Key Questions Answered in this Section

- How much soybean stalk biomass is produced annually in India?

- What are the key characteristics of soybean stalks in loose and briquette forms?

- Why are soybean stalks suitable for bioenergy applications like biogas and bioethanol production?

- What are the primary challenges in collecting, transporting, and storing soybean stalk biomass?

- Which Indian states produce the most soybean stalk biomass, and what are the key regions?

- How are soybean stalks used in industrial heating and power generation?

- What forms of soybean stalk biomass are utilized in industries, and why?

- What types of boilers are suitable for burning soybean stalks in industrial applications?

- How does the use of soybean stalk biomass compare to traditional fuels like coal in terms of cost and environmental impact?

- Is it possible to directly use soybean stalks in boilers?

Introduction

Soybean stalk biomass feedstock refers to the non-grain portion of the soybean plant, primarily the stalks, stems, and leaves, which are left over after the soybean seeds are harvested. This lignocellulosic biomass is composed mainly of cellulose, hemicellulose, and lignin—key components that make it suitable for various bioenergy applications.

Expert Consulting Assistance for Indian Bioenergy & Biomaterials

Talk to BioBiz

Call Muthu – 9952910083

Email – ask@biobiz.in

Typically, soybean stalks have a high carbon content and moderate nitrogen levels, which make them an excellent feedstock for producing biofuels like cellulosic ethanol, biogas through anaerobic digestion, and biochar for soil amendment and carbon sequestration.

The high fiber content of soybean stalks allows for efficient conversion to bioenergy, while the presence of secondary compounds like proteins and minerals makes it a potentially useful material for bioproducts such as bioplastics and animal feed additives. Let us look into the price, availability, and proximate analysis of soybean stalk briquettes and pellets, their use in boilers, and the role of transport and logistics in their efficient distribution.

Total Soybean Stalk Generation in India

- Soybean generates approximately 23 million tonnes of stalks annually in India.

- This number includes the entire stalk and other plant parts left over after harvest.

Assessing the availability of soybean stalk involves analyzing its proximate analysis to determine suitability for various applications.

Biomass Characteristics

The table summarizes proximate analysis (moisture, volatile matter, ash, fixed carbon) and feedstock costs, highlighting quality and economic feasibility. The proximate analysis of soybean stalk reveals its efficiency when used in boilers, highlighting its potential as a renewable energy source.

| Characteristic | Loose Form | Briquette Form |

| Gross Calorific Value | —– | 3800 Kcal/kg |

| Moisture Content | 15% | 10% |

| Ash Content | 5% | 5% |

| Silica Content | 2-5% | 2-5% |

| Volatile Matter | 82% | 80% |

| Fixed Carbon | 7% | 10% |

| Bulk Density | 260 Kg/m3 | 655 Kg/m3 |

| Price | ₹2.5-3.5 per kg | ₹6.5 per kg |

Seasonality

- Soybean is primarily a Kharif crop, meaning it is cultivated during the monsoon season from July to October.

- The crop is predominantly grown in rainfed areas across central and peninsular India.

- The key soybean-growing states are:

- Madhya Pradesh

- Maharashtra

- Andhra Pradesh

- Gujarat

- Karnataka

- Rajasthan

- Chhattisgarh

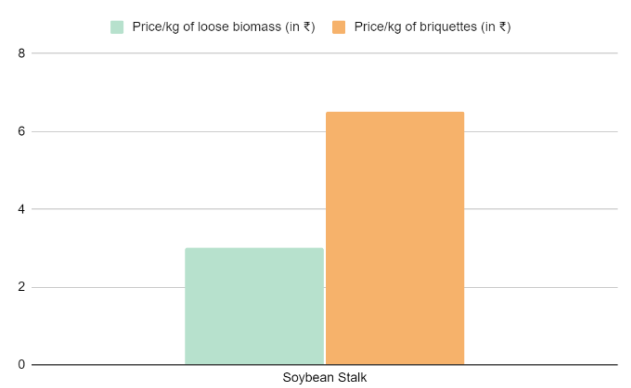

Prices

- Raw Biomass: The price of loose soybean stalks in India ranges from ₹2.5 to ₹3.5 per kg.

- Briquettes: If converted into briquettes, the price increases to approximately ₹6.5 per kg.

- Fluctuations in soybean stalk price directly impact the cost-effectiveness of producing briquettes and pellets for industrial boiler use.

