Key Questions Answered in this Section

- What is the annual production of coffee husk biomass in India, and which regions contribute most significantly to its availability?

- How does the calorific value of coffee husk compare to other agricultural residues commonly used for industrial heating and power generation?

- What are the main challenges associated with using coffee husk as a biomass feedstock, such as high ash content or anti-nutritional compounds, and how can these be mitigated?

- What forms of coffee husk (e.g., raw, briquettes, pellets) are most widely used in industries, and what advantages do these forms offer?

- Which industries in India are the largest consumers of coffee husk for industrial heating and energy generation?

- What are the environmental benefits of using coffee husk as a renewable energy source compared to traditional fossil fuels?

- How does seasonality affect the supply chain of coffee husk, and what strategies can industries adopt to ensure a consistent feedstock supply?

- What advancements in boiler technology (e.g., fluidized bed boilers, multi-fuel boilers) are enhancing the efficiency of burning coffee husk for energy?

- How is coffee husk being used in emerging applications such as biodegradable packaging, activated carbon production, and biochar generation?

- What incentives or policies are in place to promote the use of coffee husk and similar agricultural residues in India’s renewable energy sector?

- How is the price of coffee husk in loose form and as briquettes determined, and what factors influence its cost?

- Is it possible to directly use coffee husk in boilers?

Introduction

Coffee husk is an agricultural byproduct derived from the outer layers of coffee cherries during the processing of coffee beans. As a form of biomass, coffee husks are rich in cellulose, hemicellulose, and lignin, making them an efficient fuel source for energy generation. They also contain around 0.5-2% nitrogen, which can be beneficial for soil when used as fertilizer or compost.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Coffee husks can be utilized in various forms, including direct combustion for heat, briquettes, pellets, and biochar. Their use helps reduce environmental waste and provides a renewable energy source, especially valuable in coffee-producing regions. However, they have high ash content, which can affect combustion efficiency, and they emit some pollutants if not processed correctly.

Let us look into the price, availability, and proximate analysis of coriander stalk briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Total Coffee Husk Generation in India

India produces around 3.5 lakh tonnes of coffee annually. Coffee husk surplus availability is about 0.2 million tonnes per annum. Assessing the availability of coriander stalk involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of coriander stalk reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Parameter | Loose Form | Briquette Form |

| Gross Calorific Value (GCV) | 3745 Kcal/kg | 4300 Kcal/kg |

| Moisture Content | 10% | 10% |

| Ash Content | 5% | 6% |

| Silica Content | 2-5% | 2-5% |

| Volatile Matter | 65-72% | 70% |

| Fixed Carbon | 17-20% | 20% |

| Bulk Density | 260 Kg/m3 | 800-850Kg/m3 |

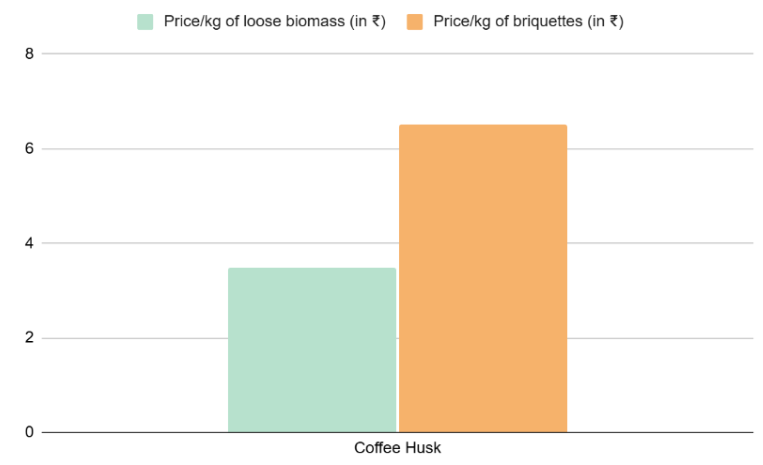

| Price | ₹3-4/Kg | ₹6-7/Kg |

Seasonality

In India, the seasonality of coffee revolves around its flowering, planting, and harvesting periods, influenced by monsoon patterns:

Flowering:

- Blossom Shower:

- Robusta: February to March

- Arabica: March to April

- Backing Shower (for both Arabica and Robusta): Required in April to May to support flower setting.

