Key Questions Answered in this Section

- What are corn cobs, and how are they generated as a by-product of maize processing?

- How much corn cob biomass is generated annually in India, and what are its primary uses?

- What are the characteristics of corn cobs in loose and briquette forms?

- Why are corn cobs considered an efficient biomass feedstock for industrial heating and power generation?

- What are the challenges in storing corn cobs, and how can losses be minimized?

- Which states in India produce the most corn cobs, and what regions are key contributors?

- What are the emerging uses of corn cobs, such as in xylitol and furfural production?

- What forms of corn cob biomass (whole, chipped, or pellets) are used in industrial applications?

- How do industries like food processing, textiles, and paper manufacturing utilize corn cobs?

- How does the use of corn cobs for biomass energy help reduce greenhouse gas emissions compared to coal?

- Is it possible to directly use corn cobs in boilers?

Introduction

Corn cobs are the central core of maize ears, left over after the removal of the kernels during the processing of corn. In countries like the United States, Brazil, and India, corn cobs are typically available in large quantities as a by-product of both commercial agriculture and smaller farming operations.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

During corn processing, the cobs are often separated after threshing, leaving behind a durable, fibrous material. This by-product has multiple applications, from being a raw material for bioethanol production to its use in the creation of biochar and as a feedstock for power generation through combustion. Corn cobs can also be converted into activated carbon, used in filtration systems, or as a substrate for mushroom cultivation.

With the extensive cultivation of corn, corn cobs represent a significant untapped resource that can be efficiently utilized in a variety of sectors, offering an economical and sustainable alternative to conventional raw materials. Let us look into the price, availability, and proximate analysis of corn cob briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Total Corn Cob Generation in India

Corn cobs have a surplus availability of 15 million tonnes annually. This indicates that most of the residue generated is available for energy or other uses, after accounting for current alternative demands.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of maize (corn) reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Characteristic | Loose Biomass | Briquette Form |

| Gross Calorific Value | 3700 Kcal/kg | |

| Moisture Content | 18-20% | 8-10% |

| Ash Content | 1% | 2-3% |

| Silica Content | Less than 1% | Less than 1% |

| Volatile Matter | 88% | 40-50% |

| Fixed Carbon | 11% | 30-40% |

| Bulk Density | 250-300 Kg/m3 | 650-700 Kg/m3 |

| Price | ₹3-3.5 per kg | ₹6.25 per kg |

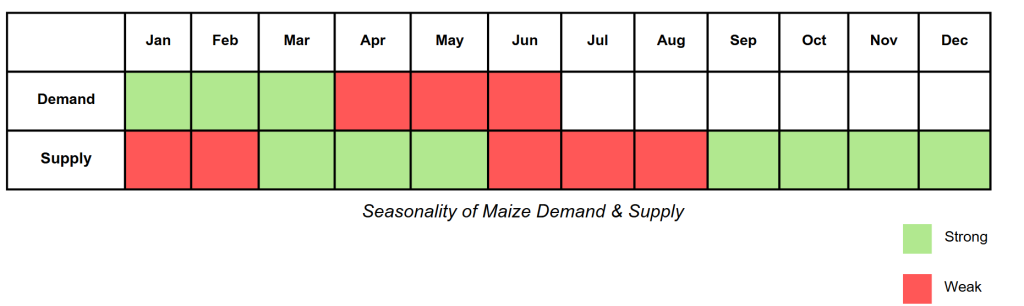

Seasonality

- Kharif season is main growing season in northern India. In the south, however maize is sown any time from April to October.

- Kharif maize represents around 83% of maize area in India, while rabi maize correspond to 17% maize area. Over 70% of kharif maize area is grown under the rainfed condition with a prevalence of many biotic and abiotic stresses.

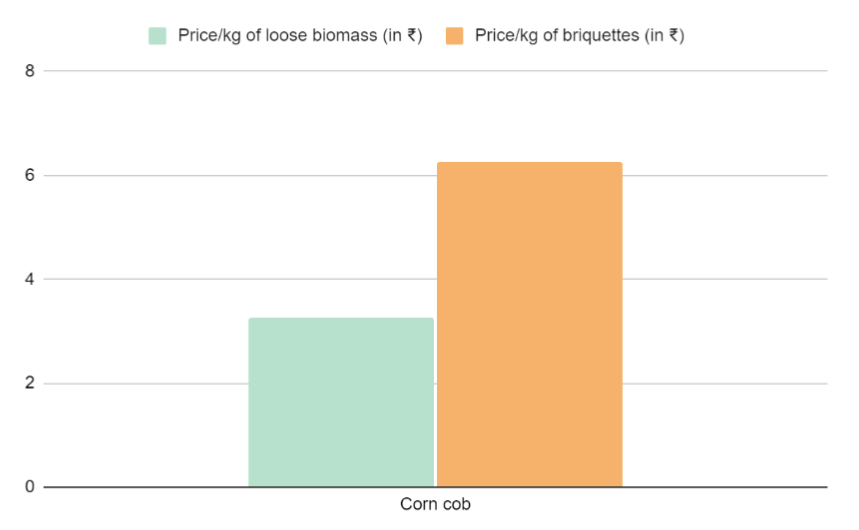

Prices

The price of corn cob biomass in its raw form typically ranges from ₹3 to ₹3.5 per kilogram, making it a moderately priced biomass feedstock in comparison to other alternatives. It costs ₹6.25 per kilogram in briquette form. Fluctuations in loose maize biomass price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

