Key Questions Answered in this Section

- What are cashew nut shells, and why are they considered valuable for biomass feedstock?

- How much cashew nut shell biomass is generated annually in India, and where is it primarily available?

- What are the key characteristics of cashew nut shells in loose and briquette forms?

- How is Cashew Nut Shell Liquid (CNSL) extracted and utilized in industrial applications?

- What are the primary uses of cashew nut shells in industrial heating and power generation?

- How are cashew nut shells processed into briquettes, pellets, or other forms for industrial use?

- Which industries in India use cashew nut shells as a sustainable energy source?

- What types of boilers are suitable for burning cashew nut shells, and how do they enhance combustion efficiency?

- What challenges do industries face in collecting, processing, and transporting cashew nut shells as biomass fuel?

- How does the use of cashew nut shells for energy compare to traditional fossil fuels like coal in terms of environmental and economic benefits?

- How is the price of cashew nut shell biomass in loose form determined, and what factors influence the cost in India?

- How is the price of cashew nut shell biomass in briquette form determined, and what factors influence the cost?

- Is it possible to directly use cashew nut shells in boilers?

Introduction

Cashew nut shells, the outer coverings of the cashew seed, are a valuable byproduct of cashew nut processing. These shells make up about 65% of the raw cashew weight and are a rich source of biomass due to their high lignocellulosic content. Cashew nut shells contain cellulose (20-25%), hemicellulose (8-12%), and lignin (25-30%), making them suitable for various bioenergy applications.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

A key feature of cashew nut shells is the presence of Cashew Nut Shell Liquid (CNSL), a phenolic oil that comprises about 25% of the shell’s weight. CNSL is a valuable industrial feedstock used in the production of biofuels, resins, and biochemicals. The remaining shell, after CNSL extraction, can be converted into biochar, solid fuels like pellets or briquettes, or used for direct combustion to generate heat and electricity.

Let us look into the price, availability, and proximate analysis of cashew nut shell briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

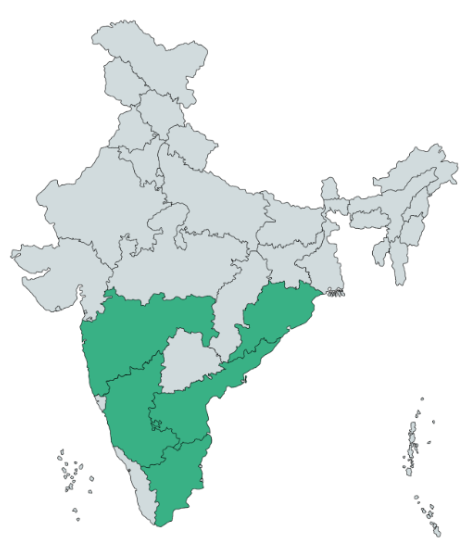

Total Cashew Nut Shell Generation in India

Annual Generation: India generates around 0.77 million tonnes per annum of cashew nut shells annually. This places it in the category of moderate availability feedstocks in India, with a concentrated supply in select coastal regions where cashew is cultivated.

Assessing the availability of cashew nut shell involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of cashew nut shell reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Parameter | Loose Form | Briquette Form |

| Gross Calorific Value (GCV) | 4,800 kcal/kg | |

| Moisture Content | 10% | 7% |

| Ash Content | 2% | 3-4% |

| Silica Content | 1-2% | 1-2% |

| Volatile Matter | 72% | 40% |

| Fixed Carbon | 20% | 30% |

| Bulk Density | 300-320 Kg/m3 | 750-850 Kg/m3 |

| Price | ₹4/Kg | ₹7.5/Kg |

Seasonality

The cashew harvest season in India varies by region due to climatic differences. Key details include:

- Kerala: February to May

- Maharashtra: March to June

- Goa: April to June

- Tamil Nadu: March to May

- Andhra Pradesh: February to April

While fresh cashews are typically available from March to May, you can find them year-round. Optimal quality tends to be during and right after the peak harvest months.

