Key Questions Answered in this Section

- What is the annual wheat straw production in India, and how much of it is currently utilized for industrial purposes?

- How is wheat straw contributing to reducing air pollution and environmental degradation in India?

- What are the key characteristics of wheat straw that make it suitable for industrial heating and power generation?

- How do fluidized bed boilers and stoker boilers handle wheat straw combustion efficiently?

- What challenges do industries face in collecting, storing, and processing wheat straw as a biomass feedstock?

- Why is pelletized or briquetted wheat straw preferred over loose straw for industrial applications?

- How does the use of wheat straw in combined heat and power (CHP) systems improve energy efficiency?

- What role does the Indian textile and food processing industry play in adopting wheat straw-based biomass boilers?

- How are innovative technologies like gasification boilers revolutionizing wheat straw utilization in power generation?

- What are the economic and environmental benefits of scaling up wheat straw utilization in industries across India?

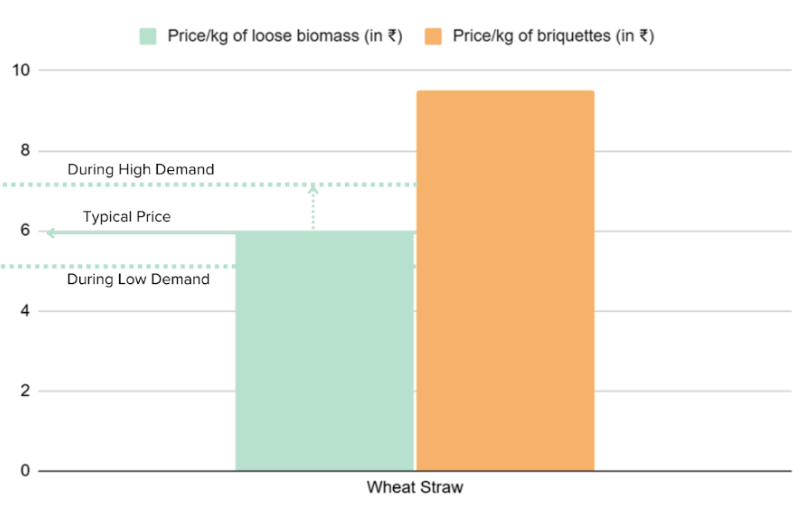

- How is the price of wheat straw determined in both loose and briquette forms, and what factors influence its cost?

- Is it possible to directly use wheat straw in boilers?

Introduction

Wheat straw, the dry residue left after harvesting wheat, is one of India’s most abundant agricultural byproducts, with annual production exceeding 100 million tons. Traditionally treated as waste or used for animal fodder, wheat straw is emerging as a vital biomass feedstock due to its high cellulose (30-45%) and hemicellulose (20-25%) content. In India, it holds immense potential for bioenergy applications, such as bioethanol production, biogas, and direct combustion for power generation.

Utilizing wheat straw as a biomass feedstock addresses multiple challenges: it reduces the environmental impact of open-field burning, curbs air pollution, and provides an additional income stream for farmers. Additionally, wheat straw is a key raw material for producing biochemicals, bio-based plastics, and composite materials, supporting India’s goals for renewable energy and sustainable development.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Let us look into the price, availability, and proximate analysis of wheat straw briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Total Wheat Straw Generation in India

India generates about 110 million tonnes of wheat straw annually, making it one of the largest sources of agricultural residue in the country. A significant portion of this biomass is underutilized, with much of it either left in the fields or burned, contributing to severe air pollution.

Assessing the availability of wheat straw involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of wheat straw reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Parameter | Loose Form | Briquette Form |