Planting:

- Planting Season: Stretches from June to December, allowing seedlings to establish before the monsoon.

Harvesting:

- Harvesting Period: Primarily between November and February when berries ripen.

- Fly Picking: Early picking starts in October and may continue intermittently through February for selectively ripe berries.

- Main Picking: Major harvesting is done in December for fully ripened berries.

- Stripping: Final picking occurs in February, collecting any remaining berries regardless of ripeness.

- Cleanings: Collection of fallen berries during the harvest season.

| Stage | Variety | Timing | Details |

| Flowering | Robusta | February – March | Requires “blossom shower” for flower initiation. |

| Arabica | March – April | Needs blossom shower for effective flower setting. | |

| Backing Shower | Both Varieties | April – May | Essential to support flower setting after the initial blossom. |

| Planting | Both Varieties | June – December | Planting season to establish seedlings before monsoon season. |

| Harvesting | Both Varieties | November – February | Collection of ripe coffee berries across different picking phases. |

| Fly Picking | Both Varieties | October – February | Early picking of selectively ripe berries. |

| Main Picking | Both Varieties | December | Bulk harvest of well-ripened berries. |

| Stripping | Both Varieties | February | Final picking of all remaining berries, regardless of ripeness. |

| Cleanings | Both Varieties | Throughout Harvest | Collection of dropped fruits during the main harvest season. |

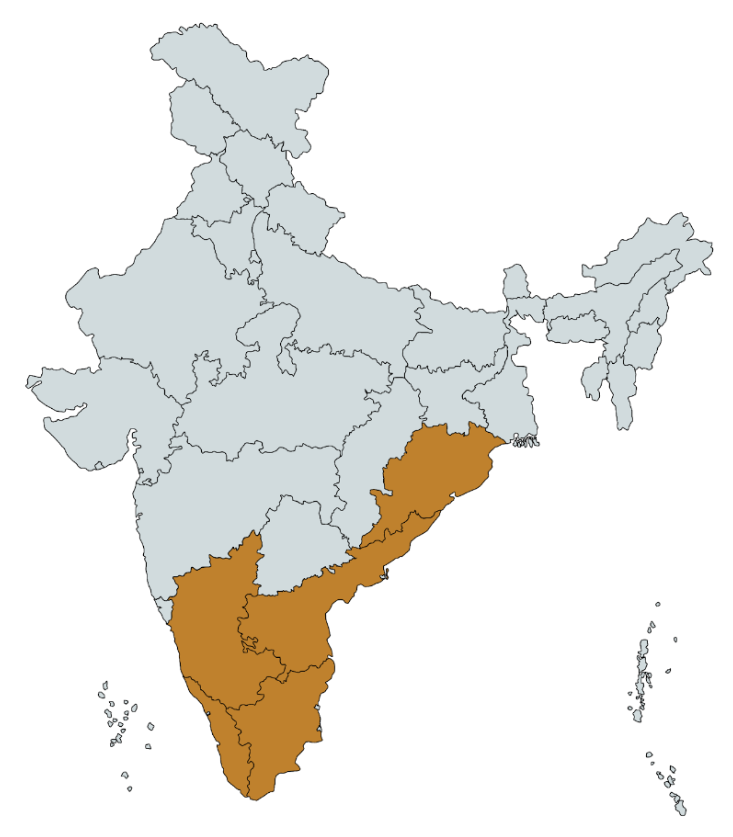

Regional Availability

Regions with abundant coriander stalk availability can leverage this resource for use in boilers, promoting sustainable energy practices. The following are the top 3 states in coffee production