- Storage: CNS can be stored easily for up to 4-6 months, which helps mitigate the seasonal impact and allows year-round availability.

| Month | Kerala | Maharashtra | Goa | Tamil Nadu | Andhra Pradesh |

| January | ❌ | ❌ | ❌ | ❌ | ❌ |

| February | ✅ | ❌ | ❌ | ❌ | ✅ |

| March | ✅ | ✅ | ❌ | ✅ | ✅ |

| April | ✅ | ✅ | ✅ | ✅ | ✅ |

| May | ✅ | ✅ | ✅ | ✅ | ❌ |

| June | ❌ | ✅ | ✅ | ❌ | ❌ |

| July | ❌ | ❌ | ❌ | ❌ | ❌ |

| August | ❌ | ❌ | ❌ | ❌ | ❌ |

| September | ❌ | ❌ | ❌ | ❌ | ❌ |

| October | ❌ | ❌ | ❌ | ❌ | ❌ |

| November | ❌ | ❌ | ❌ | ❌ | ❌ |

| December | ❌ | ❌ | ❌ | ❌ | ❌ |

Regional Availability

Regions with abundant cashew nut shell availability can leverage this resource for use in boilers, promoting sustainable energy practices.

| State | Total production in tonnes per annum (TPA) | Total Cashew Nut Shell Generation (TPA) | Key regions |

| Maharashtra | 199,700 | 129,805 | South Konkan Region (Rajgad and Ratnagiri districts), Sindhudurg, Thane, Palghar |

| Andhra Pradesh | 127,200 | 82,680 | Srikakulam, Vizianagaram, Palasa, Anakapalle, Parvathipuram Manyam |

| Odisha | 121,300 | 78,845 | Koraput, Dhenkanal, Malkanagiri, Ganjam |

| Karnataka | 77,900 | 50,635 | Dakshina Kannada, Udupi, Belgaum, Chickballapur, Uttara Kannada, Kodagu, Kolar |

| Tamil Nadu | 77,300 | 50,245 | Ariyalur, Cuddalore, Pudukottai, Villupuram, Theni, Sivagangai, Panruti |

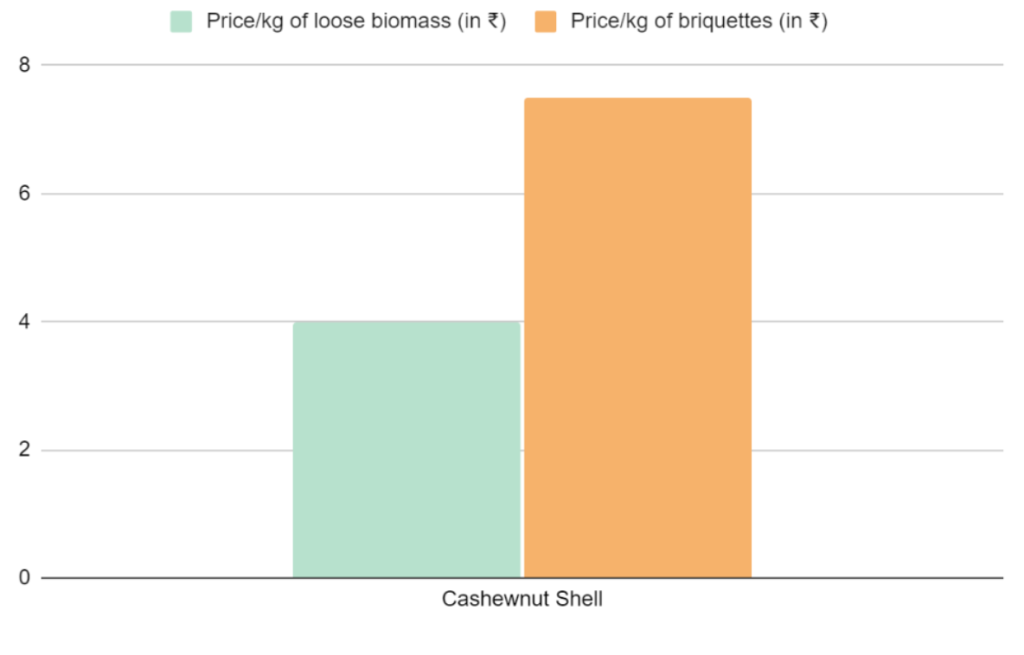

Prices

- Price of Raw Biomass: Cashew Nut Shell typically costs around ₹4 per kg in its raw form.

- Price of Briquettes: If processed into briquettes, the price increases to around ₹7.5 per kg. The relatively high price for both raw and briquetted forms is due to competition with its non-fuel uses and the fact that its supply chain is not yet fully organized.

