Key Questions Answered in this Section

- What is Prosopis juliflora (Juliflora), and why is it considered a valuable biomass feedstock?

- How much Juliflora biomass is generated annually in India, and where is it primarily available?

- What are the characteristics of Juliflora biomass in loose and briquette forms?

- How is Juliflora used for industrial heating and power generation in India?

- What forms of Juliflora residues are utilized in industries, such as wood chips, pellets, or briquettes?

- Which industries in India are adopting Juliflora biomass for heating and power applications?

- What are the primary challenges in harvesting, transporting, and storing Juliflora biomass?

- How do boilers like fixed-bed, fluidized-bed, and stoker boilers handle Juliflora residues?

- What are the environmental and economic benefits of using Juliflora biomass as an alternative to coal and diesel?

- How does Juliflora contribute to rural power generation and renewable energy targets in India?

- How is the price of Juliflora biomass in loose form determined, and what factors influence the cost in India?

- How is the price of Juliflora biomass in briquette form determined, and what factors influence its cost?

- Is it possible to directly use Juliflora in boilers?

Introduction

Prosopis juliflora, commonly known as Mesquite, is a fast-growing, drought-resistant shrub or small tree, ideal for biomass feedstock. The primary parts used as biomass feedstock include the wood, branches, leaves, and seed pods, which are rich in lignocellulosic material. These residues are suitable for bioenergy production, including biofuels, charcoal, and biogas. The adaptability of Prosopis juliflora to arid and semi-arid regions makes it a sustainable and low-cost option for renewable energy, especially in areas with limited water resources.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Let us look into the price, availability, and proximate analysis of juliflora briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Total Surplus Generation in India

- Around 1 million tonnes of Juliflora wood is available as surplus biomass in India annually. This amount is considered sufficient for fuel purposes, though harvesting challenges due to the thorny nature of the plant can restrict easy access. Assessing the availability of juliflora involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of juliflora reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Parameter | Loose Form | Briquette Form |

| Gross Calorific Value (GCV) | —– | 4100 kcal/kg |

| Moisture Content | 10% | 7% |

| Ash Content | 1.50% | 2% |

| Silica Content | 1% | 1% |

| Volatile Matter | 80% | 76% |

| Fixed Carbon | 13% | 14% |

| Bulk Density | 407 Kg/m3 | 750 Kg/m3 |

| Price | ₹3-4/kg | ₹7.5/kg |

Seasonality

Juliflora wood is available year-round. While there are minor fluctuations in availability, it is not as heavily affected by seasonal cycles as agricultural residues. However, harvesting and logistics could be a challenge due to the thorny nature of the plant, affecting accessibility in certain seasons.

Regional Availability

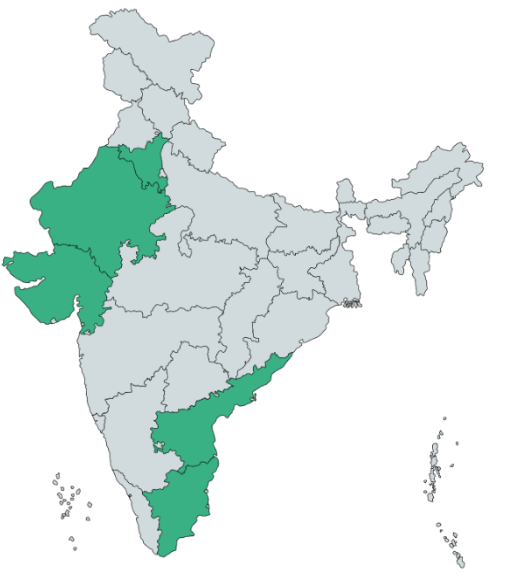

Regions with abundant juliflora availability can leverage this resource for use in boilers, promoting sustainable energy practices.The following are the top 5 states in the distribution of Prosopis juliflora in India:

| States | Key Regions |

| Rajasthan | Barmer, Pali, Jodhpur (almost all districts) |

| Gujarat | Kutch, Banni (almost all districts) |

| Tamil Nadu | Virudhunagar, Sivagangai, Thoothukudi, Ramanathapuram, Tirunelveli |

| Andhra Pradesh | Nellore |

| Haryana | Daya, Kharkada (almost all districts) |

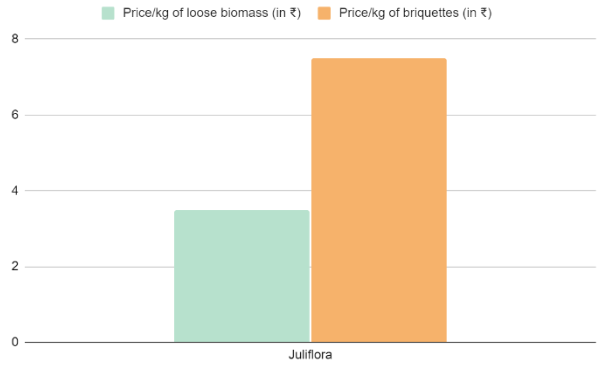

Prices

- Price for raw biomass: ₹3-4 per kg

- Price for briquettes: ₹7.5 per kg

- The cost of Juliflora is moderate compared to other biomass sources, but its price includes cutting and transport as it lacks an organized supply chain, which adds to logistical challenges. Fluctuations in juliflora price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