| Rank | State | Annual Production (in tons) | Description |

| 1 | Karnataka | 248,020 | Karnataka is the leading coffee-producing state in India, contributing over 55% of the nation’s total coffee output. The primary coffee-growing regions include the districts of Chikkamagaluru, Hassan, and Kodagu. |

| 2 | Kerala | 72,425 | Kerala ranks second in coffee production within India, with significant contributions from Idukki, Kollam, and Pathanamthitta, producing around 72,425 tons annually. |

| 3 | Tamil Nadu | 18,700 | Tamil Nadu stands third, recognized for its premium Arabica varieties, predominantly grown in the districts of Coimbatore, Dindigul, and The Nilgiris, yielding an estimated 18,700 tons each year. |

| 4 | Andhra Pradesh | 12,265 | Coffee is grown in the agency areas of Chintapalli, Gudem, Paderu and Maredumilli of Visakhapatnam and East Godavari Districts in Andhra Pradesh. |

| 5 | Odisha | 465 | Koraput, Rayagada, Gajapati, Kalahandi, Kandhamal and Keonjhar |

Prices

- Loose Biomass: Raw husks are being sold for ₹3-4/kg

- Briquettes: The briquette form of coffee husks costs around ₹6-7/kg, making it one of the cheapest feedstocks

- Fluctuations in coriander stalk price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

Uses of Coffee Husk

Current Uses

- Biofuel Production: Coffee husks are commonly used in producing bioethanol, bio-oil, and biochar. The high lignin and cellulose content make coffee husks an excellent feedstock for biofuel production, offering an eco-friendly alternative to fossil fuels.

- Compost and Organic Fertilizer: Coffee husks are composted or directly used as organic fertilizer. Their nutrient profile, rich in potassium, nitrogen, and phosphorous, enhances soil fertility and structure, supporting sustainable agricultural practices.

- Livestock Feed Supplement: Coffee husk biomass is often processed into feed for cattle and poultry. When treated to reduce caffeine and anti-nutritional factors, coffee husk provides a fiber-rich supplement for livestock, especially in regions with limited feed resources.

Emerging Uses

- Biodegradable Packaging Material: Coffee husks are being developed into biodegradable packaging solutions as part of the push for sustainable alternatives to plastics. They are molded and processed into plates, cups, and packaging materials with impressive durability.

- Activated Carbon for Water Filtration: Researchers are exploring coffee husk biomass as a source for producing activated carbon, an efficient material for water and air filtration. Its porous structure and high surface area make it effective for adsorbing impurities and pollutants.

- Textile Dye Production: Coffee husks are showing promise as a natural dye source for textiles. The polyphenolic compounds present can be extracted to create eco-friendly, non-toxic dyes, offering sustainable alternatives for the textile industry.

Storage of Coffee Husk

- Moisture Control: Coffee husks should be stored in a dry, well-ventilated area to prevent moisture buildup. High moisture levels can lead to mold growth and fermentation, compromising the quality and usability of the husks for applications like biofuel and animal feed.

- Temperature Management: Keep storage areas cool, ideally below 25°C, as higher temperatures can accelerate the degradation of husk material, reduce its calorific value, and encourage microbial activity.

- Protection from Pests: Coffee husks are prone to attracting pests, such as rodents and insects. Sealed containers or lined storage bags with pest control measures, such as natural repellents, are essential to preserve husk integrity.

- Stacking and Aeration: To prevent compaction and allow for proper aeration, store coffee husks in loose stacks or bags, with adequate spacing between them. This helps prevent overheating and further microbial growth, which can deteriorate husk quality.

- Proper storage ensures that coriander stalk briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Coffee Husk as Feedstock – Key Challenges

- High Moisture and Ash Content: Coffee husks often have a high initial moisture content (up to 10-12%) and significant ash levels, which can hinder efficient combustion and reduce energy yield. Pre-drying and ash removal processes add extra costs and complexity to their use as a biomass fuel source.