- Fluctuations in cashew nut shell price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

Uses of Cashew Nut Shells

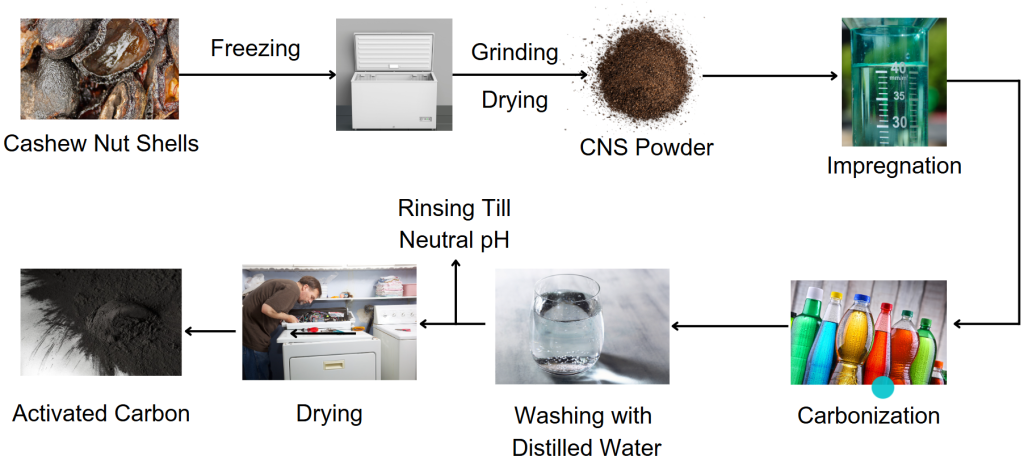

- Activated Carbon: Used to create activated carbon for water purification and heavy metal adsorption.

- Industrial Applications: CNSL derivatives are used in resins, varnishes, and friction materials like brake linings.

- Larvicidal and Antimicrobial Agent: CNSL is used in solutions to kill mosquito larvae and as an antimicrobial agent in oral health products.

- Lubrication: CNSL can be used as lubrication and starting point for chemicals.

- Antimicrobial Agents: Anacardic acid extracted from shells is used in pharmaceuticals and for antimicrobial applications.

Storage of Cashew Nut Shells

- Moisture Content: CNS should be stored with moisture levels below 10% to prevent microbial growth and self-heating.

- Storage Conditions: Store CNS in dry, ventilated warehouses to minimize moisture absorption and risk of fire. Regular temperature monitoring is necessary.

- Storage Duration: To prevent degradation, CNS should ideally be used or processed within 6 months of storage.

- Fire Hazard: CNS oil is highly flammable. Storage areas must be equipped with fire suppression systems and follow strict fire safety regulations.

- Proper storage ensures that cashew nut shell briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Cashew Nut Shell as Feedstock – Key Challenges

- Limited collection and processing infrastructure: India processes around 1.8 million tons of raw cashew nuts annually, generating significant shell waste. However, the infrastructure for collecting and processing this biomass is underdeveloped, limiting efficient utilization.

- Low awareness and adoption of technology: Despite having potential as a biofuel and chemical feedstock, many industries are unaware of technologies like pyrolysis and bio-refining to convert cashew nut shells into valuable products, including bio-oil and activated carbon.

- Inconsistent supply chain: The cashew shell supply is fragmented, primarily due to small-scale cashew farms, which leads to inconsistent and unreliable feedstock availability.

- Environmental concerns: Traditional methods of cashew shell disposal (burning or landfilling) create environmental pollution. Although cashew shells can be a renewable energy source, outdated practices are still prevalent, reducing the potential for eco-friendly applications.

- Logistics costs: Transporting cashew shells from rural processing units to industrial centers is costly, especially with high fuel prices and poor infrastructure in many cashew-growing regions. This adds to the economic burden for companies aiming to utilize the shells as feedstock.

Cashew Nut Shells for Industrial Heating and Power Generation

Uses of Cashew Nut Shell for Industrial Heating and Power Generation

Cashew nut shells are not just agricultural waste; they are a goldmine for sustainable energy. Cashew Nut Shell Liquid (CNSL), extracted from the shells, is a crucial ingredient in energy production. This liquid, combined with the fibrous husk, can be burned to generate heat and power. The applications in India are diverse:

- Industrial Boilers: CNS is widely used as a fuel source in industrial boilers to generate steam and heat for various manufacturing processes.

- Power Generation: Some power plants use CNS as a biomass fuel to generate electricity, promoting sustainable and renewable energy sources.

