Key Questions Answered in this Section

- What are groundnut shells, and how are they utilized as biomass feedstock in India?

- How much groundnut shell biomass is generated annually in India?

- What are the key characteristics of groundnut shells for energy production?

- In which regions are groundnut shells most abundantly available in India?

- In which seasons are groundnut shells most abundantly available in India?

- What are the current and emerging uses of groundnut shells across industries?

- How are groundnut shells stored to maintain their calorific value and usability?

- What challenges affect the use of groundnut shells as a biomass feedstock?

- How are groundnut shells used for industrial heating and power generation in India?

- What are the benefits of groundnut shell briquettes and pellets for industrial use?

- Which industries in India are leading in the adoption of groundnut shells for energy production?

- Is it possible to use groundnut shells in loose form in boilers?

Introduction

Groundnut shells, the by-product of peanut processing, serve as a valuable biomass feedstock due to their abundance and high energy content. These shells are primarily composed of cellulose, hemicellulose, and lignin, making them suitable for various energy applications, such as biofuel production, combustion, and gasification.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Groundnut shells can be processed into briquettes and pellets, providing a sustainable fuel alternative for industrial boilers. Here we are going to see the price, availability, proximate analysis, and use of briquettes and pellets in boilers and logistics.

Total Groundnut Shell Generation in India

- India generates around 3 million tonnes of groundnut shells annually from groundnut processing units.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of groundnut shell briquettes reveals their suitability for efficient combustion in boilers

| Characteristic | Raw Biomass | Briquette Form |

| Gross Calorific Value | —– | 4000 Kcal/kg |

| Moisture Content | 11% | 8% |

| Ash Content | 3% | 4% |

| Silica Content | <2% | 2% |

| Volatile Matter | 81% | 77% |

| Fixed Carbon | 16% | 20% |

| Bulk density | 255 Kg/m3 | 680 Kg/m3 |

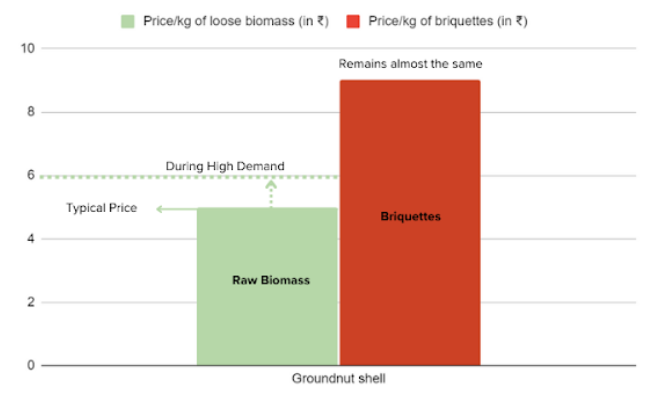

| Price | ₹4-6 per kg | ₹9 per kg* |

* – The price of groundnut shell briquettes and pellets varies based on market demand and availability

Seasonality

| Main States | Summer Season (January to May) | Kharif Season (June to September) | Rabi Season (October to March) |

| Gujarat | ✅ | ✅ | ❌ |

| Andhra Pradesh | ❌ | ✅ | ✅ |

| Tamil Nadu | ❌ | ✅ | ✅ |

| Karnataka | ✅ | ✅ | ❌ |

| Maharashtra | ✅ | ✅ | ❌ |

| Rajasthan | ✅ | ✅ | ❌ |

| Odisha | ❌ | ❌ | ✅ |

| West Bengal | ❌ | ❌ | ✅ |

| Uttar Pradesh | ✅ | ❌ | ❌ |

Note:

Kharif Season (Monsoon): June to September, Rabi-Summer Season (Post-rainy): October to March, Summer Season (Spring/Summer): January to May

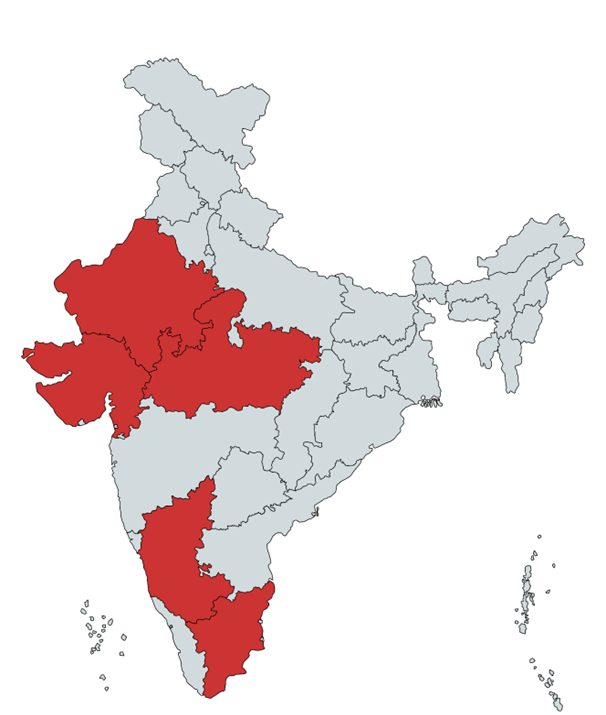

Regional Availability

The following are the top five states in India where groundnut is abundantly available, along with key regions within those states:

| State | Annual Groundnut Production (MTPA) | Annual Groundnut Shell Generation (MTPA) | Key Regions |

| Gujarat | 4.5 | 1.35 | Saurashtra, Rajkot, Amreli, Bhavnagar, Jamnagar, Morna, Khadi |

| Rajasthan | 1.7 | 0.51 | Bikaner, Churu, Hanumangarh, Jodhpur, Nagaur, Sikar, Dausa, Jaipur |

| Tamil Nadu | 0.95 | 0.28 | Panruti, North Arcot, South Arcot, Salem, Coimbatore |

| Madhya Pradesh | 0.67 | 0.2 | Khargone, Badwani, Chhindwada, Seoni, Betul, Datiya, Shivpuri, Tikamgarh, Chhatarpur |

| Karnataka | 0.55 | 0.16 | Dharwad, Belgaum, Bijapur, Raichur, Bellary, Bidar |

Prices

- Loose biomass (groundnut shells) is priced between ₹4-6 per kilogram, while briquettes made from groundnut shells are priced at around ₹9 per kilogram.

- The price tends to show some seasonal volatility, often increasing during non-harvesting periods due to lower availability.

Uses of Groundnut Shell

Current Uses

- Activated Carbon: Used to produce activated carbon for adsorbing heavy metals and organic pollutants from water.

- Animal Feed: Groundnut shells are sometimes used as a feed ingredient due to their fibre content, though this is less common

- Others: Can be used for making particle boards and also in mulching.

Emerging Uses

- Concrete Production: Incorporated as a partial replacement for fine aggregates in concrete, reducing pollution and creating light load-bearing structures.

Storage of Groundnut Shells

Proper storage of groundnut shell briquettes and pellets is crucial to maintain their quality for use in boilers. Here are some essential notes on the storage of groundnut shells:

1. Moisture Content and Its Impact on Storage

- Optimal Moisture Content: Groundnut shells should ideally have a moisture content below 10-12% for safe long-term storage. Higher moisture content leads to microbial growth, decomposition, and loss of calorific value, which can hinder their use as biomass feedstock.

- Humidity Challenges: In regions of India with high humidity, such as coastal areas or during the monsoon season, it is crucial to control the moisture content of groundnut shells through proper drying and ventilation during storage. Inadequate moisture control can result in fungal contamination.

2. Calorific Value and Energy Use

- Calorific Value: Groundnut shells have a calorific value of approximately 4,000kcal/kg, making them a useful biomass for energy production in boilers, gasifiers, and even for biofuel conversion. However, improper storage (with high moisture or contamination) can reduce this energy potential.

- Storage Duration: Groundnut shells can be stored for up to 6 months without significant degradation, provided they are kept in dry, well-ventilated areas. Beyond this period, their calorific value might decrease due to moisture absorption and biological degradation.

3. Storage Infrastructure Requirements

- Traditional Storage Methods: In rural India, groundnut shells are often stored in bulk in open or semi-covered spaces, which exposes them to weather and pest attacks. This method is inexpensive but may lead to significant losses.

- Improved Storage Methods: Warehouses or storage sheds with proper ventilation and moisture control are preferred for large-scale storage. Storing the shells in bags made of jute or polypropylene allows for better handling and protection from pests, especially in monsoon-prone areas like Gujarat, Andhra Pradesh, and Tamil Nadu.

4. Pest Control and Contamination

- Pest Infestation: Groundnut shells are prone to infestations by termites, beetles, and rodents. Fumigation and regular monitoring are essential for pest control. Use of neem or other natural repellents is also practiced in some areas to mitigate pest attacks during storage.

- Fungal Growth: Aflatoxin contamination is a concern in peanut shells as well, especially when stored in humid conditions. This can make the feedstock unsuitable for further use in both energy production and as animal feed.

Groundnut Shell as Feedstock – Key Challenges:

- Competing Uses: Groundnut shells are used for producing particle boards, briquettes, and as livestock bedding, limiting their availability as feedstock for bioenergy.

