Key Questions Answered in this Section

- What is rice straw, and how is it generated as a byproduct of rice farming?

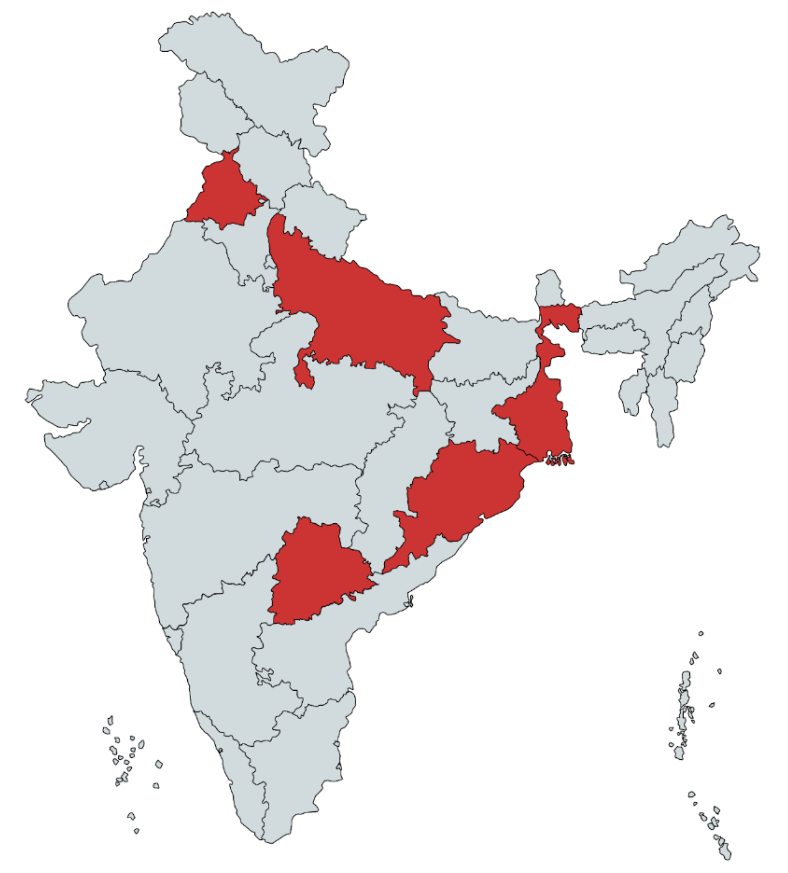

- How much rice straw is produced annually in India, and which states contribute the most?

- What are the key characteristics of rice straw as biomass in loose and briquette forms?

- How is rice straw utilized for industrial heating and power generation in India?

- What forms of rice straw, such as pellets, briquettes, or bales, are commonly used in industries?

- What are the primary challenges in collecting, transporting, and storing rice straw for bioenergy?

- How do boilers like fluidized bed and moving grate systems efficiently utilize rice straw?

- What environmental benefits are associated with using rice straw instead of burning it in fields?

- Which industries in India are adopting rice straw-based biomass boilers, and what are the key advantages?

- How does the use of rice straw for biomass power support India’s renewable energy goals?

- How is the price of rice straw in loose form determined, and what factors influence the cost in India?

- How is the price of rice straw in briquette form determined, and what factors influence the cost?

- Is it possible to directly use rice straw in boilers?

Introduction

Rice straw is the dry stalks left behind after harvesting rice grains. It is an abundant, renewable agricultural residue primarily composed of cellulose, hemicellulose, and lignin. This biomass feedstock is widely available in rice-producing regions and has significant potential for bioenergy production, including biofuels, biogas, and biochar. Utilizing rice straw helps reduce open-field burning, which contributes to air pollution, and provides an eco-friendly alternative for energy generation and bioproducts.

Let us look into the price, availability, and proximate analysis of rice straw briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Total Rice Straw Generation in India

- India generates about 126 million tonnes of rice straw annually.

- This makes rice straw one of the most prominent agricultural residues produced in the country.

- Assessing the availability of rice straw involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of rice straw reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Parameter | Loose Form | Briquette Form |

| Gross Calorific Value (GCV) | —- | 3400 Kcal/kg |

| Moisture Content | 15% | 8-12% |

| Ash Content | 18% | 20% |

| Silica Content | 12% | 10-15% |

| Volatile Matter | 70% | 65% |

| Fixed Carbon | 14% | 16% |

| Bulk Density | 150-200 Kg/m3 | 600-650 Kg/m3 |

| Price | ₹5.5-6/kg | ₹.6-9/kg |

Seasonality

Rice cultivation in India takes place under a wide range of altitudes and climatic conditions, leading to different rice growing seasons across the country. Factors like temperature, rainfall, soil type, and water availability significantly influence the cultivation calendar in various regions. In the eastern and southern parts of India, the temperatures are suitable for rice farming throughout the year, allowing farmers to grow two or even three crops annually. In contrast, in northern and western regions, where winters are cooler and rainfall is substantial, rice is typically grown once a year, from May to November.