| Gross Calorific Value (GCV) | —— | 3700 Kcal/kg |

| Moisture Content | 12% | 8% |

| Ash Content | 7% | 5.5% |

| Silica Content | 5-8% | 5-8% |

| Volatile Matter | 74% | — |

| Fixed Carbon | 16.5% | — |

| Bulk Density | 150-200 Kg/m3 | 625-675 Kg/m3 |

| Price | ₹5-7/kg | ₹9.5/kg |

Seasonality

| Region | Sowing Months | Harvesting Months |

| Karnataka | September-October | January-February |

| Maharashtra | ||

| Andhra Pradesh | ||

| Madhya Pradesh | ||

| West Bengal | ||

| Bihar | October-November | February-March |

| Uttar Pradesh | ||

| Punjab | ||

| Haryana | ||

| Rajasthan | ||

| Himachal Pradesh | November-December | April-May |

| Jammu & Kashmir |

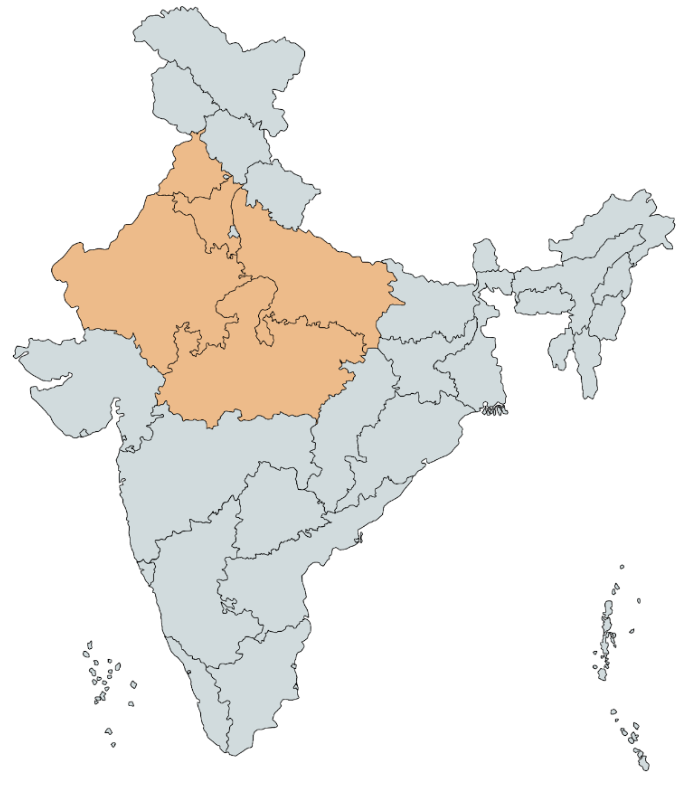

Regional Availability

Regions with abundant wheat straw availability can leverage this resource for use in boilers, promoting sustainable energy practices.

| State | Annual Wheat Production (MTPA) | Annual Wheat Straw Generation (MTPA) | Key Regions of State |

| Uttar Pradesh | 34 | 26 | Azamgarh, Barabanki, Siddharth Nagar, Jaunpur and Gorakhpur |

| Madhya Pradesh | 22.5 | 17 | Sehore, Narsinghpur, Narmadapuram, Hoshangabad, Harda, Ashoknagar, Bhopal and Malwa regions. |

| Punjab | 15 | 11.5 | Faridkot, Ludhiana, Fatehgarh Sahib, Moga, Barnala |

| Haryana | 10.5 | 8 | Sims, Hisar, Bhiwani, Faridabad |

| Rajasthan | 9.5 | 7.3 | Sri Ganganagar, Udaipur, Alwar, Hanumangarh |

Prices

- Loose Form: Wheat straw in loose form is priced between ₹5-7 per kg, making it a more economical option compared to the briquette form.

- Briquette Form: Briquetted wheat straw is priced at ₹9.5 per kg, reflecting the added processing and density benefits for storage and transport.

- Fluctuations in wheat straw price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

Uses of Wheat Straw

- Animal Feed: Chopped wheat straw (bhusa) is a staple feed for ruminants, offering roughage and energy.

- Thatching Material: Long, unchopped wheat straw is used by farmers as an affordable material for thatching roofs.

- Mushroom Cultivation: Wheat straw provides an ideal substrate for growing mushrooms like Pleurotus, due to its fibrous structure

- Covering Material: Used to cover straw storage structures (bonga), protecting stored straw from environmental elements.

Wheat Straw as Feedstock – Key Challenges

- Collection and Transportation:

- Labor-Intensive: Harvesting and collecting wheat straw require significant labor, particularly in rural areas where labor availability may fluctuate.

- Logistical Issues: Transporting straw from the fields to processing facilities can be complicated due to its bulkiness, leading to increased transportation costs.

- Storage Issues:

- Degradation: Wheat straw is susceptible to moisture absorption, which can lead to mold growth, spoilage, and loss of energy content during storage.

- Space Requirements: Large volumes of straw require substantial storage space, which may not be available or economically viable for small farmers. Proper storage ensures that wheat straw briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

- Processing Challenges:

- Size Reduction: Wheat straw must be processed (chopped or ground) before it can be effectively used for energy production, which requires additional machinery and energy.

- Ash Content: Wheat straw has a relatively high ash content, which can lead to problems in combustion efficiency, emissions, and equipment fouling in boilers or furnaces.

