Key Questions Answered in this Section

- What is rice husk, and how is it used as a renewable energy source?

- How much rice husk is produced annually in India, and which states lead in production?

- What are the main industrial applications of rice husk in biomass energy production?

- How does rice husk contribute to power generation and cogeneration systems?

- What are the advantages of using rice husk briquettes or pellets compared to loose husk?

- Why is rice husk considered an eco-friendly alternative to conventional fuels?

- What challenges are associated with the collection, storage, and transportation of rice husk?

- How do fluidized bed combustion boilers optimize rice husk utilization for energy?

- How does the high silica content in rice husk impact its use in industrial applications?

- What role does rice husk play in reducing air pollution from open-field burning?

- How is the price of rice husk in loose form determined, and what factors influence its cost in India?

- How is the price of rice husk in briquette form determined, and what factors influence its cost?

- Is it possible to directly use rice husk in boilers?

Introduction

Beneath the hard shell of every rice grain lies a surprising secret—rice husk, the protective outer layer, is a potent source of renewable energy. This often discarded byproduct, generated in millions of tons annually, is a lightweight, silica-rich material with unique properties that make it perfect for bioenergy and industrial applications.

Let us look into the price, availability, and proximate analysis of rice husk briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Total Rice Husk Generation in India

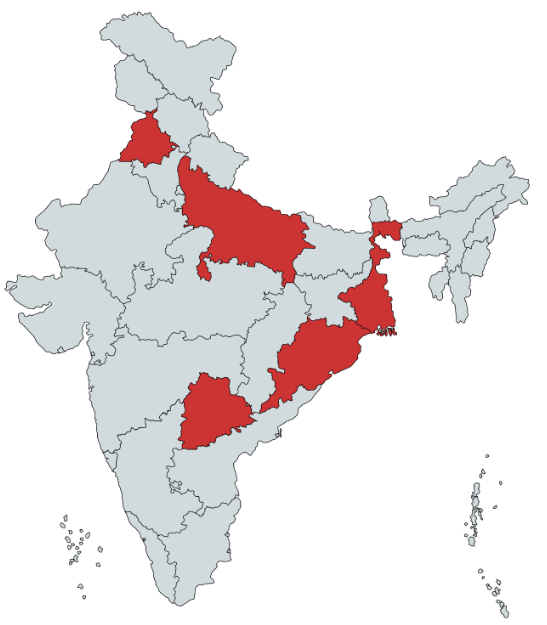

India is one of the world’s largest producers of rice, and rice husk is a significant byproduct of rice milling. Annually, India produces around 23 million tonnes of rice husk, derived from approximately 130 million tonnes of paddy. The production is concentrated in major rice-producing states such as West Bengal, Uttar Pradesh, Punjab, and Bihar. Assessing the availability of rice husk involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of rice husk reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Parameter | Loose Form | Briquette Form |

| Gross Calorific Value (GCV) | 3200 | |

| Moisture Content | 10% | 6-8% |

| Ash Content | 19% | 19% |

| Silica Content | 15-20% | — |

| Volatile Matter | 73.5% | 14% |

| Fixed Carbon | 11.5% | 74.5% |

| Bulk Density | 150-200 Kg/m3 | 650-700 Kg/m3 |

| Price | ₹3-4/kg | ₹6-6.5/kg |

Seasonality

Rice cultivation in India takes place under a wide range of altitudes and climatic conditions, leading to different rice growing seasons across the country. Factors like temperature, rainfall, soil type, and water availability significantly influence the cultivation calendar in various regions. In the eastern and southern parts of India, the temperatures are suitable for rice farming throughout the year, allowing farmers to grow two or even three crops annually. In contrast, in northern and western regions, where winters are cooler and rainfall is substantial, rice is typically grown once a year, from May to November.

Rice cultivation in India can be categorized into three main seasons—autumn, winter, and summer—based on the harvest period. Here’s a breakdown of these seasons:

Autumn Season (Pre-Kharif Rice)

Autumn rice, often referred to as pre-Kharif rice, is sown between May and August, with the harvest occurring in September and October. The specific timing of planting varies by state, depending on local weather and rainfall patterns. The crop goes by different names in different regions: Aus in West Bengal, Ahu in Assam, Beali in Odisha, Bhadai in Bihar, Virippu in Kerala, and Kuruvai/Kar/Sornavari in Tamil Nadu. This season accounts for about 7% of India’s total rice production, with most varieties being short-duration crops that mature in 90 to 110 days.