- Presence of Anti-Nutritional Compounds: Coffee husks contain compounds like caffeine and tannins, which are toxic in high doses and can limit their application in livestock feed or compost. Special treatments, such as fermentation or leaching, are necessary to neutralize these compounds, increasing processing requirements.

- Risk of Self-Heating and Spontaneous Combustion: Due to residual oils and volatile organic compounds, coffee husk biomass is prone to self-heating, especially in bulk storage, leading to potential fire hazards. Controlled storage conditions with temperature monitoring are essential but add logistical challenges.

- Inconsistent Quality and Supply Chain Issues: The quality of coffee husk biomass can vary based on factors like origin, processing methods, and harvest conditions, resulting in inconsistent energy density and chemical composition. Additionally, coffee husks are often available seasonally, posing challenges for a steady, year-round supply chain.

Coffee Husk for Industrial Heating and Power Generation

Uses of Coffee Husk for Industrial Heating and Power Generation

Coffee husk, comprising approximately 30% of the coffee cherry’s weight, is a rich source of biomass energy. It can be converted into heat and electricity through various methods, contributing to both direct heating applications and energy generation. Some primary uses include:

- Boiler Fuel: Coffee husk can be directly used as a fuel in biomass boilers, providing a renewable source of energy for industrial processes.

- Energy Generation: Coffee husk can be converted into pellets or briquettes, which are then used in combined heat and power (CHP) systems to generate electricity while producing heat as a byproduct.

- Heat Generation: Many industries utilize coffee husk in furnaces or kilns for direct heating applications, such as drying processes in the food industry.

- Biochar Production: Through pyrolysis, coffee husk can be transformed into biochar, which is not only a valuable soil amendment but can also be used as a solid fuel for energy generation.

Form in Which Coffee Husk is Used in Industries

Industries typically utilize coffee husk in several forms to maximize its energy potential:

- Raw Husk: Used directly as fuel in traditional boilers and furnaces, particularly in the food processing and agro-based industries.

- Briquettes and Pellets: Compressed forms that are easier to transport and store, ideal for use in automated heating systems and modern biomass boilers.

- Powdered Form: Finely ground coffee husk can be used in specialized applications, such as biomass gasification, where it serves as a feedstock for syngas production.

Boilers Using Coffee Husk

Several types of boilers are designed to efficiently burn coffee husk for energy generation:

- Fluidized Bed Boilers: These boilers are ideal for burning biomass like coffee husk, offering high efficiency and lower emissions due to better combustion control.

- Grate-Fired Boilers: Common in industrial applications, these boilers allow for the direct burning of bulk biomass, including coffee husk, on a grate.

- Multi-Fuel Boilers: Designed to utilize various biomass materials, these boilers can switch between coffee husk and other fuels based on availability and cost.

Amount of Coffee Husk Being Used by Industries for Industrial Heating

The utilization of coffee husk for industrial heating is gradually increasing in India, although specific data can be sparse. However, estimates suggest:

- Around 500,000 tons of coffee husk is used annually for energy generation across various industries.

- Industries that primarily use coffee husk include food processing, textiles, and small-scale bioenergy projects, with the food processing sector being the largest consumer.

Prominent Industries Using Coffee Husk for Industrial Heating

- Food Processing Industry: Companies engaged in roasting coffee beans and processing other food products are the primary users of coffee husk, utilizing it for both direct heating and energy generation.

- Textile Industry: Some textile manufacturers use coffee husk as a biomass fuel source for steam generation and heating processes.

- Power Generation Companies: A few bioenergy firms are investing in biomass power plants, incorporating coffee husk as a sustainable feedstock for electricity production.

- Agro-Processing Units: Facilities processing agricultural products increasingly utilize coffee husk as a renewable energy source, especially in regions where coffee is cultivated.