Key Questions Answered in this Section

- What are castor seed shells, and how are they generated as a byproduct of castor seed processing?

- How much castor seed shell biomass is produced annually in India, and which regions contribute the most?

- What are the characteristics of castor seed shells in loose and briquette forms?

- Why are castor seed shells considered an efficient and renewable energy source for industrial heating and power generation?

- How are castor seed shells used for applications like soil amendments, water purification, and biochar production?

- What are the challenges in storing, transporting, and using castor seed shells as biomass fuel?

- How are castor seed shells processed into forms like briquettes, pellets, or crushed powder for industrial use?

- Which types of boilers are most suitable for burning castor seed shells in industrial settings?

- How do industries like textiles, pharmaceuticals, and food processing use castor seed shells for heating needs?

- What is the environmental and economic impact of using castor seed shells as an alternative to fossil fuels?

- Is it possible to directly use castor seed shells in boilers?

Introduction

Castor seed shells, the outer husk remaining after the extraction of castor seeds, are a valuable biomass feedstock. These shells are rich in lignocellulosic material, making them suitable for energy production through combustion, pyrolysis, or gasification.

Due to their high carbon content and low ash residue, castor seed shells are considered an efficient and renewable energy source. Additionally, they can be used for biochar production, soil amendments, and as a substrate for biofuel generation, contributing to sustainable waste management and energy solutions. Let us look into the price, availability, and proximate analysis of castor seed shell briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Total Castor Seed Shell Generation in India

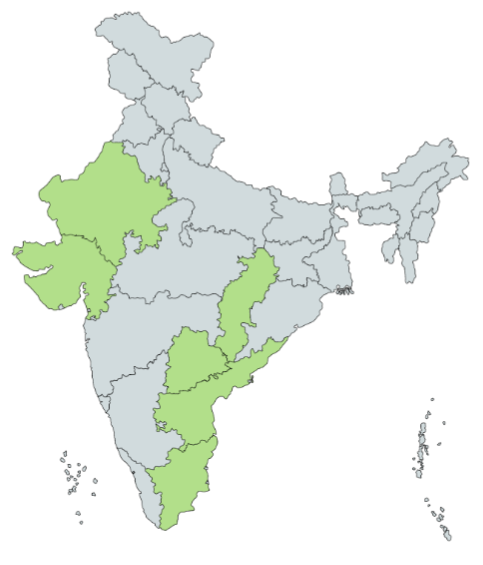

About 0.45 million tonnes of castor seed shell biomass are generated annually in India. The primary region of production is Gujarat. Assessing the availability of castor seed shell involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of castor seed shell reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Parameter | Loose Form | Briquette Form |

| Gross Calorific Value (GCV) | 3800 Kcal/kg | |

| Moisture Content | 10% | 7% |

| Ash Content | 8% | 8.5% |

| Silica Content | <2% | <2% |

| Volatile Matter | 72% | 70% |

| Fixed Carbon | 16% | 16% |

| Bulk Density | 400 Kg/m3 | 650-700 Kg/m3 |

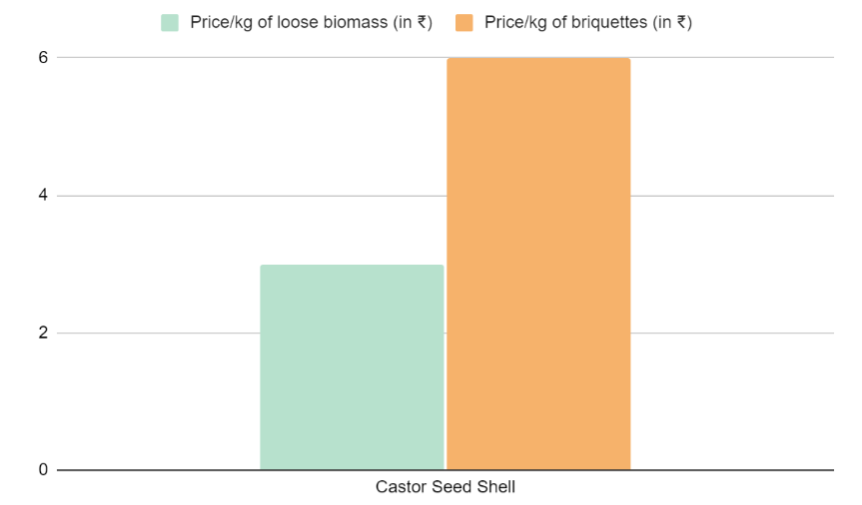

| Price | ₹3/kg | ₹6/kg |

Seasonality

- Castor is generally sown in July-August and harvested from December to March across India.

