and Rajasthan are leveraging cumin husks to produce electricity, thereby promoting the circular economy.