Key Questions Answered in this Section

- What is sugarcane trash, and why is it considered a valuable biomass feedstock?

- How much sugarcane trash is generated annually in India, and what is its energy potential?

- What are the key characteristics of sugarcane trash as a bioenergy feedstock?

- What are the benefits of using sugarcane trash for industrial heating and power generation?

- What challenges are associated with using sugarcane trash as biomass?

- When is sugarcane planted and harvested across different states in India?

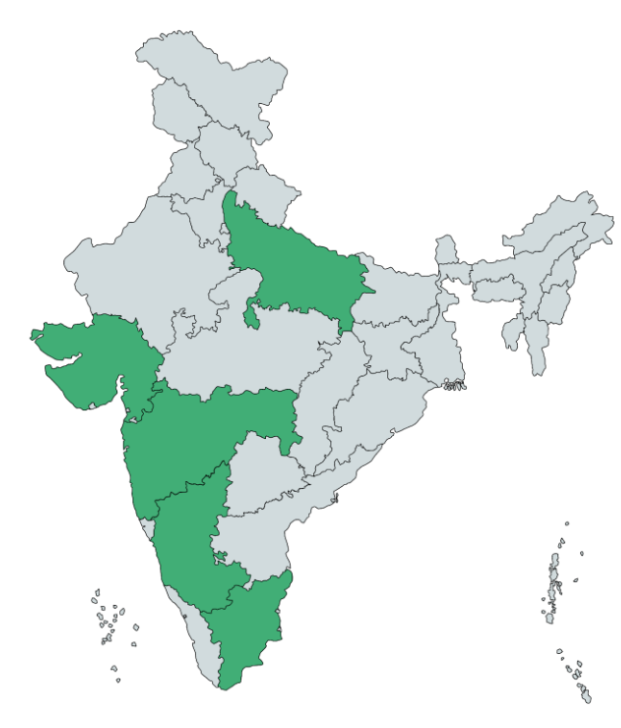

- Which regions in India produce the most sugarcane trash, and how is it used?

- How is sugarcane trash processed for industrial applications such as briquettes or pellets?

- What types of boilers are suitable for using sugarcane trash as a fuel source?

- Which industries in India are using sugarcane trash for heating and power generation, and what are the benefits?

- Is it possible to use cane trash in loose form in boilers?

Introduction

India, being the second-largest producer of sugarcane globally, generates a substantial amount of sugarcane residue, commonly known as sugarcane trash. Sugarcane trash, composed of the leaves and tops left behind after harvesting, represents a valuable yet often underutilized biomass resource. Rich in cellulose and hemicellulose, it serves as an excellent feedstock for bioenergy production, including bioethanol, biogas, and direct combustion for power generation. Despite having an energy potential comparable to bagasse, sugarcane trash is frequently wasted through open burning in fields, leading to energy loss and environmental concerns.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Remarkably, sugarcane trash holds about one-third of the total energy available in the crop. By harnessing this energy, sugar factories and sugar-producing regions can achieve sustainable development. Let us look into the price, availability, and proximate analysis of cane trash briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution

Total Sugarcane Trash Generation in India

Cane trash contributes significantly to the agricultural residues produced in India. The annual generation of cane trash is approximately 65 million tonnes.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of cane trash briquettes and pellets reveals their suitability for combustion in boilers.

| Characteristic | Raw Biomass | Briquette Form |

| Gross Calorific Value | 3800 Kcal/kg | |

| Moisture Content | 60% | 12-15% |

| Ash Content | 4% | 10-12% |

| Silica Content | 2-5% | 5-7% |

| Volatile Matter | 80% | 60% |

| Fixed Carbon | 16% | 20% |

| Bulk Density | 190-220 Kg/m3 | 8675 Kg/m3 |

| Price | ₹3-3.5 per kg | ₹5.5 per kg |

Seasonality

- Tamil Nadu: Main season (December-May) with early (Dec-Jan), mid (Feb-Mar), and late (Apr-May) crops. A special season (June-July) is also practiced, especially in certain districts.