- Quality Variability:

- Nutritional Content: The quality of wheat straw can vary significantly based on factors such as the variety of wheat, growing conditions, and harvesting practices, affecting its energy yield.

- Contamination: Straw may be contaminated with soil, seeds, or other organic matter, which can affect the quality of the biomass and complicate processing.

- Environmental Concerns:

- Soil Depletion: Excessive removal of straw from fields can lead to soil degradation and nutrient depletion, impacting future crop yields.

- Air Pollution: Open burning of wheat straw, commonly practiced in some regions for disposal, contributes to air pollution and poses health risks.

Wheat Straw for Industrial Heating and Power Generation

Uses of Wheat Straw for Industrial Heating and Power Generation

Wheat straw, an abundant byproduct of wheat cultivation, is increasingly being utilized in the following ways:

- Biomass Boilers: Many industries are adopting biomass boilers that utilize wheat straw as a primary fuel source. These boilers convert straw into heat energy, making them an eco-friendly alternative to fossil fuels.

- Electricity Generation: Wheat straw is processed in biomass power plants to generate electricity. The combustion of straw releases steam that drives turbines, producing electricity with a significantly lower carbon footprint than traditional sources.

- Combined Heat and Power (CHP) Systems: CHP systems harness the heat generated from burning wheat straw to produce both electricity and useful heat for industrial processes, enhancing energy efficiency.

- Pellet Production: Wheat straw can be compressed into pellets, which are easier to handle and transport. These pellets serve as a consistent fuel source for heating and energy generation.

Form in which Wheat Straw is Used in Industries

In industrial settings, wheat straw is primarily used in the following forms:

- Loose Straw: Often used in traditional biomass boilers, loose straw is fed directly into combustion chambers. Its bulkiness can require larger storage spaces but is straightforward to use.

- Chopped Straw: Chopped into smaller pieces, this form allows for more efficient combustion and better mixing in biomass boilers.

- Pellets: Pelletized wheat straw is gaining popularity due to its high energy density, uniform size, and ease of transport. It burns more efficiently and produces less ash compared to loose or chopped straw.

- Briquettes: Similar to pellets, briquettes are compressed forms of wheat straw that offer high energy content and can be used in various heating applications.

Boilers Using Wheat Straw

Several types of boilers are designed to utilize wheat straw effectively:

- Fluidized Bed Boilers: These boilers provide excellent combustion efficiency and are well-suited for burning straw due to their ability to handle varying fuel qualities.

- Stoker Boilers: Suitable for large-scale operations, stoker boilers use an automatic feeding system to manage the flow of straw into the combustion chamber, ensuring continuous operation.

- Gasification Boilers: These innovative systems convert straw into synthetic gas (syngas) before combustion, allowing for more efficient energy extraction and lower emissions.

Examples of Industrial Boiler Applications

- Thermax: This Pune-based company manufactures biomass boilers that can utilize agricultural residues, including wheat straw, catering to industries such as textiles and food processing.

- Cheema Boilers: Located in Punjab, Cheema offers a range of biomass boilers specifically designed for burning agricultural waste, including wheat straw.

Amount of Wheat Straw Being Used by Industries for Industrial Heating

According to a 2021 report by the Indian Ministry of Agriculture, India generates approximately 140 million tonnes of wheat straw annually. However, only about 20% of this straw is currently being utilized for industrial purposes. The remaining straw often contributes to environmental issues, such as air pollution from burning in the fields.

As industries increasingly adopt biomass solutions, the demand for wheat straw is expected to rise. Projections suggest that by 2025, the utilization of wheat straw in industrial heating and power generation could increase to around 30 million tonnes annually.

Prominent Industries Using Wheat Straw for Industrial Heating

Several key sectors are leading the way in utilizing wheat straw for energy generation:

- Textile Industry: With significant energy demands, the textile sector is turning to biomass boilers that use wheat straw to reduce dependence on fossil fuels.

- Food Processing: This industry generates substantial waste heat, which can be efficiently met by using wheat straw in biomass boilers.

- Pulp and Paper: The pulp and paper industry is exploring biomass as a cost-effective and sustainable alternative for energy generation, thereby lowering operational costs.

- Brick Manufacturing: Brick kilns are increasingly using wheat straw as an alternative fuel source, which not only reduces fuel costs but also helps in managing agricultural waste.

- Power Generation: Several biomass power plants in states like Punjab and Haryana are dedicated to using wheat straw, contributing to renewable energy targets set by the Indian government.