Key Questions Answered in this Section

- What is the annual production of millet stalk biomass in India, and which regions contribute most significantly to its availability?

- How does the energy potential of millet stalks compare to other agricultural residues commonly used in industrial heating and power generation?

- What forms of millet stalks (e.g., loose, briquettes, pellets) are most commonly used in industrial applications, and what are the advantages of each?

- Which industries in India are the largest consumers of millet stalks for heating and energy production?

- What are the challenges associated with using millet stalks as a biomass feedstock, such as moisture content or transportation costs, and how can they be mitigated?

- How do millet stalks align with India’s renewable energy goals, particularly in reducing dependence on fossil fuels?

- What role do millet stalks play in emerging technologies like biodegradable packaging or biofuel production?

- How does seasonality affect the supply chain of millet stalks, and what strategies can industries adopt to ensure consistent feedstock availability?

- What advancements in boiler technologies are enhancing the efficiency of millet stalk combustion for industrial applications?

- Are there specific government policies or incentives in place to promote the use of millet stalks as a renewable energy resource?

- How is the price of millet stalk in loose form and as briquettes determined, and what factors influence its cost?

- Is it possible to directly use millet stalk in boilers?

Introduction

Millet stalks, the fibrous residue left after harvesting millet grains, have emerged as a promising biomass feedstock for renewable energy and sustainable material production. Known for their high cellulose and hemicellulose content, millet stalks are ideal for producing biofuels, biogas, and biochar. This hardy plant thrives in arid regions with minimal water, making it an eco-friendly choice that doesn’t compete with food resources. Beyond energy, millet stalks are used to create biodegradable plastics and compost, offering a full-cycle solution that benefits both energy and agriculture sectors.

Let us look into the price, availability, and proximate analysis of coffee husk briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Total Millet Generation in India

India produces around 15-16 million metric tonnes of millets annually, making it one of the largest producers globally. The production includes various types of millets, such as:

| Millet Type | Total Crop Production (in MTPA) | Primary States of Cultivation |

| Pearl Millet (Bajra) | 9.5 | Rajasthan, Maharashtra, Gujarat, Uttar Pradesh |

| Sorghum (Jowar) | 4.5 | Maharashtra, Karnataka |

| Finger Millet (Ragi) | 1.6 | Karnataka, Tamil Nadu, Odisha |

| Small Millets | 0.35 | Various regions; includes states growing foxtail, barnyard, and kodo millet |

The promotion of millets as “Nutri-cereals” by the Indian government has increased their popularity, leading to better yields and more emphasis on millet-based agriculture, particularly under initiatives like the National Food Security Mission (NFSM).

Seasonality

Known for its drought tolerance, Bajra thrives in warm, dry climates with low annual rainfall, making it a versatile crop suited for varied agricultural practices across India.

| State | Season | Planting Time |

| Rajasthan | Summer | February-May |

| Uttar Pradesh | Summer | February-May |

| Gujarat | Summer | February-May |

| Rabi | November-February | |

| Maharashtra | Rabi | November-February |

| Tamil Nadu | Summer | January-February (for high yield) |

| Rabi | October (first fortnight) | |

| Punjab | Summer | March-June |

Regional Availability

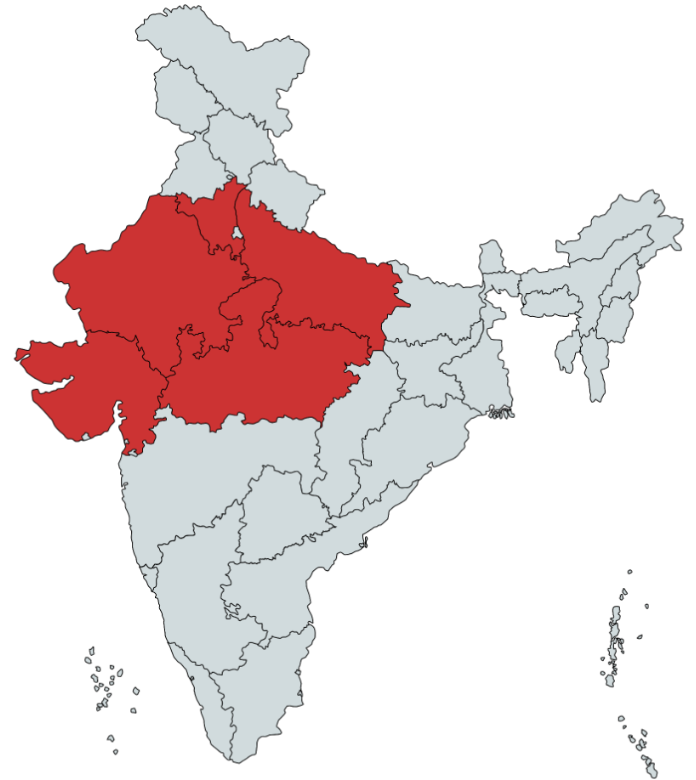

Regions with abundant coffee husk availability can leverage this resource for use in boilers, promoting sustainable energy practices. Here are the top 5 regions in bajra production in India:

| State | Total Bajra Production (in MTPA) | Key Regions of State |

| Rajasthan | 3.75 | Alwar, Jaipur, Jodhpur, Sikar, Nagaur, Barmer, Jaisalmer, Bikaner, Ganganagar, Jhunjhunu, Jalore, Dausa, Karauli, Bharatpur |

| Uttar Pradesh | 1.95 | Western UP, Agra |

| Haryana | 1.1 | Sims, Hisar, Karnal, Kaithal, Kurukshetra, Fatehabad, Bhiwani, Rohtak |

| Gujarat | 1 | Kutch, Banaskantha |

| Madhya Pradesh | 0.9 | Malwa |

Uses of Millet Stalks

Current Uses

- Fodder for Livestock: Millet stalks are widely used as nutritious fodder, providing essential fiber and nutrients for cattle, sheep, and goats, particularly in arid regions.