- Karnataka: Planting occurs in Dec-Feb (Eksali, 12-month crop), Oct-Nov (Preseasonal, 15-16 month crop), and July-Aug (Adsali, 18-month crop).

- Kerala: Normal planting occurs from October to December. Planting should not be delayed beyond February in plains and post-heavy rains in hilly regions.

| Season | Tamil Nadu | Karnataka | Kerala |

| December to January | ✅ (Early crop) | ✅ (Eksali, 12-month crop) | ✅ (Normal planting season) |

| February to March | ✅ (Mid crop) | ✅(Eksali, 12-month crop) | ✅ (Should not delay beyond February) |

| April to May | ✅ (Late crop) | ✅(Eksali, 12-month crop) | ❌ |

| June to July | ✅(Special season) | ❌ | ❌ |

| July to August | ❌ | ✅(Adsali, 18-month crop) | ❌ |

| October to November | ✅ | ✅(Preseasonal, 15-16 month crop) | ✅(Normal planting season) |

| October to December | ✅ | ✅(Preseasonal, 15-16 month crop) | ✅ (Post-heavy rains in hilly regions) |

Prices

- The current price of cane trash as raw biomass is around ₹3 to ₹3.5 per kg. In briquette form, its price rises to approximately ₹5.5 per kg, making it one of the lower-cost biomass options compared to others like wheat straw or sawdust.

- Fluctuations in sugarcane price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

Regional Availability

Regions with abundant sugarcane availability can leverage this resource for use in boilers, promoting sustainable energy practices. The following are the top five states in India where sugarcane trash is abundantly available, along with key regions within those states:

| State | Annual Sugarcane Production (MTPA) | Annual Cane Trash Generation (MTPA) | Key Regions of State |

| Uttar Pradesh | 177 | 26.5 | Meerut, Bareilly, Saharanpur, Bulandshahr |

| Maharashtra | 110 | 16.5 | Pune, Satara, Solapur, Ahmednagar, Aurangabad |

| Karnataka | 61 | 9.15 | Shimoga, Mysuru, Belgaum, Chitradurga |

| Gujarat | 17 | 2.5 | Valsad, Navsari, Surat, Bharuch |

| Tamil Nadu | 15 | 2.25 | Coimbatore, Erode, Tiruppur, Trichy, Madurai, Theni, Tirunelveli |

Uses of Cane Trash

Current Uses

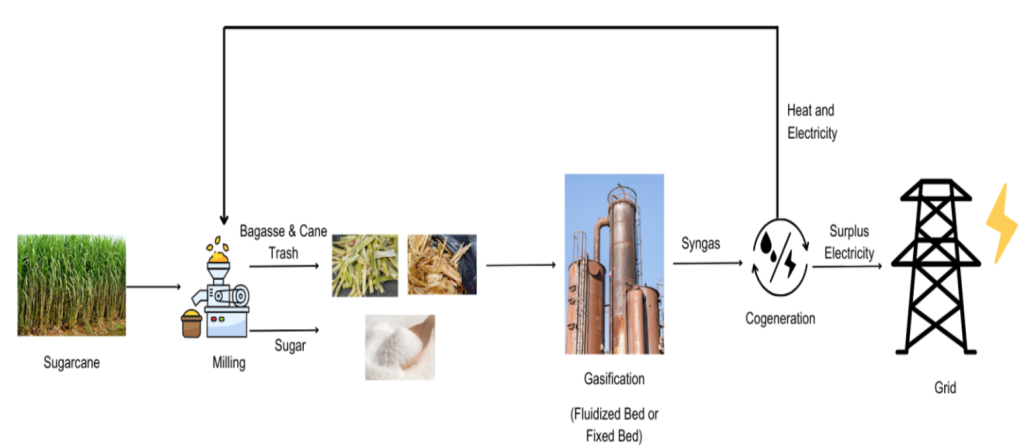

- Cogeneration of Power: In some cases, used for power generation in sugar mills, significantly reducing energy deficits and generating additional power for export.