Regional Availability

Regions with abundant soybean availability can leverage this resource for use in boilers, promoting sustainable energy practices.The following are the top five states in India where soybean is abundantly available, along with key regions within those states.

| State | Total Crop Production in MTPA | Key regions |

| Maharashtra | 5.5 | Yavatmal, Amravati, Buldhana, Nagpur, Wardha, Chandrapur |

| Madhya Pradesh | 5.4 | Ujjain, Hoshangabad, Guna, Indore, Sagar, Rajgarh |

| Rajasthan | 0.9 | Jhalawar, Bundi, Kota, Chittorgarh, Banswara, Baran |

| Karnataka | 0.4 | Bidar, Belgaum, Haveri, Dharwad |

| Gujarat | 0.35 | Saurashtra, Junagadh, Aravali, Dahod, Chhota Udepur |

Storage

- Storage Conditions: Soybean stalks are usually stored in dry and well-ventilated areas to prevent moisture accumulation, which can lead to fungal growth and spoilage. Ideal moisture content for storage is below 15%.

- Baled Storage: Stalks are often stored in the form of bales (rectangular or round). A typical round bale weighs about 250–400 kg. Baled stalks take up less space and are easier to handle.

- Storage Duration: If stored under proper conditions (low humidity and covered), soybean stalks can be preserved for up to 1 year without significant nutritional losses.

- Loss Rates: Improper storage can lead to losses of up to 30–50% due to exposure to rain, pests, or decay. Covered or shed storage can reduce this to 5–10%.

- Harvesting Seasons: Soybean is typically harvested in October-November in India. Immediate post-harvest baling and storage are crucial to preserve the stalks’ quality.

- Proper storage ensures that soybean stalk briquettes and pellets maintain their quality, facilitating efficient transport and logistics to various regions.

Uses of Soybean Stalk

Current Uses

- Animal Feed: Soybean stalk has witnessed a good demand as animal feed in some regions

- Animal Bedding: Baled and used as absorbent bedding for livestock, offering a cost-effective and sustainable solution

- Soil Protection: Left in fields as residue to prevent soil erosion and improve soil organic matter.

Emerging Uses

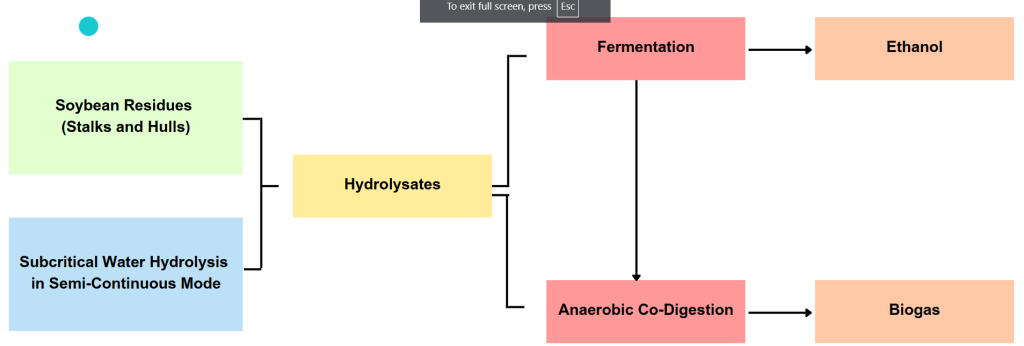

- Biogas Production: Utilised in anaerobic digestion to produce biogas, especially after pretreatment to improve yield.

Soybean Stalk as Feedstock – Key Challenges

- Limited Collection Infrastructure: Approximately 10-20% of soybean stalks are collected due to inadequate machinery and labor. This low collection rate results in high post-harvest losses.

- High Transportation Costs: Biomass transport is expensive, with logistics contributing to 35-50% of overall costs due to the low bulk density of soybean stalks.

- Seasonal Availability: Soybean stalks are only available post-harvest (October-November), limiting year-round supply for biomass-based industries.

- Competition with Other Uses: Soybean stalks are often used as animal fodder or burned in fields, reducing availability for industrial purposes.

- Lack of Commercial Viability: The market for soybean stalk biomass is still underdeveloped, with a lack of standardized pricing and formal market channels.

- Low Calorific Value: Soybean stalks have a calorific value lower than other biomass sources like wood, reducing their appeal for energy production.

Soybean Stalk for Industrial Heating and Power Generation

Uses of Soybean Stalk for Industrial Heating and Power Generation

Soybean stalk is a promising biomass fuel that provides a sustainable alternative to traditional fossil fuels. Here are some key applications:

- Direct Combustion for Industrial Heating: Indian industries use soybean stalks as a direct combustion fuel in boilers, generating the necessary steam and heat for various industrial processes. This method is cost-effective and reduces dependence on conventional fuels like coal.