- Heating Applications: From textile dyeing to food processing, CNS provides consistent and cost-effective heat energy, reducing dependency on conventional fossil fuels.

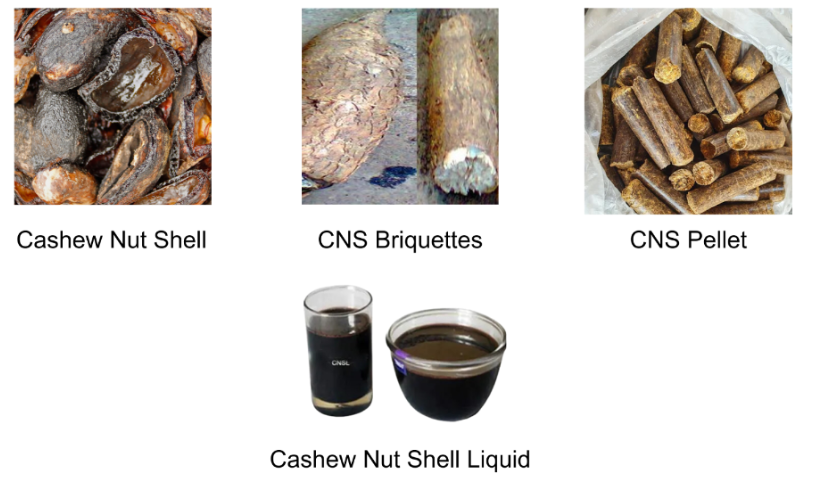

Forms in Which Cashew Nut Shell is Used in Industries

Industries utilize cashew nut shells in various forms, depending on their heating or energy needs. Here are the primary forms:

- Raw Cashew Nut Shells: These are used in biomass boilers directly after processing.

- Cashew Nut Shell Liquid (CNSL): A high-energy liquid extracted from the shell, often used as a binding agent in briquettes or directly burned for energy.

- Briquettes: Cashew nut shells are often compressed into briquettes, a more compact and manageable form of biomass with high calorific value.

- Pellets: Similar to briquettes, pellets are another refined form where cashew shells are ground and molded into small, dense pellets, suitable for controlled combustion.

Boilers Using Cashew Nut Shells

Industrial boilers are at the forefront of CNS utilization in India. Several types of boilers have been adapted or designed to run efficiently on cashew nut shell fuel:

- Fluidized Bed Combustion Boilers (FBC): These boilers are highly efficient in burning low-grade fuels like CNS. They create a fluidized bed of burning material, allowing for thorough combustion and high heat transfer.

- Stoker Boilers: Equipped with a moving grate, these boilers handle the burning of cashew nut shells well, providing consistent heat output.

- Package Boilers: Often used by smaller industries, these boilers are compact and can be fueled with CNS briquettes or pellets for localized heating needs.

Amount of Cashew Nut Shells Being Used by Industries for Industrial Heating

India’s vast cashew processing industry produces a significant quantity of cashew nut shells. Here are some interesting figures:

- Annual CNS Production: India processes about 1.8 million metric tonnes of raw cashews annually, generating approximately 450,000 tonnes of cashew nut shells.

- Energy Value: CNS has an impressive calorific value of about 4,800 to 5,000 kcal/kg, making it a potent source of industrial energy. A tonne of CNS can replace about 1.2 tonnes of coal, significantly lowering carbon emissions.

- Usage in Biomass Boilers: Industries using biomass boilers in India often blend CNS with other agro-residues. On average, 35% of the biomass input in these boilers is comprised of CNS.

Prominent Industries Using Cashew Nut Shell for Industrial Heating

India’s shift towards sustainable energy has seen several industries adopt CNS as a reliable and eco-friendly fuel source. Some key players include:

- Textile Industry: One of the largest consumers of heat energy, textile manufacturers in Tamil Nadu and Gujarat use CNS in biomass boilers to power dyeing, bleaching, and washing processes.

- Food Processing: Many food processing units, especially in Kerala and Karnataka, use CNS to generate steam and heat for cooking and drying, especially in spice and coffee processing.

- Paper & Pulp Industry: Biomass boilers fueled with CNS are common in the paper and pulp sector for heating processes like pulping and bleaching.

- Cashew Processing: Interestingly, some cashew processing facilities use the shells they produce to power their operations, achieving a closed-loop energy system.

- Small-scale Power Plants: Biomass-based power plants, particularly in Andhra Pradesh, have integrated CNS as a key fuel source, generating local electricity for rural areas.