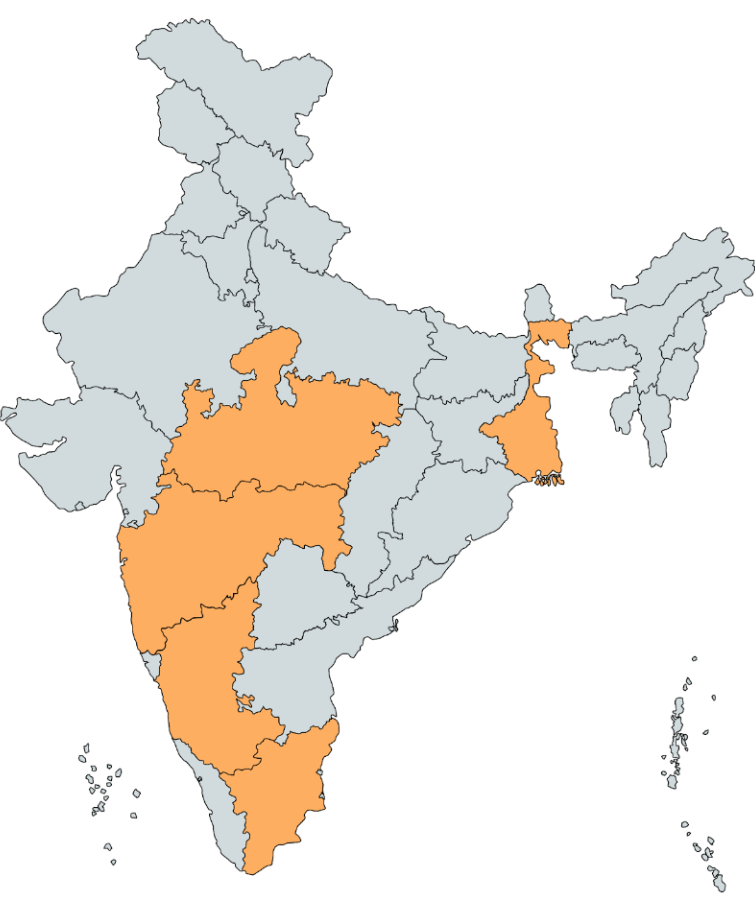

Regional Availability

Regions with abundant maize availability can leverage this resource for use in boilers, promoting sustainable energy practices. The following are the top five states in India where maize/corn cobs are abundantly available, along with key regions within those states:

| State | Total Crop Production in MTPA | Total Corn Cob Generation (MTPA) | Key Regions |

| Karnataka | 5 | 2.3 | Shimoga, Davangere, Chitradurga |

| Madhya Pradesh | 4.5 | 2.07 | Chhindwara, Seoni, Betul, Barwani, Dhar |

| Maharashtra | 3.5 | 1.6 | Siddipet, Kolhapur, Satara, Pune |

| Tamilnadu | 2.8 | 1.3 | Salem, Dindigul, Namakkal, Pudukottai, Tiruppur, Villuppuram, Perambalur, Ariyalur |

| West Bengal | 2.6 | 1.2 | Nadia, Malda, Murshidabad, South Dinajpur, Darjeeling |

Uses of Corn Cob

Current Uses

- Corn Milk Production: Whole ears, including cobs, are used to make corn milk, a flavorful dairy alternative.

- Animal Bedding: Cobs absorb moisture, providing a soft, compliant surface for animal comfort.

- Absorbent: Used as an absorbent in specific industries

Emerging Uses

- Diluent/Carrier Material: Cobs act as fillers in animal health products and agro-chemicals, ensuring even distribution.

- Stock Flavouring: Corn cobs flavour stocks, enhancing the taste of soups and broths.