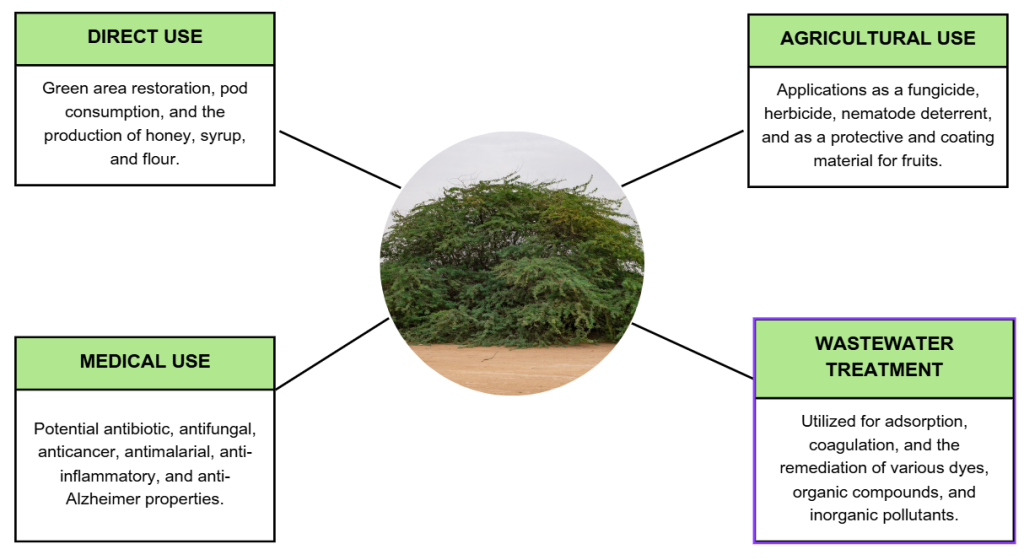

Uses of Juliflora

Current Uses

- Fuelwood and Charcoal Production: Used extensively as firewood and for high-quality charcoal due to its high calorific value.

- Building Material: Durable wood is used for making fences, poles, and simple shelters.

- Tannin Extraction: Bark tannins are extracted for use in leather tanning.

Emerging Uses

- Phytoremediation: Applied in environmental cleanup processes to extract and immobilise heavy metals from polluted soils.

- Medicinal Uses: Extracts used in traditional medicine for treating various ailments, including respiratory and skin conditions.

- Biopesticides: Phytochemicals from Juliflora are used as natural biopesticides, offering an alternative to chemical pesticides.

Storage of Juliflora Biomass

- Moisture Content: Ideal storage requires maintaining moisture levels below 10-15% for optimal energy yield. Juliflora typically has 30-40% moisture when freshly harvested, requiring drying.

- Storage Methods: Open-air drying is commonly used in India, but under controlled conditions, stack and shelter methods protect from rain and reduce moisture. Covered storage is recommended during the monsoon season.

- Duration: Storing Juliflora for more than 6 months can result in dry matter loss of up to 20%. Prolonged storage needs protection from termites and fungal decay, especially in humid areas.

- Space Requirements: Storage density for Juliflora is around 400 kg/m³ for loose wood. Pelletized forms require significantly less space (700-750 kg/m³), ideal for long-term storage.

- Location: Proximity to biomass plants reduces transportation costs, often around ₹500–₹1,000/tonne for distances within 50-100 km.

- Proper storage ensures that juliflora briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Juliflora as Feedstock – Key Challenges:

- Invasive Species: Juliflora is considered an invasive species in many parts of India, particularly in arid and semi-arid regions like Tamil Nadu, Gujarat, and Rajasthan. It threatens local biodiversity by overtaking native vegetation..

- High Moisture Content: Freshly harvested Juliflora wood has a moisture content of 30-50%, which increases the cost and complexity of drying processes before use in energy production.

- Logistics and Transportation: Due to its low bulk density transportation costs are high, especially for large-scale energy plants.

- Harvesting Challenges: Juliflora trees have thorny branches and irregular shapes, making mechanized harvesting difficult and labor-intensive.