- Mulching: Applied as mulch in fields to retain moisture, control weeds, and enhance soil fertility.

- Animal Fodder: Used as feed, though less commonly due to high silica and lignin content.

Emerging Uses

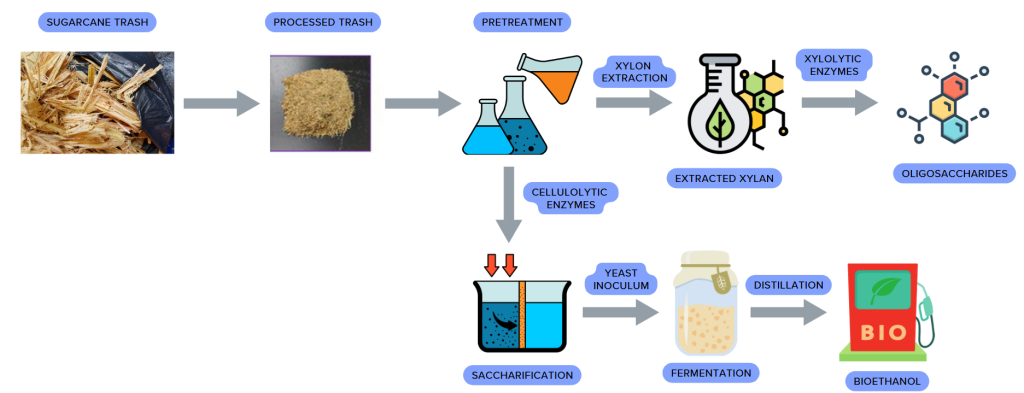

- Ethanol Production: Processed into second-generation ethanol, particularly from the dry leaves, providing a sustainable biofuel option.

- Biochemical Conversion: Utilised in anaerobic digestion for biogas production, leveraging its high carbohydrate content.

- Paper Manufacturing: Experiments are being done for using cane trash for paper manufacturing.

Storage of Cane Trash

Proper storage ensures that briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions. In India, sugarcane tops and trash are valuable feedstocks for livestock and bioenergy. Here are key data points on their storage:

- Moisture Content: Sugarcane tops/trash typically have a moisture content of 40-70%. This makes them prone to microbial degradation, requiring proper drying or ensiling.

- Storage Methods:

- Open-air Drying: Used in rural areas, but moisture retention is high, reducing feed quality.

- Baling: Compressed and baled to reduce space. Can be stored for 6-12 months under shed protection.

- Silage: Sugarcane tops are ensiled with additives (e.g., urea) to preserve nutrients. This method can extend storage up to 12-18 months.

- Losses: Improper storage can lead to a 20-25% loss in dry matter over time due to weathering and microbial activity.

- Storage in India: The use of tarpaulin covers and shed storage is common for baled material, reducing losses to 10-15%.

Cane Trash as Feedstock – Key Challenges:

- Collection and Transportation: Cane trash collection faces challenges with high bulk density, requiring larger storage and transportation space.

- Seasonal Availability: Sugarcane harvesting is seasonal, leading to inconsistent availability of tops and trash, affecting year-round feedstock supply for energy or fodder production.

- High Moisture Content: Fresh sugarcane tops contain up to 75% moisture sometimes, which increases drying costs and limits immediate use as fuel without pre-treatment.

- Farmers’ Preference: Farmers often prefer burning the trash in fields for quick soil clearing rather than using it as feedstock, exacerbating air pollution problems and wasting potential energy resources.

Sugarcane Trash for Industrial Heating and Power Generation

Uses of Sugarcane Trash for Industrial Heating and Power Generation

Sugarcane trash has become a valuable resource in India’s energy landscape. Its utilization can be broken down into two primary areas:

- Industrial Heating:

- Sugarcane trash is widely used as a fuel in industrial boilers to generate heat. Its high calorific value makes it an efficient fuel, reducing the dependency on coal, oil, or natural gas.