- The peak arrival season in markets, particularly in Gujarat, is March-April.

- For Andhra Pradesh and other Southern States, the optimal sowing time is from the second fortnight of June.

- In Gujarat and Rajasthan, the best sowing time is the first fortnight of July.

- For a rabi season crop, sowing from September 15 to October 15 is ideal, while for a summer crop, January is the appropriate time.

| Region/Season | Sowing Period | Harvest Period |

| India (General) | July-August | December to March |

| Gujarat (Peak Market Arrival) | March-April | March-April (Market Arrival) |

| Southern States | Second fortnight of June | Varies based on sowing |

| Gujarat & Rajasthan (Best Sowing) | First fortnight of July | Varies based on sowing |

| Rabi Season (Ideal Sowing) | September 15 to October 15 | December to March (Rabi) |

| Summer Crop (Ideal Sowing) | January | Varies based on sowing |

Regional Availability

Regions with abundant castor seed shell availability can leverage this resource for use in boilers, promoting sustainable energy practices.

| State | Total Castor Seed Production (MTPA) | Total Castor Seed Shell Generation (MTPA) | Key regions |

| Gujarat | 1.03 | 0.3 | Sabarkantha, Banaskantha, Mehsana, Patan |

| Rajasthan | 0.2 | 0.06 | Jalore, Sirohi, Barmer, Jodhpur |

| Andhra Pradesh | 0.09 | 0.02 | Kurnool, Anantapuram, Prakasam |

| Telangana | 0.004 | 0.001 | Mahboobnagar, Nalgonda |

| Chhattisgarh | 0.002 | 0.0006 | Raipur, Narayanpur |

| Tamilnadu | 0.001 | 0.0003 | Salem, Namakkal, Erode, Dharmapuri and Perambalur. |

Prices

- Price of Raw Biomass: Castor seed shell is priced at ₹3/kg for loose biomass.

- Price of Briquettes: When processed into briquettes, the price is approximately ₹6/kg, making it a moderately priced biomass feedstock for energy applications.

- Fluctuations in castor seed shell price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

Uses of Castor Seed Shell

Current Uses

- Soil Amendment: Ground castor shells are utilized as a soil amendment due to their rich nutrient content.

- Has very few non-fuel alternative uses as it is toxic.

Emerging Uses

- Water Purification: Used as an adsorbent to remove heavy metals like lead from contaminated water.

- Adsorbent for Dye Removal: Employed to remove dyes like Methylene Blue from water, leveraging its high sorption capacity.

Storage of Castor Seed Shells

- Moisture content: Ideal moisture content for storing castor seed shell feedstock is between 8-10% to avoid mold growth and microbial degradation.

- Storage facilities: For bulk storage, silos or warehouses are commonly used. Proper ventilation is essential to prevent moisture accumulation. Hermetic storage is also an option to avoid pest infestation.

- Temperature control: Recommended storage temperature is below 25°C to reduce the risk of spoilage and maintain feedstock quality. Hot, humid conditions in some regions may necessitate artificial cooling.

- Pest control: Castor seed shells are susceptible to pest attacks, particularly from rodents and insects. Chemical fumigation (e.g., phosphine) or natural methods (e.g., neem leaves) are often used for pest management.

- Shelf life: Under optimal storage conditions, castor seed shell feedstock can be stored for up to 6 months without significant deterioration.

- Proper storage ensures that castor seed shell briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Castor Seed Shell as Feedstock – Key Challenges

- Castor seed shells generally have low bulk density, which can lead to inefficient transportation, storage, and handling.