Rice cultivation in India can be categorized into three main seasons—autumn, winter, and summer—based on the harvest period. Here’s a breakdown of these seasons:

Autumn Season (Pre-Kharif Rice)

Autumn rice, often referred to as pre-Kharif rice, is sown between May and August, with the harvest occurring in September and October. The specific timing of planting varies by state, depending on local weather and rainfall patterns. The crop goes by different names in different regions: Aus in West Bengal, Ahu in Assam, Beali in Odisha, Bhadai in Bihar, Virippu in Kerala, and Kuruvai/Kar/Sornavari in Tamil Nadu. This season accounts for about 7% of India’s total rice production, with most varieties being short-duration crops that mature in 90 to 110 days.

Winter Season (Kharif Rice)

The primary rice-growing season in India is the Kharif, also known as winter rice due to its harvest period. Sowing generally takes place in June and July, with harvesting from November to December. It goes by various local names, including Aman in West Bengal, Sali in Assam, Sarrad in Odisha, Agahani in Bihar and Uttar Pradesh, Sarava in Andhra Pradesh, Mundakan in Kerala, and Samba/Thaladi in Tamil Nadu. This season is responsible for around 84% of the country’s rice output, with farmers favoring medium to long-duration varieties.

Summer Season (Rabi Rice)

The summer rice crop, known as Rabi rice, is planted between November and February and harvested from March to June. Regional names include Boro in Assam and West Bengal, Dalua in Odisha, Dalwa in Andhra Pradesh, Punja in Kerala, Navarai in Tamil Nadu, and Garma in Bihar. This season covers about 9% of the rice-growing area, with early-maturing varieties being the norm.

Different states have specific planting and harvesting windows for these seasons, influenced by local climate conditions and rainfall.

| SL | Region/State | Autumn Sowing | Autumn Harvesting | Winter Sowing | Winter Harvesting | Summer Sowing | Summer Harvesting |

| 1 | Northern Region | ||||||

| Haryana | – | – | – | – | – | – | |

| Punjab | May-Aug | Sep-Nov | – | – | – | – | |

| West U.P. | – | – | – | – | – | – | |

| Himachal Pradesh | June-July | Sep-Nov | – | – | – | – | |

| Jammu & Kashmir | – | – | Apr-July | Sep-Dec | – | – | |

| 2 | Western Region | ||||||

| Gujarat | – | – | Jun-Aug | Oct-Dec | – | – | |

| Maharashtra | – | – | Jun-July | Oct-Dec | – | – | |

| Rajasthan | – | – | July-Aug | Oct-Dec | – | – | |

| 3 | North-East Region | ||||||

| Assam | Mid Feb-Apr | June-July | June-Aug | Nov-Dec | Dec-Feb | May-June | |

| 4 | Eastern Region | ||||||

| Bihar | May-July | Sep-Oct | July-Sep | Nov-Dec | Jan-Feb | May-June | |

| East M.P. | June-Aug | Mid Sep – Mid Dec | – | – | – | – | |

| Orissa | May-June | Sep-Oct | June-Aug | Dec-Jan | Dec-Jan | May-June | |

| East U.P. | May-July | Sep-Nov | July-Aug | Nov-Dec | Jan-Feb | Apr-June | |

| West Bengal | Mar-June (Broadcasting)May-June (Transplanting) | July-Nov | Apr-June (Broadcasting)July-Aug (Transplanting) | Nov-Dec | Oct-Feb | Apr-May | |

| 5 | Southern Region | ||||||

| Andhra Pradesh | Mar-April | July-Aug | May-June | Nov-Dec | Dec-Jan | April-May | |

| Karnataka | May-Aug | Sep-Dec | June-Oct | Nov-March | Dec-Feb | April-July | |

| Kerala | April-June | Aug-Oct | Sep-Oct | Jan-Feb | Dec-Jan | March-Apr | |

| Tamil Nadu | Early Samba | Late Samba | |||||

| Sonavari | April-May | July-Aug | June-July | Nov-Dec | Oct-Nov | March-Apr | |

| Samba | Navarai | ||||||

| Kar | May-June | Aug-Sep | July-Aug | Dec-Jan | Dec-Jan | April-May | |

| Thaladi/Pishanam | |||||||

| Kuruvai | June-July | Sep-Oct | Sep-Oct | Dec-Jan | – | – | |

Regional Availability

Regions with abundant rice straw availability can leverage this resource for use in boilers, promoting sustainable energy practices. The following are the top five states in India where rice is abundantly available, along with key regions within those states:

| State | Annual Rice Production (MTPA) | Annual Rice Straw Generation (MTPA) | Key Regions of State |

| West Bengal | 16 | 23 | Midnapore, Bardhaman, Dinajpur, South 24 Parganas, Birbhum, Bankura, Murshidabad, Burdwan, Hooghly, Nadia |

| Uttar Pradesh | 15 | 16 | Bijnor, Kushinagar, Pilibhit, Chandauli, Baghpat, Varanasi and Ambedkarnagar |

| Punjab | 13 | 20 | Tehgarh, Sangrur, Ludhiana, Moga, Ferozepur, Bhatinda, Jalandhar, Kapurthala, Nawanshahar, Faridkot, Patiala, Mukatsar, Mansa, Ropar, Amritsar, Hoshiarpur, Gurudaspur |

| Telangana | 12 | 17 | Nalgonda, Suryapet, Nizamabad, Siddipet, Karimnagar, Kamareddy, Yadadri, Khammam, Peddapalli, Rajanna Sircilla, Jangaon |

| Odisha | 9 | 12.5 | Baragarh, Mayurbhanj, Balasore, Bolangir, Ganjam, Kalahandi, Puri, Keonjhar, Bhadrak, Sundergarh |

Prices

- Loose Biomass: The price of loose rice straw typically ranges from ₹5.5-6 per kg

- Briquettes: If processed into briquettes, the price can go up to around ₹6-9 per kg, making it one of the more expensive biomass options.

- Fluctuations in rice straw price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

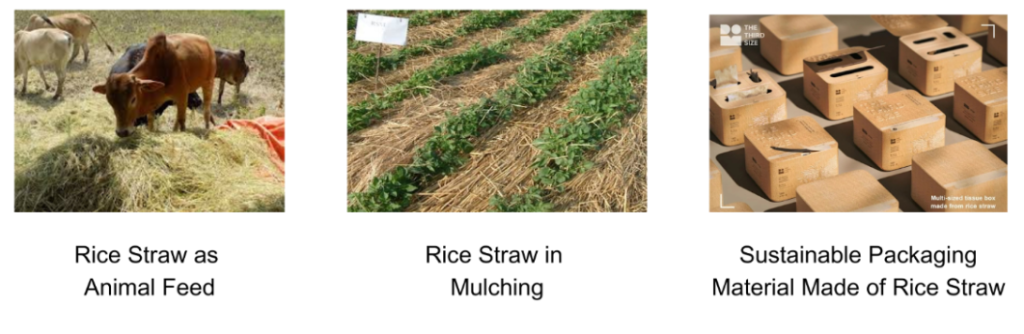

Uses of Rice Straw

- Animal Feed: Rice straw is sometimes used as low-quality animal fodder, although it is not highly preferred due to its poor nutritional content.

- Briquettes and Pellets: While less common, rice straw can be converted into briquettes or pellets for use in energy generation.

- Mulching and Composting: It can be used as a soil cover for mulching or incorporated into compost to enhance soil fertility.

- Paper and Packaging Material: It has potential in the production of bio-based packaging materials and low-grade paper.

Storage of Rice Straw

- Bale Storage: Rice straw is often stored in bales for easier transportation and handling. Storage in bales reduces exposure to air and moisture, which helps preserve its quality.

- Moisture Content: The optimal moisture content for rice straw storage is below 15% to prevent microbial growth, which can lead to spoilage. Higher moisture levels lead to decomposition and mold.

- Storage Structures: In India, rice straw is stored in open fields or thatched sheds to protect it from rain and sun. However, improved methods like silage pits or warehouses with proper ventilation are more effective for long-term storage.

- Storage Duration: Under optimal conditions, rice straw can be stored for up to 12 months. However, poor storage conditions reduce this time due to nutrient degradation.

- Losses: In open storage, 15-20% of the straw can be lost due to weather and pest damage. Proper coverage, like using plastic sheets or elevated platforms, can minimize losses.

- Regional Variations: States like Punjab and Haryana, where rice production is high, have invested in improved storage infrastructure to support straw use in bioenergy plants.

- Proper storage ensures that rice straw briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Rice Straw as Feedstock – Key Challenges

- High Collection Costs: Rice straw is widely dispersed across farmlands, leading to high transportation and collection costs, which account for up to 30-40% of total biomass costs.

- Low Bulk Density: Rice straw has a low bulk density of 40-200 kg/m³, making storage and transportation inefficient. It requires densification, which further increases costs.