Winter Season (Kharif Rice)

The primary rice-growing season in India is the Kharif, also known as winter rice due to its harvest period. Sowing generally takes place in June and July, with harvesting from November to December. It goes by various local names, including Aman in West Bengal, Sali in Assam, Sarrad in Odisha, Agahani in Bihar and Uttar Pradesh, Sarava in Andhra Pradesh, Mundakan in Kerala, and Samba/Thaladi in Tamil Nadu. This season is responsible for around 84% of the country’s rice output, with farmers favoring medium to long-duration varieties.

Summer Season (Rabi Rice)

The summer rice crop, known as Rabi rice, is planted between November and February and harvested from March to June. Regional names include Boro in Assam and West Bengal, Dalua in Odisha, Dalwa in Andhra Pradesh, Punja in Kerala, Navarai in Tamil Nadu, and Garma in Bihar. This season covers about 9% of the rice-growing area, with early-maturing varieties being the norm.

Different states have specific planting and harvesting windows for these seasons, influenced by local climate conditions and rainfall.

| SL | Region/State | Autumn Sowing | Autumn Harvesting | Winter Sowing | Winter Harvesting | Summer Sowing | Summer Harvesting |

| 1 | Northern Region | ||||||

| Haryana | – | – | – | – | – | – | |

| Punjab | May-Aug | Sep-Nov | – | – | – | – | |

| West U.P. | – | – | – | – | – | – | |

| Himachal Pradesh | June-July | Sep-Nov | – | – | – | – | |

| Jammu & Kashmir | – | – | Apr-July | Sep-Dec | – | – | |

| 2 | Western Region | ||||||

| Gujarat | – | – | Jun-Aug | Oct-Dec | – | – | |

| Maharashtra | – | – | Jun-July | Oct-Dec | – | – | |

| Rajasthan | – | – | July-Aug | Oct-Dec | – | – | |

| 3 | North-East Region | ||||||

| Assam | Mid Feb-Apr | June-July | June-Aug | Nov-Dec | Dec-Feb | May-June | |

| 4 | Eastern Region | ||||||

| Bihar | May-July | Sep-Oct | July-Sep | Nov-Dec | Jan-Feb | May-June | |

| East M.P. | June-Aug | Mid Sep – Mid Dec | – | – | – | – | |

| Orissa | May-June | Sep-Oct | June-Aug | Dec-Jan | Dec-Jan | May-June | |

| East U.P. | May-July | Sep-Nov | July-Aug | Nov-Dec | Jan-Feb | Apr-June | |

| West Bengal | Mar-June (Broadcasting)May-June (Transplanting) | July-Nov | Apr-June (Broadcasting)July-Aug (Transplanting) | Nov-Dec | Oct-Feb | Apr-May | |

| 5 | Southern Region | ||||||

| Andhra Pradesh | Mar-April | July-Aug | May-June | Nov-Dec | Dec-Jan | April-May | |

| Karnataka | May-Aug | Sep-Dec | June-Oct | Nov-March | Dec-Feb | April-July | |

| Kerala | April-June | Aug-Oct | Sep-Oct | Jan-Feb | Dec-Jan | March-Apr | |

| Tamil Nadu | Early Samba | Late Samba | |||||

| Sonavari | April-May | July-Aug | June-July | Nov-Dec | Oct-Nov | March-Apr | |

| Samba | Navarai | ||||||

| Kar | May-June | Aug-Sep | July-Aug | Dec-Jan | Dec-Jan | April-May | |

| Thaladi/Pishanam | |||||||

| Kuruvai | June-July | Sep-Oct | Sep-Oct | Dec-Jan | – | – | |

Regional Availability

Regions with abundant rice husk availability can leverage this resource for use in boilers, promoting sustainable energy practices. The following are the top five states in India where rice is abundantly available, along with key regions within those states:

| State | Annual Rice Production (MTPA) | Annual Rice Straw Generation (MTPA) | Key Regions of State |

| West Bengal | 16 | 23 | Midnapore, Bardhaman, Dinajpur, South 24 Parganas, Birbhum, Bankura, Murshidabad, Burdwan, Hooghly, Nadia |