- The chemical composition of castor seed shells (high potassium and chlorine levels) can cause agglomeration, slagging, and corrosion inside the boiler.

Castor Seed Shells for Industrial Heating and Power Generation

Uses of Castor Seed Shell for Industrial Heating and Power Generation:

- Industrial Heating: Castor seed shells are widely used in industries for heating boilers and furnaces. Due to their high energy content, they provide consistent and efficient heat for various industrial processes like drying, chemical synthesis, and steam generation.

- Power Generation: Some industries are harnessing castor seed shells for small-scale power generation. The combustion of castor shells in biomass boilers produces steam, which can be used to generate electricity. This is particularly valuable in areas with limited access to conventional electricity, offering a renewable energy solution.

- Sustainable Energy Source: Using castor seed shells helps industries reduce their carbon footprint. Since they are a byproduct of the already flourishing castor oil industry, their use as biomass fuel doesn’t compete with food resources and aligns with India’s goals for sustainable industrial growth.

Form in Which Castor Seed Shell is Used in Industries

Industries often use castor seed shells in the following forms:

- Raw Form: In some cases, the shells are used directly after separation from the seed, particularly in small-scale industries with direct combustion boilers.

- Pellets or Briquettes: Many industries prefer castor seed shells in pellet or briquette form, as it is easier to handle, store, and transport. This form also offers higher combustion efficiency due to uniform size and density.

- Crushed Powder: For more controlled combustion and specific heating requirements, the shells are sometimes crushed into finer particles, ensuring better feed control in boilers.

Boilers Using Castor Seed Shell

Several types of boilers are suitable for burning castor seed shells:

- Fluidized Bed Boilers: These are highly efficient for burning biomass like castor seed shells. They ensure even heat distribution, complete combustion, and higher efficiency, making them popular in many Indian industries.

- Grate-Fired Boilers: Common in industries using biomass, these boilers are adaptable for different fuel types, including raw castor seed shells, pellets, and briquettes. They are relatively simple to operate and maintain, making them a cost-effective option for small to medium-scale industries.

- Multi-Fuel Boilers: Designed to switch between different biomass fuels, these boilers provide flexibility to industries that might need to mix castor seed shells with other biomass residues like rice husks or sawdust.

Amount of Castor Seed Shell Being Used by Industries for Industrial Heating

India produces around 1.5 million tonnes of castor seeds annually, with Gujarat accounting for nearly 70% of the production. Given that approximately 30% of the weight of the seed is the shell, this translates to a significant amount of biomass.

While comprehensive national data is limited, it is estimated that 450,000 tonnes of castor seed shells are available annually for use as biomass fuel. In certain regions of Gujarat and Rajasthan, where castor cultivation is concentrated, biomass boilers using castor shells account for about 10-15% of the total industrial heating systems.

Prominent Industries Using Castor Seed Shell for Industrial Heating

Several Indian industries are increasingly adopting castor seed shells for their industrial heating needs:

- Textile Industry: Known for its high energy consumption, many textile factories in Gujarat and Maharashtra have switched to biomass boilers, including those fueled by castor seed shells. This transition is driven by a push for sustainable practices and cost-efficiency.

- Pharmaceutical and Chemical Industries: Castor oil processing plants themselves use the seed shells in boilers, creating a circular economy model. Some pharmaceutical and chemical factories have integrated castor shell boilers to reduce their dependency on coal.

- Food Processing Units: Industries dealing with large-scale food drying and processing have found castor shells to be a reliable source of heat. The agricultural hubs in Andhra Pradesh and Karnataka have seen a rise in biomass-based heating solutions.

- Paper and Pulp Industry: This sector has been a pioneer in biomass utilization. Castor seed shells are favored for their low ash content, reducing maintenance requirements in boilers and enhancing operational efficiency.

- Agro-Processing and Castor Oil Mills: Castor oil mills often utilize the shells as a direct energy source for their own heating needs, reducing waste disposal costs and providing a sustainable fuel source for internal operations.