- Industries like sugar mills, cement, and brick manufacturing utilize sugarcane trash for process heating, reducing carbon emissions and improving energy efficiency.

- Power Generation:

- Sugarcane trash, when combined with bagasse (another by-product from crushed sugarcane), is used in cogeneration plants to produce electricity and steam.

- This biomass-based energy source is a significant contributor to rural electrification, offering a decentralized power supply to remote areas in India.

- According to the Ministry of New and Renewable Energy (MNRE), India has the potential to generate around 10,000 MW of electricity from sugarcane biomass, including trash and bagasse.

Form in Which Sugarcane Trash is Used in Industries

Sugarcane trash undergoes various forms of processing before it can be utilized efficiently:

- Briquettes: Sugarcane trash is compacted into dense briquettes. These briquettes are uniform, easy to handle, and have a high energy density, making them an ideal fuel source for industrial boilers.

- Pellets: Another form of processed sugarcane trash, pellets are smaller, cylindrical forms of compressed trash. They are preferred due to their easy transportation and storage capabilities.

- Direct Burning: In some industries, sugarcane trash is used in its raw form, either chipped or shredded, and directly burned in boilers. This method is prevalent in rural sugar mills where sophisticated processing equipment may not be available.

Boilers Using Sugarcane Trash

The efficiency of using sugarcane trash in industrial heating largely depends on the type of boilers employed:

- Biomass Boilers: Specifically designed to handle biomass fuels like sugarcane trash, these boilers have advanced combustion chambers to ensure efficient burning and heat generation.

- Fluidized Bed Boilers: These are popular for their ability to handle various types of biomass, including sugarcane trash. They offer high efficiency, lower emissions, and reduced slagging.

- Stoker Boilers: Widely used in sugar mills, stoker boilers have mechanical systems that feed sugarcane trash into the combustion chamber, ensuring uniform burning.

- Co-Generation Boilers: These boilers use both bagasse and sugarcane trash, producing electricity and steam. Sugar mills with cogeneration plants use these boilers to reduce energy costs while exporting surplus power to the grid.

Amount of Sugarcane Trash Being Used by the Industries for Industrial Heating

India produces approximately 65 million tonnes of sugarcane trash annually, of which around 30-35% is currently utilized for industrial heating and power generation. The remaining trash is often burned in the fields, leading to significant air pollution. Efforts are underway to increase the usage rate to reduce environmental impact.

- In regions like Uttar Pradesh, Maharashtra, and Karnataka, sugarcane-growing hubs, an increasing percentage of trash is diverted to biomass-based industries.

- Tamil Nadu is at the forefront, with some sugar mills utilizing up to 70% of available sugarcane trash for energy generation, thanks to efficient cogeneration systems.

Prominent Industries Using Sugarcane Trash for Industrial Heating

Several industries in India have adopted sugarcane trash for its economic and environmental benefits. Key players include:

- Sugar Mills:

- Sugarcane trash is extensively used in sugar mills, especially for co-generation. Leading companies like Bajaj Hindusthan Sugar and Balrampur Chini Mills have adopted cogeneration systems that utilize both bagasse and trash for electricity production and process heating.

- Fact: In 2023, India’s sugar mills generated around 3,000 MW of power using biomass, including sugarcane trash, reducing the reliance on conventional energy sources.

- Paper and Pulp Industries:

- Companies like ITC Ltd. use sugarcane biomass, including trash, as a raw material for producing paper, reducing the demand for wood pulp and contributing to forest conservation.

- This industry has witnessed a shift towards using agricultural residues like sugarcane trash to meet sustainability goals.

- Textile Industry:

- Some Indian textile units use sugarcane trash-based briquettes as an alternative to coal for steam generation during dyeing and finishing processes.

- Cement Industry:

- The Indian cement sector, known for its high energy consumption, has started using sugarcane trash briquettes to reduce carbon emissions. Ultratech Cement and ACC Ltd. have explored biomass-based fuels, including sugarcane trash, to partially replace coal in their kilns.