- Lack of Standardization: The absence of uniform standards for groundnut shell quality and moisture content hampers their widespread use in industries.

Groundnut Shells for Industrial Heating and Power Generation in India

Groundnut shells, a byproduct of the peanut processing industry, have emerged as a promising biomass fuel in India, particularly for industrial heating and power generation. As India’s industrial sector seeks sustainable and cost-effective energy sources, groundnut shells are stepping into the spotlight as an abundant, renewable, and economically viable alternative to conventional fuels.

Let’s explore the uses, benefits, challenges, and trends associated with groundnut shells in India’s industrial energy landscape.

1. Uses of Groundnut Shells for Industrial Heating and Power Generation

Groundnut shells are primarily used in two areas:

- Industrial Heating: Factories and plants are increasingly adopting groundnut shells as a fuel source for generating process heat. This is particularly common in sectors such as textiles, food processing, pharmaceuticals, and chemicals, where the need for steam and heat is high.

- Power Generation: In biomass power plants, groundnut shells are being utilized to generate electricity. These shells are burnt to produce steam, which drives turbines for electricity generation. While power generation from groundnut shells is still a developing field in India, its potential to contribute to renewable energy is significant.

Key Benefits:

- Cost-Effective: Groundnut shells are cheaper compared to coal and other fossil fuels.

- Eco-Friendly: They are considered carbon-neutral, releasing only the carbon dioxide absorbed during the plant’s lifecycle.

- Readily Available: India is one of the world’s largest producers of groundnuts, making the shells easily accessible for industrial use.

2. Form in Which Groundnut Shells are Used in Industries

Groundnut shells can be processed into different forms to enhance their usability as a biomass fuel:

- Raw Groundnut Shells: These are directly collected from the groundnut processing units and used in small-scale furnaces and kilns.

- Groundnut Shell Pellets: The shells are compacted into pellets for uniformity and ease of handling. Pellets are more efficient as they have a higher calorific value, leading to better combustion.

- Groundnut Shell Briquettes: These are larger, compressed blocks that can replace coal in industrial boilers and large-scale heating systems. Briquettes burn longer and more steadily, making them ideal for continuous heating.

Industries tend to prefer pellets and briquettes due to their higher energy density, storage efficiency, and consistent quality.

3. Boilers Using Groundnut Shells

Several types of boilers are designed to utilize groundnut shells as fuel:

- Biomass Boilers: These boilers are specifically engineered to handle agricultural waste like groundnut shells. They provide a controlled combustion process that maximizes heat output.

- Fluidized Bed Combustion (FBC) Boilers: FBC boilers are popular in India for their ability to burn low-quality biomass, including groundnut shells. They are known for their high efficiency and ability to handle various fuel forms.

- Stoker-Fired Boilers: Common in industries that use pellets or briquettes, these boilers have automated feeding systems and can maintain consistent heat output.

With a thermal efficiency range of 70-80%, these biomass boilers are replacing traditional coal-fired boilers, contributing to cleaner industrial operations.

4. Amount of Groundnut Shells Being Used by Industries for Industrial Heating

India’s industrial use of groundnut shells for energy is growing, especially in biomass-rich states like Gujarat, Andhra Pradesh, and Tamil Nadu. Here are some key data points:

- Annual Groundnut Shell Production: India produces around 3 million metric tonnes of groundnut shells annually, primarily concentrated in states with high groundnut cultivation.

- Consumption for Biomass Heating: It’s estimated that approximately 10-15% of groundnut shells are currently utilized for industrial heating, equating to around 200,000 to 300,000 tonnes per year.

- Cost of Groundnut Shells: The price of groundnut shells varies between ₹4,000 to ₹6,000 per tonne, making them an economical choice compared to coal, which ranges from ₹6,000 to ₹8,000 per tonne.

This growing consumption indicates a shift towards renewable biomass for industrial heating, driven by rising coal costs and environmental concerns.

5. Prominent Industries Using Biomass for Industrial Heating in India

While the use of groundnut shells is expanding, several industries have already embraced biomass, including sawdust, for their heating needs. Prominent sectors include:

- Textile Industry: Gujarat and Tamil Nadu are home to numerous textile mills using biomass boilers for dyeing, finishing, and steam generation.

- Food Processing Units: Andhra Pradesh’s food processing sector has adopted biomass boilers for drying and processing operations, utilizing both groundnut shells and sawdust.

- Pharmaceuticals: Maharashtra and Telangana’s pharma industries use biomass boilers for controlled heating, a vital aspect of drug manufacturing.

- Brick Manufacturing: Biomass fuels like groundnut shells and sawdust are replacing coal in brick kilns, particularly in Punjab and Haryana, where local biomass is readily available.