| Uttar Pradesh | 15 | 16 | Bijnor, Kushinagar, Pilibhit, Chandauli, Baghpat, Varanasi and Ambedkarnagar |

| Punjab | 13 | 20 | Tehgarh, Sangrur, Ludhiana, Moga, Ferozepur, Bhatinda, Jalandhar, Kapurthala, Nawanshahar, Faridkot, Patiala, Mukatsar, Mansa, Ropar, Amritsar, Hoshiarpur, Gurudaspur |

| Telangana | 12 | 17 | Nalgonda, Suryapet, Nizamabad, Siddipet, Karimnagar, Kamareddy, Yadadri, Khammam, Peddapalli, Rajanna Sircilla, Jangaon |

| Odisha | 9 | 12.5 | Baragarh, Mayurbhanj, Balasore, Bolangir, Ganjam, Kalahandi, Puri, Keonjhar, Bhadrak, Sundergarh |

Prices

- Loose Biomass: The price of loose rice straw typically ranges from ₹3-4 per kg

- Briquettes: If processed into briquettes, the price can go up to around ₹6-6.5 per kg, making it one of the more expensive biomass options.

- Fluctuations in rice husk price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

Uses of Rice Husk

Rice husk has several alternative uses apart from being a biomass feedstock for energy:

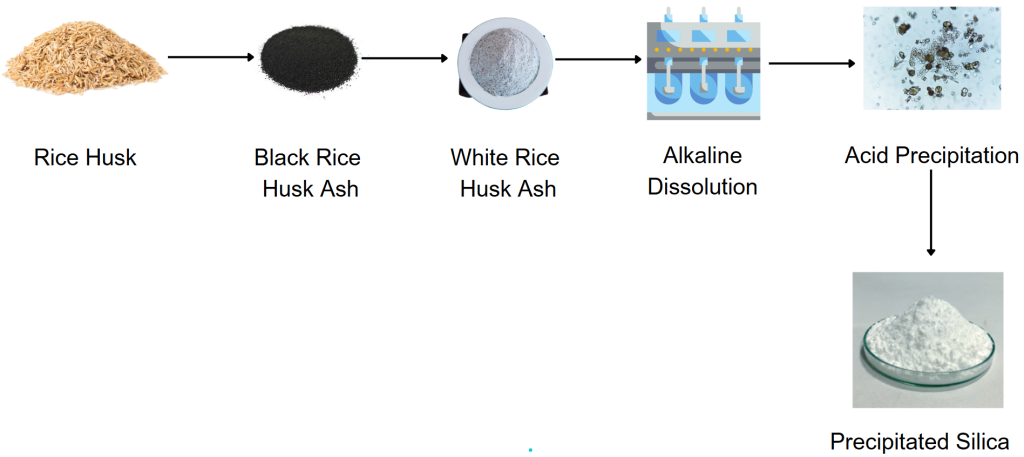

- Silica extraction: Rice husk ash, produced from combustion, is rich in silica, which can be used in industries like rubber and cement.

- Animal bedding and feed additive: Due to its absorbent properties.

- Composting and soil amendment: When used in compost, rice husk improves soil structure.

- Construction material: It is sometimes used in the production of lightweight bricks or as an insulating material.

- Biochar production: As a carbon sequestration technique.

- Activated carbon production: Used in filtration systems.

Storage of Rice Husk

- Storage Space: One ton of rice husk occupies approximately 2.5-3 cubic meters of space due to its low bulk density (90-150 kg/m³).

- Fire Hazard: Rice husk is highly flammable. Outdoor storage is common, with safety measures to reduce fire risks, such as 3-5 meters distance between stockpiles and use of fire breaks.

- Compressed Storage: Briquetting or pelletizing can reduce storage volume by up to 80%, with densities increasing to 600-800 kg/m³.

- Proper storage ensures that rice husk briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Rice Husk as Feedstock – Key Challenges

- Supply Chain Issues: India produces over 32 million tons of rice husk annually, but collection is inefficient, especially in smaller farms. Up to 30% of rice husk is wasted due to poor logistics.

- Inconsistent Quality: Rice husk has varying moisture content (8-12%) and ash levels (15-20%), affecting its suitability as biomass feedstock, particularly for energy generation.