Juliflora Residues For Industrial Heating and Power Generation

Uses of Juliflora Residues for Industrial Heating and Power Generation

Juliflora residues—comprising branches, twigs, and other plant parts—are emerging as a valuable biomass resource. In India, these residues are primarily used in the following ways:

- Industrial Heating: Factories use Juliflora residues as a biofuel in boilers to generate heat for various industrial processes, including drying, steaming, and baking. It’s an excellent alternative to conventional fuels like coal and diesel, offering a cleaner and often cheaper energy source.

- Power Generation: Some biomass power plants burn Juliflora residues to produce electricity. These residues serve as a low-cost, sustainable alternative to fossil fuels, helping India inch closer to its renewable energy targets.

- Cogeneration: Many industries have embraced cogeneration (combined heat and power) using Juliflora biomass, maximizing energy efficiency by producing heat and electricity simultaneously.

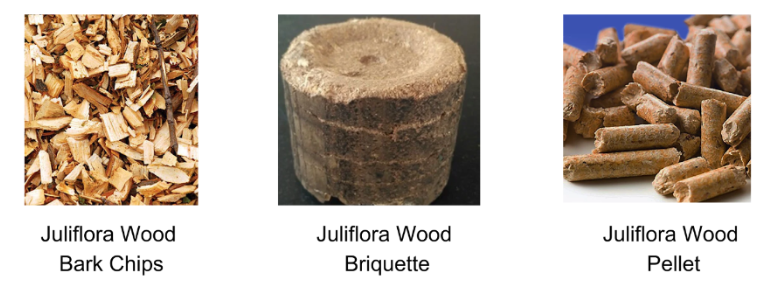

Form in which Juliflora Residues are Used in Industries

Juliflora residues undergo minimal processing before they are used in industrial settings. The common forms include:

- Wood Chips: The residues are shredded into small wood chips, which are ideal for direct combustion in industrial boilers and furnaces. This form is particularly popular in agro-processing and textile industries, where consistent heating is crucial.

- Pellets: In some cases, Juliflora residues are compressed into pellets to create a denser and more uniform biofuel. Pellets are efficient to transport and offer more consistent combustion, making them suitable for modern biomass boilers.

- Briquettes: The residues can also be compressed into briquettes, which are similar to charcoal blocks. Briquettes are an excellent choice for industrial kilns and larger-scale heating operations, as they burn slowly and generate steady heat.

Boilers Using Juliflora Residues

Several types of boilers in India are designed or retrofitted to burn Juliflora residues efficiently:

- Fixed Bed Boilers: These boilers use a stationary bed of Juliflora biomass. Air passes through the bed, allowing controlled combustion, making it suitable for industries requiring consistent heating, like textiles and food processing.

- Fluidized Bed Boilers: In this system, Juliflora residues are burned in a suspended state, enabling better heat transfer and combustion efficiency. These boilers are ideal for power generation and industries with high heat demands.

- Stoker Boilers: Utilizing a mechanical grate, stoker boilers burn wood chips or briquettes from Juliflora residues. The robust design makes them popular in industries like cement and pulp & paper, where high temperatures are essential.

Amount of Juliflora Residues Being Used by Industries for Industrial Heating

Data indicates that the usage of Juliflora residues in India has seen a steady rise:

- India’s Biomass Market Size: The overall biomass market in India is valued at approximately $10 billion, with Juliflora contributing around 8-10% of this sector.

- Rural Power Plants: In Tamil Nadu alone, rural power plants utilizing Juliflora residues generate around 500 MW of electricity annually—a figure that is expected to increase as more plants transition to biomass.

Prominent Industries Using Juliflora Residues for Industrial Heating

Several Indian industries have adopted Juliflora residues due to their cost-effectiveness and eco-friendly nature:

- Textile Industry: Tamil Nadu and Gujarat, the textile powerhouses of India, are turning to biomass boilers using Juliflora residues to generate the steam required in dyeing and fabric processing. This shift has reduced reliance on diesel by nearly 30%.

- Cement Manufacturing: In Rajasthan and Andhra Pradesh, cement manufacturers are using Juliflora as a substitute for coal. This switch is not only lowering carbon emissions but also cutting down energy costs by 15-20%.

- Food Processing: Factories in Maharashtra and Uttar Pradesh are leveraging Juliflora residues for steam generation in food processing. Using biomass has reduced operational costs by about 25%, especially in rice and sugar mills.

- Pulp and Paper Industry: Major players in Odisha and Madhya Pradesh are incorporating Juliflora biomass for both heating and electricity generation, significantly lowering their carbon footprint.

- Power Generation: Several states, including Karnataka and Gujarat, have biomass power plants dedicated to burning Juliflora residues, contributing to decentralized rural electrification.