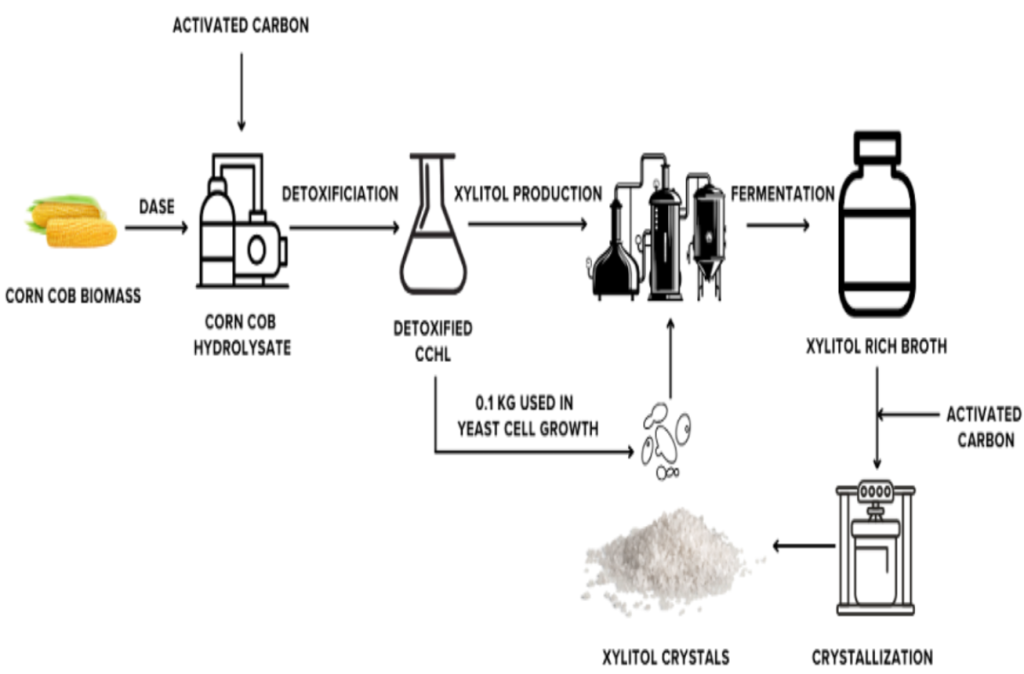

- Xylitol Production: Cobs are a source of xylose, a diabetic-friendly anatural sugar alcohol found in plants, including many fruits and vegetables.

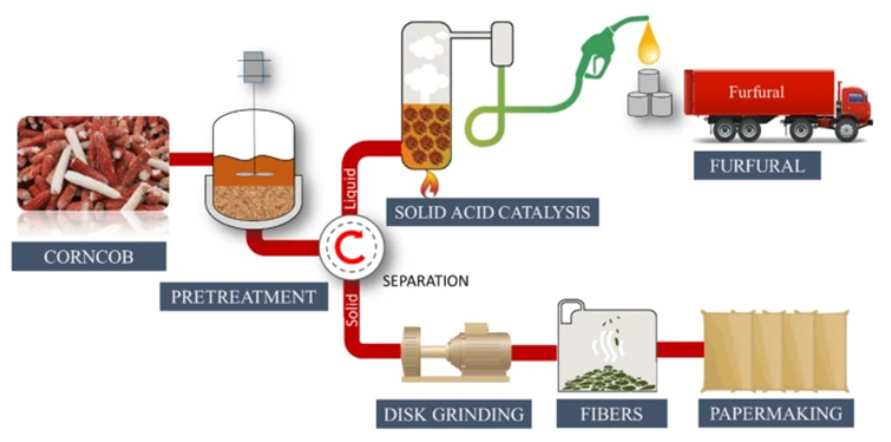

- Furfural Production: Cobs are an industrial source of furfural, a chemical used in various manufacturing processes.

Storage of Corn Cob

- Proper storage ensures that briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

- Moisture Content: The ideal moisture content for storing corn cob feedstock is less than 15%. Above this, there is a higher risk of mold and spoilage.

- Storage Methods:

- Open-air storage: In many rural areas, corn cobs are sun-dried and stored in open fields or under simple covers. However, this method can lead to up to 30% post-harvest losses due to exposure to rain and pests.

- Silo storage: More modern storage involves silos, where the moisture content is strictly controlled. Silos reduce losses significantly but are more expensive.

- Duration: With proper drying, corn cobs can be stored for up to 6-12 months without significant deterioration in quality, especially when stored in sealed containers or silos.

- Storage Capacity: India’s current infrastructure for storing agricultural produce, including corn cobs, faces challenges. For example, the total food grain production in India is about 311 million tonnes (mt), but the storage capacity is only 145 mt. Also, the storage for non-grain biomass feedstock like corn cobs is still underdeveloped.

- Temperature and Humidity: Ideal storage conditions involve temperatures below 25°C and relative humidity under 60% to prevent fungal growth and insect infestations.

Corn Cob as Feedstock – Key Challenges

- Seasonal Availability: Corn cobs are highly seasonal, with a harvesting period concentrated in specific months. India produced around 33 million tonnes of maize in 2022, but supply becomes irregular outside the harvest window.