- Co-Firing in Thermal Power Plants: In India, several thermal power plants are now incorporating soybean stalks alongside coal in a process known as co-firing. This not only decreases carbon emissions but also ensures efficient utilization of agricultural waste.

- Pellet Production for Power Generation: Soybean stalks are compressed into pellets, which can be used as a clean-burning fuel. These pellets are utilized in specialized biomass boilers and provide a steady, high-energy source for power generation, especially in rural and semi-urban industries.

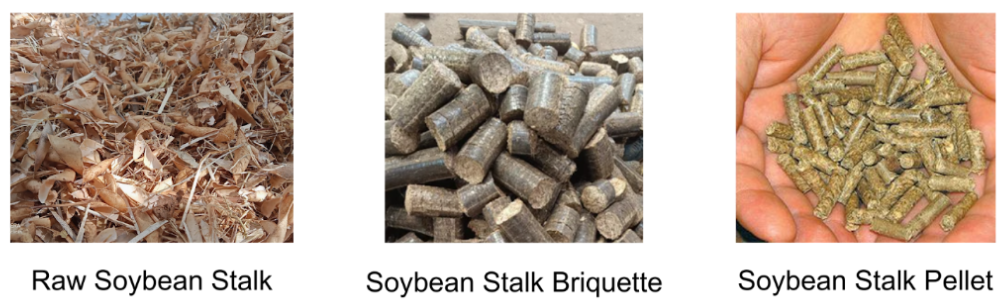

Forms in Which Soybean Stalk is Used in Industries

Industries in India utilize soybean stalk in the following processed forms:

- Raw Stalks: Harvested and dried stalks are directly burned in boilers, a common practice among smaller-scale industries due to minimal processing costs.

- Chipped or Shredded Biomass: Soybean stalks are shredded into smaller pieces to improve combustion efficiency. This form is preferred for consistent heating requirements.

- Briquettes and Pellets: One of the most efficient forms, briquettes and pellets are made by compressing soybean stalks. They have a higher calorific value and lower moisture content, making them ideal for large-scale industrial heating and biomass power plants.

- Biogas Production: Soybean stalk can also be used in biogas plants. Through anaerobic digestion, it produces biogas—a clean and renewable energy source, though not as widespread as direct combustion or pellet use.

Boilers Using Soybean Stalk in India

The adoption of soybean stalk as a biomass fuel has led to the development and use of specialized boilers. Key types include:

- Biomass Boilers: These boilers are designed to burn agricultural residues, including soybean stalks. They are widely used in food processing, textile, and chemical industries in India.

- Fluidized Bed Combustion (FBC) Boilers: In these boilers, soybean stalks are burned in a bed of hot, inert material like sand. This technology ensures efficient combustion and can handle the varying moisture content of agricultural residues, including soybean stalk.

- Chain Grate Boilers: Some industries utilize chain grate boilers that are well-suited for burning soybean stalk briquettes. These boilers provide consistent heat output, making them ideal for industrial applications requiring steady steam generation.

Amount of Soybean Stalk Being Used by Industries for Industrial Heating

While precise data on soybean stalk usage in India can be scarce, estimates indicate that the trend is steadily rising:

- Maharashtra and Madhya Pradesh, two of the leading soybean-producing states in India, account for about 60-70% of the country’s total soybean biomass utilization.

- On average, 23 million tonnes of soybean stalk are generated annually in India, with an increasing portion dedicated to energy production.

- Recent surveys suggest that 15-20% of the generated biomass from soybean stalks is now redirected to industrial heating and power generation, a figure expected to grow due to rising fuel costs and eco-friendly initiatives.

Prominent Industries Using Soybean Stalk for Industrial Heating

Several industries across India have started harnessing soybean stalks for their heating and energy needs, including:

- Textile Industry: Textile factories, particularly in Gujarat and Tamil Nadu, are using biomass boilers powered by soybean stalks to generate the steam required for dyeing and washing processes.

- Food Processing: In Madhya Pradesh, the heartland of soybean cultivation, food processing units utilize soybean stalk-based boilers to ensure a constant supply of heat while reducing operational costs.

- Sugar Mills: Maharashtra’s sugar mills have begun using soybean stalks in co-firing processes. The initiative is part of the state’s biomass power policy to reduce carbon footprints in the industry.

- Agro-Based Industries: Factories that produce fertilizers, oils, and animal feed often use soybean stalks for thermal energy, primarily because of the ease of access to this biomass in rural areas.