- Fuel for Cooking: Dried millet stalks serve as a readily available, low-cost biofuel in rural areas, often used in cooking stoves.

- Mulching Material: Farmers commonly use millet stalks for mulching, which helps conserve soil moisture, control weeds, and improve soil fertility.

Emerging Uses

- Bioenergy Production: Millet stalks are being explored as a biomass source for generating biofuels and biogas, promoting renewable energy.

- Biodegradable Packaging: Research is underway on processing millet stalk fibers into eco-friendly packaging materials, reducing reliance on plastics.

- Industrial Fiber Use: Innovations in converting millet stalks into industrial fibers aim to produce sustainable materials for the textile and paper industries.

Storage of Millet Stalks

- Moisture Control: Store stalks in a dry environment with controlled humidity to prevent mold growth and ensure prolonged quality.

- Ventilation: Maintain proper airflow around stored stalks to reduce moisture buildup and prevent fermentation, which can degrade feed quality.

- Stacking Technique: Arrange stalks in an elevated, well-organized stack to avoid ground moisture absorption and rodent access.

- Use of Storage Silos or Barns: For large-scale storage, dedicated silos or barns with protective covers provide optimal preservation, especially during monsoon or humid seasons.

- Proper storage ensures that coffee husk briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Millet Stalks as Feedstock – Key Challenges

- Nutritional Limitations: Millet stalks have lower protein content compared to other feed, which may require supplementation for balanced livestock nutrition.

- Moisture and Mold Issues: High humidity can lead to mold growth in stalk storage, which poses health risks to animals.

- Bulkiness and Transport Costs: Due to their low density, millet stalks are costly and cumbersome to transport over long distances.

- Storage Constraints: Large volumes require significant storage space, especially in areas with limited infrastructure.

- Processing Requirements: Stalks often need chopping or grinding to improve palatability, adding labor and equipment costs.

Millet Stalks for Industrial Heating and Power Generation

Uses of Millet Stalks for Industrial Heating and Power Generation

Millet stalks are increasingly being recognized for their potential in biomass energy production. They are rich in cellulose, making them suitable for combustion and gasification processes.

- Biomass Fuel: Millet stalks are primarily used as biomass fuel in power generation plants. They provide a renewable energy source that reduces reliance on fossil fuels, aligning with India’s commitment to sustainable energy.

- Heating Applications: Various industries utilize millet stalks for heating processes. These include:

- Textile Industry: For steam generation in dyeing and finishing processes.

- Food Processing: Used in boilers for cooking and drying applications.

- Brick Kilns: Millet stalks are employed as a source of energy in brick manufacturing, promoting eco-friendly practices.

- Energy Production: The energy potential of millet stalks is substantial. Studies show that they can produce between 3,800 to 4,500 kcal/kg of energy, making them a competitive alternative to conventional fuels.

Form in Which Millet Stalks Are Used in Industries

Millet stalks can be processed and utilized in various forms, depending on the specific industrial requirements:

- Chopped Stalks: Commonly used in biomass boilers, chopped millet stalks are easy to handle and facilitate efficient combustion.

- Pellets: The densification of millet stalks into pellets enhances their combustion efficiency and makes transportation easier. Pellets are particularly advantageous for small to medium-sized boilers.

- Briquettes: These are compact, high-energy fuel blocks made from millet stalks, providing a convenient option for industrial heating.

- Pulp and Fiber: In some applications, the fibrous content of millet stalks is processed into pulp for various industrial uses, including paper and biocomposite materials.

Boilers Using Millet Stalks

The integration of millet stalks into boiler systems has shown promising results in several industries:

- Steam Boilers: Industries such as textiles and food processing utilize steam boilers fueled by millet stalks, offering an efficient means of heat generation while minimizing environmental impact.

- Thermal Power Plants: The use of millet stalks in biomass-based power plants has gained traction, with several installations across India converting agricultural waste into energy. Notable projects include the establishment of biomass power plants in states like Maharashtra and Andhra Pradesh.

- Cogen Plants: Co-generation facilities that produce both electricity and useful heat from millet stalks are becoming popular, providing a dual benefit and improving overall efficiency.

Amount of Millet Stalks Being Used by Industries for Industrial Heating

The use of millet stalks for industrial heating is on the rise, supported by increasing awareness of sustainable practices. Current estimates suggest that approximately 15 million tonnes of millet stalks are produced annually in India. Out of this, around 1.5 million tonnes are being utilized for biomass energy and industrial heating. This number is expected to grow as more industries adopt renewable energy sources.

Interesting Fact:

Did you know that India is one of the largest producers of millet globally, contributing to around 41% of the world’s millet production? This positions the country as a vital player in promoting millet stalks as a resource for industrial applications.

Prominent Industries Using Millet Stalks for Industrial Heating

Several industries have taken the lead in incorporating millet stalks into their energy strategies:

- Textile Industry: Companies like Vardhman Textiles have begun using biomass boilers fueled by millet stalks, significantly reducing their carbon footprint.

- Food Processing: Major food brands, including Britannia and ITC, are exploring biomass energy solutions to enhance sustainability in their manufacturing processes.

- Brick Manufacturing: Numerous brick kilns across states like Uttar Pradesh and Rajasthan are transitioning to biomass fuels, including millet stalks, to minimize environmental impact.

- Power Generation: Biomass power plants, such as those operated by Renewable Energy Limited in Madhya Pradesh, are now utilizing millet stalks to produce green energy, contributing to the nation’s renewable energy goals.