- Collection and Transportation: Fragmented smallholder farms make collection difficult. A typical Indian maize farm averages 1.15 hectares, leading to logistical challenges in gathering and transporting cobs to processing units.

- Storage Issues: Lack of adequate storage facilities for cobs leads to losses due to moisture and pests. Post-harvest losses in maize can reach up to 10-15% due to poor infrastructure.

- Low Farmer Awareness: Farmers are less aware of the economic potential of corn cob as a feedstock for bioenergy or biochemicals, limiting large-scale collection and usage.

Corn Cobs for Industrial Heating and Power Generation

Uses of Corn Cobs for Industrial Heating and Power Generation

Corn cobs are a valuable biofuel resource due to their high calorific value and abundant availability. They are primarily utilized in two key areas:

- Industrial Heating: Many industries, including food processing, textiles, and paper manufacturing, require substantial heat for their operations. Corn cobs are increasingly being used in boilers to generate the required heat. They burn efficiently, producing a significant amount of energy that can be harnessed for various industrial processes.

- Power Generation: In addition to heating, corn cobs are utilized in small to medium-scale power plants. These plants use the energy produced from burning corn cobs to generate electricity, which can either be used onsite or fed back into the local grid. This form of energy generation is particularly valuable in rural or semi-urban areas, where access to reliable power can be challenging.

Form in Which Corn Cobs are Used in Industries

Industries use corn cobs in several forms to optimize their heating and power generation processes:

- Whole Corn Cobs: In some cases, corn cobs are used as a whole. This form is ideal for larger boilers with grates capable of handling unprocessed cobs.

- Chipped or Shredded: To increase combustion efficiency, industries often use chipped or shredded corn cobs. This reduces the size, increasing the surface area exposed to heat, leading to a more efficient burn.

- Pellets: Corn cob pellets are gaining popularity due to their convenience. These pellets are compact, have a uniform shape, and are easy to transport and store. They burn efficiently, providing consistent energy output, making them a preferred choice for many industries.

Boilers Using Corn Cobs

Boilers are a critical component in utilizing corn cobs for industrial heating. In India, several types of boilers are engineered to burn biomass, including corn cobs:

- Grate Boilers: These are the most common types used for burning solid biomass like corn cobs. They can handle larger biomass chunks, such as whole corn cobs or chipped cobs, making them versatile.

- Fluidized Bed Boilers: These boilers are designed to improve combustion efficiency by suspending solid fuels in a high-pressure air stream, enhancing the contact between the fuel and the air. This is especially useful for chipped or shredded corn cobs, ensuring thorough and efficient combustion.

- Pellet Boilers: Tailored specifically for pelletized fuels, these boilers are popular among industries using corn cob pellets. They offer automated feeding systems, ensuring a steady fuel supply and efficient combustion.

Interesting Fact: Biomass boilers using corn cobs can achieve thermal efficiency levels of 70-85%, depending on the boiler type and fuel form, making them a competitive alternative to traditional fossil-fuel-based heating systems.

Amount of Corn Cobs Being Used by Industries for Industrial Heating

According to recent estimates, India produces about 33 million tonnes of corn annually, generating around 15 million tonnes of corn cobs as agricultural residue. Of this, a significant portion is being utilized in industrial applications for heating and power generation.

Interesting Fact: Utilizing 1 tonne of corn cobs can replace about 0.7-0.8 tonnes of coal, significantly reducing greenhouse gas emissions. This makes corn cobs not only a renewable energy source but also an effective tool for combating climate change.

Prominent Industries Using Corn Cobs for Industrial Heating

Several Indian industries have embraced corn cobs as a sustainable energy solution. Some of the key players include:

- Food Processing: Companies in the food processing sector are using corn cobs to generate heat for drying, cooking, and sterilization processes. The reduced operational costs and stable heat output make corn cobs a preferred choice.

- Textile Industry: The textile industry relies heavily on steam and heat for dyeing, drying, and treating fabrics. Corn cob-fired boilers have become a sustainable energy alternative, helping companies cut down on coal or diesel usage.

- Paper and Pulp: In the paper and pulp sector, corn cobs are utilized to generate steam required for pulping and drying processes. The switch to biomass has resulted in reduced emissions and lower fuel costs.

- Agro-Processing: In agro-processing, particularly in regions with high corn cultivation, corn cobs are locally sourced and used for heating, making them an economically feasible choice for agro-based industries.

- Small-Scale Power Plants: In states like Karnataka and Maharashtra, small-scale power plants run on biomass, including corn cobs, to provide electricity to rural areas and agro-industries.

Interesting Fact: In regions like Punjab and Maharashtra, local cooperatives have started using corn cobs for their power needs, boosting local economies and providing farmers with an additional income stream from selling corn residues.