- Seasonal Availability: Rice straw is available only post-harvest (October-November), leading to storage challenges for year-round usage. About 120 million tons of rice straw is generated annually, but it is mostly available within a short timeframe.

- Burning Practices: Around 25 million tons of rice straw are burned annually, especially in states like Punjab and Haryana, due to lack of incentives and infrastructure for collection and utilization, contributing to severe air pollution.

- High Silica Content: Rice straw has 15-20% silica, making it less ideal for certain industrial uses like biofuel production due to the abrasive nature and high ash content (up to 20%).

- Lack of Efficient Market Linkages: The market for rice straw as a feedstock for bioenergy, paper, or fodder is still underdeveloped, leading to limited demand and lower farmer incentives to collect and sell it.

- Policy and Infrastructure Gaps: Although there are government initiatives for biomass-based energy, the lack of infrastructure for large-scale processing and collection limits its effective utilization.

Rice Straw for Industrial Heating and Power Generation

Uses of Rice Straw for Industrial Heating and Power Generation

Rice straw is increasingly used in industrial boilers to generate steam and heat for various industrial processes. Key applications include:

- Industrial Heating: Industries use rice straw as a biofuel to produce heat required for manufacturing processes such as drying, steam generation, and chemical processing.

- Power Generation: Biomass-based power plants utilize rice straw to generate electricity, reducing dependence on fossil fuels.

- Co-Generation: In some industries, rice straw is used for combined heat and power (CHP) production, maximizing energy efficiency.

Interesting Fact: A typical biomass power plant in India, using rice straw, generates around 10-15 MW of electricity — enough to power a medium-sized town. Such plants have a biomass consumption rate of around 60,000 – 80,000 tons of rice straw annually.

Forms in Which Rice Straw is Used in Industries

Industries utilize rice straw in several processed forms to maximize efficiency:

- Baled Rice Straw: Compressed bales are easy to transport and handle. This is the most common form used for direct combustion in industrial boilers.

- Pellets and Briquettes: Compressed and densified pellets or briquettes provide higher energy density. They are preferred in smaller-scale applications or where storage space is limited.

- Shredded Rice Straw: Some industries directly shred rice straw to feed it into furnaces, though this is less common due to handling difficulties.

Boilers Using Rice Straw

Modern biomass boilers have adapted to accommodate agricultural residues like rice straw:

- Fluidized Bed Combustion (FBC) Boilers: These are highly efficient and can handle diverse biomass fuels. Rice straw is burned in a bed of hot particles, ensuring complete combustion and reducing emissions.

- Moving Grate Boilers: Ideal for baled rice straw, these boilers have a moving grate that feeds the straw into the combustion chamber, providing steady heat for industrial processes.

- Hybrid Boilers: These systems combine the features of FBC and grate boilers, allowing flexibility in fuel use, including rice straw mixed with other biomass.

Specific Fact: According to a report by the Ministry of New and Renewable Energy (MNRE), over 40 biomass boilers using rice straw are operational across India, contributing significantly to the industrial heat and power sector.

Amount of Rice Straw Being Used by Industries for Industrial Heating

The utilization of rice straw for industrial heating has seen substantial growth, particularly in northern states like Punjab, Haryana, and Uttar Pradesh where rice cultivation is prominent.

- Punjab: Annually produces approximately 20 million tons of rice straw, of which around 1.5 – 2 million tons are currently utilized for biomass-based power and industrial heating.

- Haryana: Generates about 7 million tons of rice straw yearly, with around 500,000 tons used in industrial heating and power plants.

- Uttar Pradesh: A significant contributor, with about 16 million tons of rice straw produced, with roughly 1 million tons finding use in energy applications.

Interesting Fact: India has the potential to generate over 17,000 MW of electricity from rice straw alone, given its annual production volume.

Prominent Industries Using Rice Straw for Industrial Heating

Several industries have embraced rice straw as an eco-friendly energy source:

- Paper and Pulp Industry: These industries have significantly shifted to biomass boilers to generate process steam. For instance, paper mills in Punjab utilize baled rice straw for their energy requirements.

- Food Processing: Rice straw is used for steam generation in food processing units for drying, sterilization, and cooking.

- Textile Industry: In some regions, rice straw-fired boilers produce the steam needed for dyeing and processing fabrics.

- Distilleries and Breweries: Biomass boilers powered by rice straw provide consistent heat for distillation processes.

- Biomass Power Plants: Companies like Punjab Biomass Power Ltd. and Sukhbir Agro Energy Limited are prominent players in utilizing rice straw for power generation.

Fact: The Punjab State Power Corporation Limited (PSPCL) has signed agreements with several biomass power developers to procure electricity generated from rice straw, supporting the state’s energy grid.