- High Transport Costs: Being bulky and lightweight (density of around 100 kg/m³), transportation costs are high, often constituting up to 40% of total expenses.

- Low Market Price: Rice husk’s low price (₹2-4 per kg) makes it less attractive for large-scale industrial use compared to other biomass alternatives like bagasse.

Rice Husk for Industrial Heating and Power Generation

Uses of Rice Husk for Industrial Heating and Power Generation

- Biomass Boilers: A primary use of rice husk in India is as fuel for biomass boilers. Industries, particularly in agro-processing, paper, textiles, and food processing, use rice husk to produce steam for heating processes.

- Power Generation: Biomass power plants utilizing rice husk generate electricity, especially in rural regions. These plants convert husk into producer gas through gasification, then use it to run turbines, offering a reliable and renewable power source.

- Cogeneration Systems: In large rice mills, husk is used for cogeneration, producing both steam for milling operations and electricity for local grids, optimizing energy use.

Form in Which Rice Husk is Used in Industries

Rice husk can be utilized in several forms based on the industry’s needs:

- Raw Rice Husk: Directly used in biomass boilers, primarily for industries where cost efficiency is critical. Raw husk is inexpensive and readily available near rice mills.

- Rice Husk Pellets: Compressed rice husk in pellet form, which offers a denser and more efficient fuel. Pellets are used for power generation in large-scale boilers due to their consistent combustion quality and easier handling.

- Rice Husk Briquettes: Briquettes are another compact form, preferred for industrial applications requiring higher thermal efficiency.

- Rice Husk Ash (RHA): After combustion, RHA is often used in cement, refractory material, and even in the production of advanced materials like silica. Some industries reuse the ash as an insulation material or additive.

The figure above displays bagasse pellets observed at the India Bioenergy & Tech Expo held in September 2024.

Boilers Using Rice Husk

The Indian industrial sector relies heavily on rice husk for boiler-based applications. Some prominent boilers designed for rice husk usage include:

- Fluidized Bed Combustion (FBC) Boilers: Widely adopted for their ability to burn a wide range of biomass, including rice husk. These boilers are popular due to their high efficiency, low emissions, and flexibility in fuel handling.

- Chain Grate Boilers: These are used extensively in agro-industries. They allow continuous fuel feeding and effective ash management, making them suitable for rice husk combustion.

- Stoker Boilers: Common in medium to large industries, stoker boilers use mechanical feeders and operate at moderate pressures. They are known for their durability and consistent heat generation using rice husk as fuel.

Amount of Rice Husk Being Used by Industries for Industrial Heating

In India, more than 15% of the rice husk produced annually is used for industrial heating and energy production. This equates to around 3.75 million tons per year. Some key statistics:

- Power Generation: India’s biomass power plants, many of which use rice husk, have an installed capacity of around 10,000 MW.

- Rice Husk Utilization Efficiency: Around 60% of rice mills in India use rice husk as a direct source of energy for their operations.

- Boiler Fuel: Nearly 400,000 tons of rice husk are used annually by various industries as boiler fuel for generating steam.

Prominent Industries Using Rice Husk for Industrial Heating

Several industries in India utilize rice husk for heating and power, leveraging its low cost and eco-friendly attributes:

- Agro-Processing Industries:

- The rice milling sector is the largest user of rice husk for direct combustion in boilers, generating steam for drying, parboiling, and power generation.

- Large mills often employ cogeneration systems, optimizing their operational costs by utilizing waste husk.

- Textile and Garment Factories:

- Use rice husk boilers for steam-based dyeing, finishing, and washing processes.

- The shift from fossil fuels to rice husk has been prominent, especially in South India, where 40% of small and medium textile units have transitioned to biomass.

- Paper and Pulp Industries:

- Rice husk boilers generate the required steam for the pulping and drying stages. Some leading paper companies use husk to lower operational costs and reduce carbon footprints.

- Industry reports suggest that 20% of the biomass used in paper production in Northern India is rice husk.

- Food and Beverage Sector:

- Breweries and dairy processing units employ rice husk boilers for steam production, enhancing the sustainability of their operations. A key example is the dairy cooperative Amul, which uses rice husk for steam generation in its Gujarat processing facilities.